Parker ULRM 004 Maintenance and service guide

Other Parker Accessories manuals

Parker

Parker Hypercool WR 007 Series User manual

Parker

Parker 162703ECD User manual

Parker

Parker SensoNODE Gold User manual

Parker

Parker GS100 User manual

Parker

Parker TGSS User manual

Parker

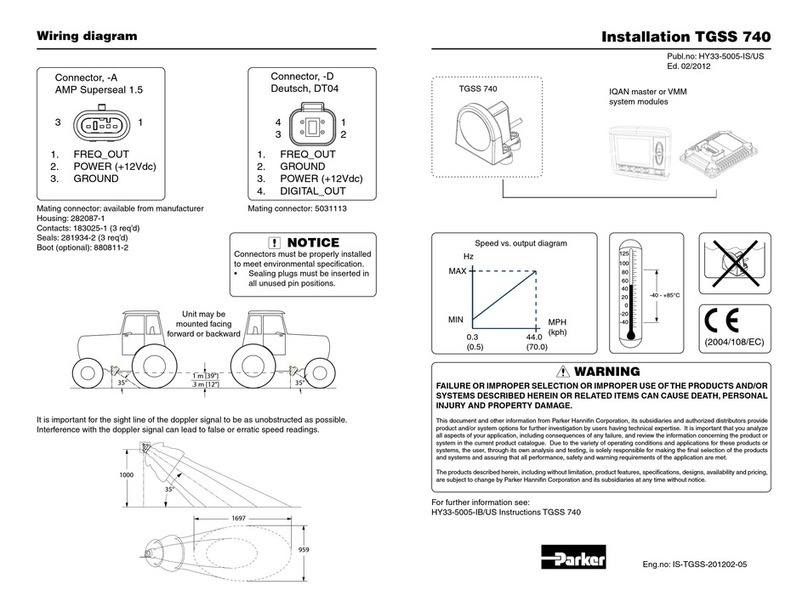

Parker TGSS 740 User manual

Parker

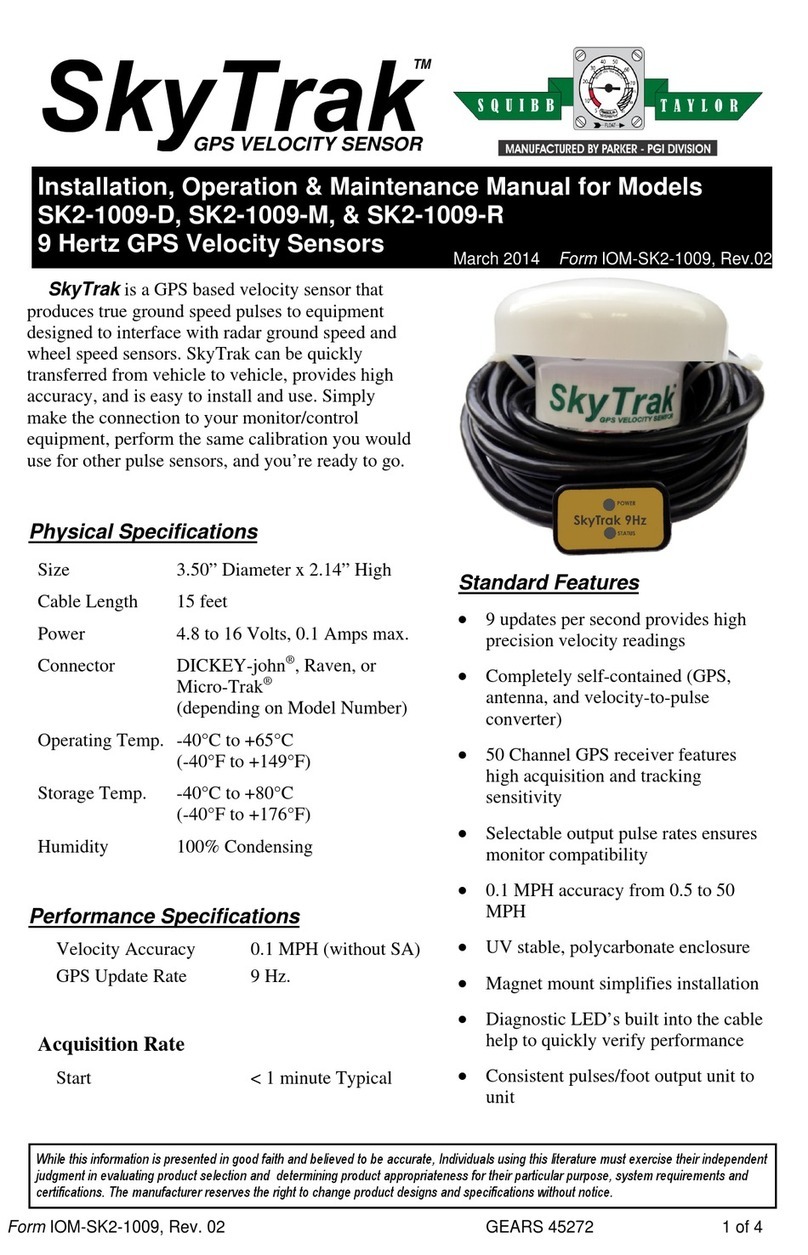

Parker Squibb Taylor SkyTrak SK2-1009-D Instruction manual

Parker

Parker UTS-G User manual

Parker

Parker SciLog SciPres Assembly instructions

Parker

Parker 023-0475 User manual

Parker

Parker SensoControl User manual

Parker

Parker PJC Series User manual

Parker

Parker Airtek ACR1600 User manual

Parker

Parker SciLog WeighStation Assembly instructions

Parker

Parker UTS-ID User manual

Parker

Parker RK 11-1570 User manual

Parker

Parker TGSS 740 User manual

Parker

Parker QAC Datasheet

Parker

Parker TGSS 740 User manual

Parker

Parker Sporlan SD-245 User guide