Panasonic Corporation Automation Controls Business Unit industrial.panasonic.com/ac/e ACCTB13E 201201-T

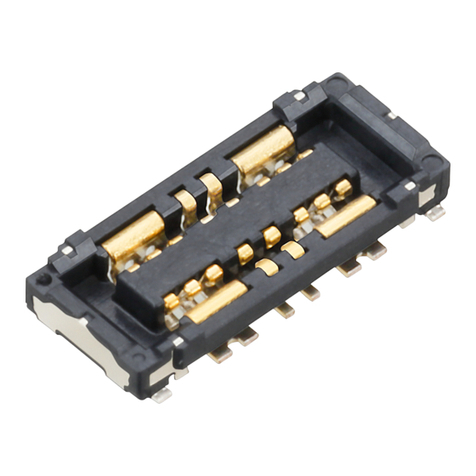

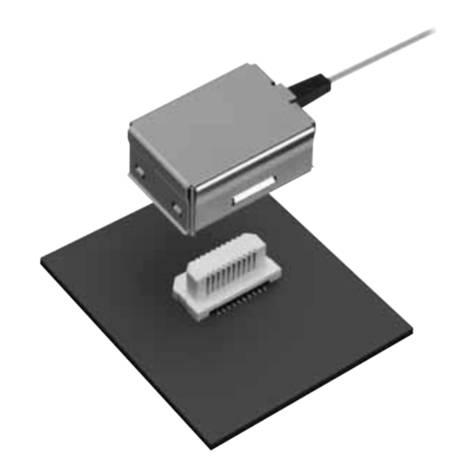

NOTES FOR USING FPC CONNECTORS

(Common)

PC board design

Design the recommended foot pattern in

order to secure the mechanical strength

in the soldered areas of the terminal.

FPC and equipment design

Design the FPC based with

recommended dimensions to ensure the

required connector performance.

Due to the FPC size, weight, or the

reaction force of the routed FPC.

Carefully check the equipment design

and take required measures to prevent

the FPC from being removed due to a fall,

vibration, or other impact.

Connector mounting

Excessive mounter chucking force may

deform the molded or metal part of the

connector. Consult us in advance if

chucking is to be applied.

Soldering

1) Manual soldering.

• Due to the connector’s low profile, if an

excessive amount of solder is applied

during manual soldering, the solder may

creep up near the contact points, or

solder interference may cause imperfect

contact.

• Make sure that the soldering iron tip is

heated within the temperature and time

limits indicated in the specifications.

• Flux from the solder wire may adhere to

the contact surfaces during soldering

operations. After soldering, carefully

check the contact surfaces and clean off

any flux before use.

• Be aware that a load applied to the

connector terminals while soldering may

displace the contact.

• Thoroughly clean the iron tip.

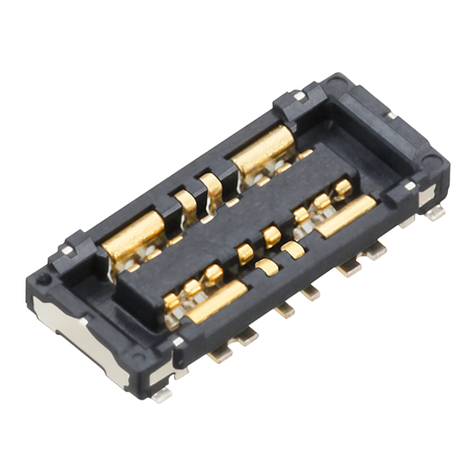

2) Reflow soldering

• Screen-printing is recommended for

printing paste solder.

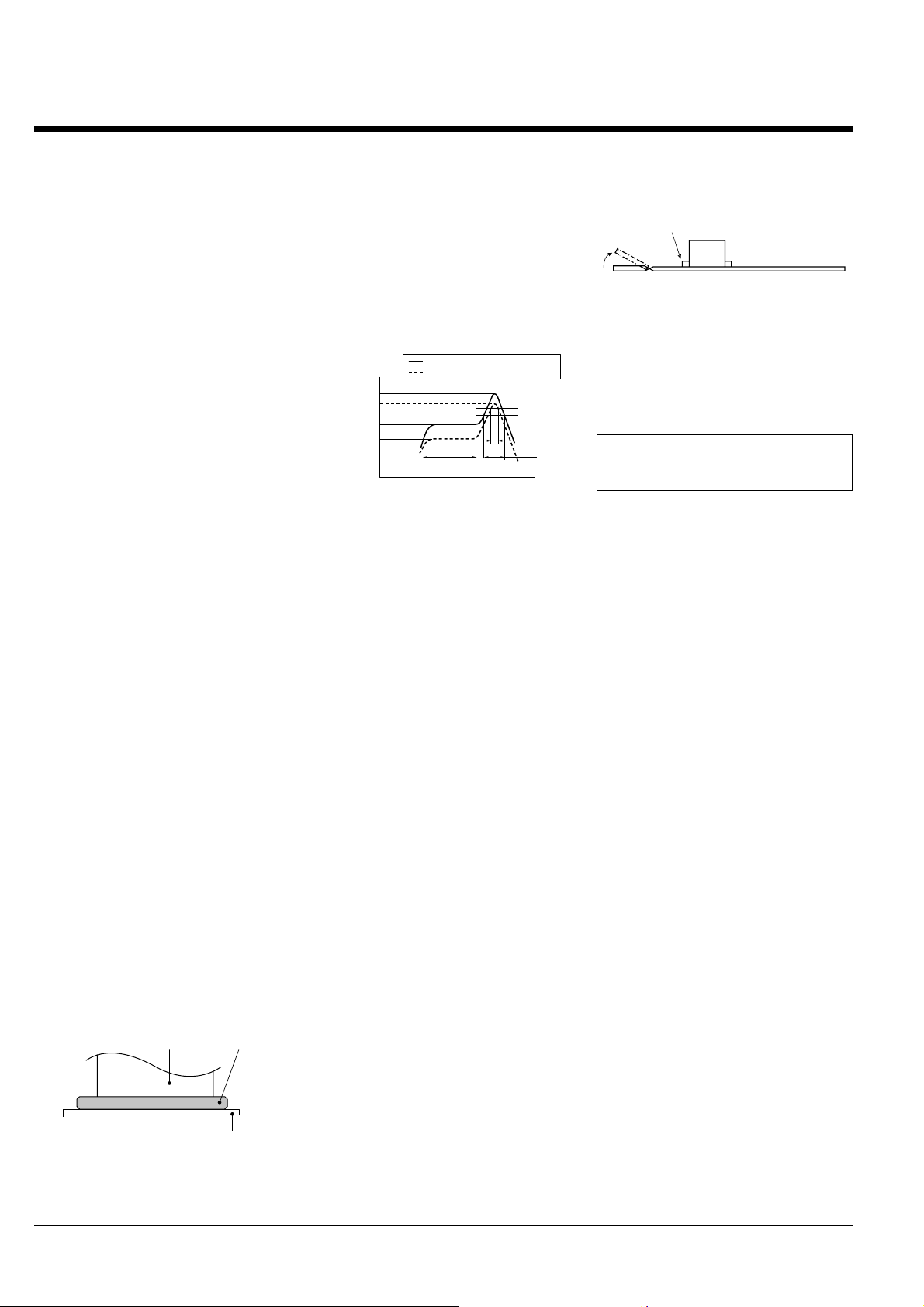

• To determine the relationship between

the screen opening area and the PC

board foot pattern area, refer to the

diagrams in the recommended patterns

for PC boards and metal masks when

setting.

• Note that excess solder on the terminals

prevents complete insertion of the FPC,

and that excess solder on the soldering

terminals prevents the lever from rotating.

• Screen thickness of 120µm is

recommended for paste solder printing.

• Consult us when using a screen-printing

thickness other than that recommended.

• Depending on the size of the connector

being used, self alignment may not be

possible. Accordingly, carefully position

the terminal with the PC board pattern.

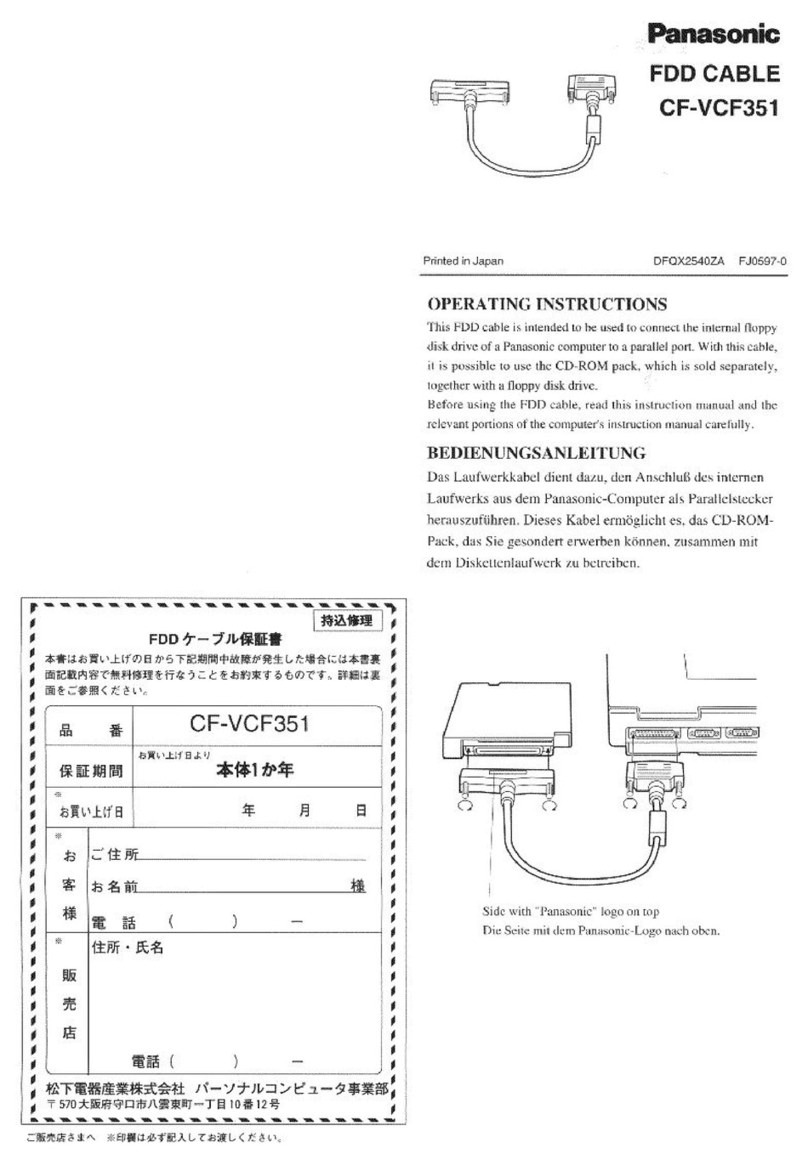

• The recommended reflow temperature

profile is given in the figure below

Recommended reflow temperature

profile

• The temperature is measured on the

surface of the PC board near the

connector terminal.

• Certain solder and flux types may cause

serious solder creeping. Solder and flux

characteristics should be taken into

consideration when setting the reflow

soldering conditions.

• When performing reflow soldering on

the back of the PC board after reflow

soldering the connector, secure the

connector using, for example, an

adhesive. (Double reflow soldering on the

same side is possible)

3) Reworking on a soldered portion

• Finish reworking in one operation.

• For reworking of the solder bridge, use

a soldering iron with a flat tip. Do not add

flux, otherwise the flux may creep to the

contact parts.

• Use a soldering iron whose tip

temperature is within the temperature

range specified in the specifications.

Do not drop or handle the

connector carelessly. Otherwise, the

terminals may become deformed due

to excessive force or applied

solderability may be during reflow

degrade.

Don’t open/close the lever or insert/

remove an FPC until the connector is

soldered. Forcibly applied external

pressure on the terminals can weaken

the adherence of the terminals to the

molded part or cause the terminals to

lose their evenness. In addition, do

not insert an FPC into the connector

before soldering the connector.

When cutting or bending the PC

board after mounting the connector,

be careful that the soldered sections

are subjected to excessive forces.

Other Notes

When coating the PC board after

soldering the connector (to prevent the

deterioration of insulation), perform the

coating in such a way so that the coating

does not get on the connector.

The connectors are not meant to be used

for switching.

Te r minal Paste solder

PC board foot pattern

150°C

180°C

230°C220°C

200°C

260°C

Temperature

Upper limit (Soldering heat resistance)

Lower limit (Solder wettability)

Preheating

Peak temperature

Time

25 sec.

70 sec.60 to 120 sec. Please refer to the latest product

specifications when designing your

product.

The soldered areas should not be subjected to forces.