Bulletin 4480-T7-U

arr

krimp

arker Hanni

n

orporation

Pr

t

Divi

i

n

ickli

e,

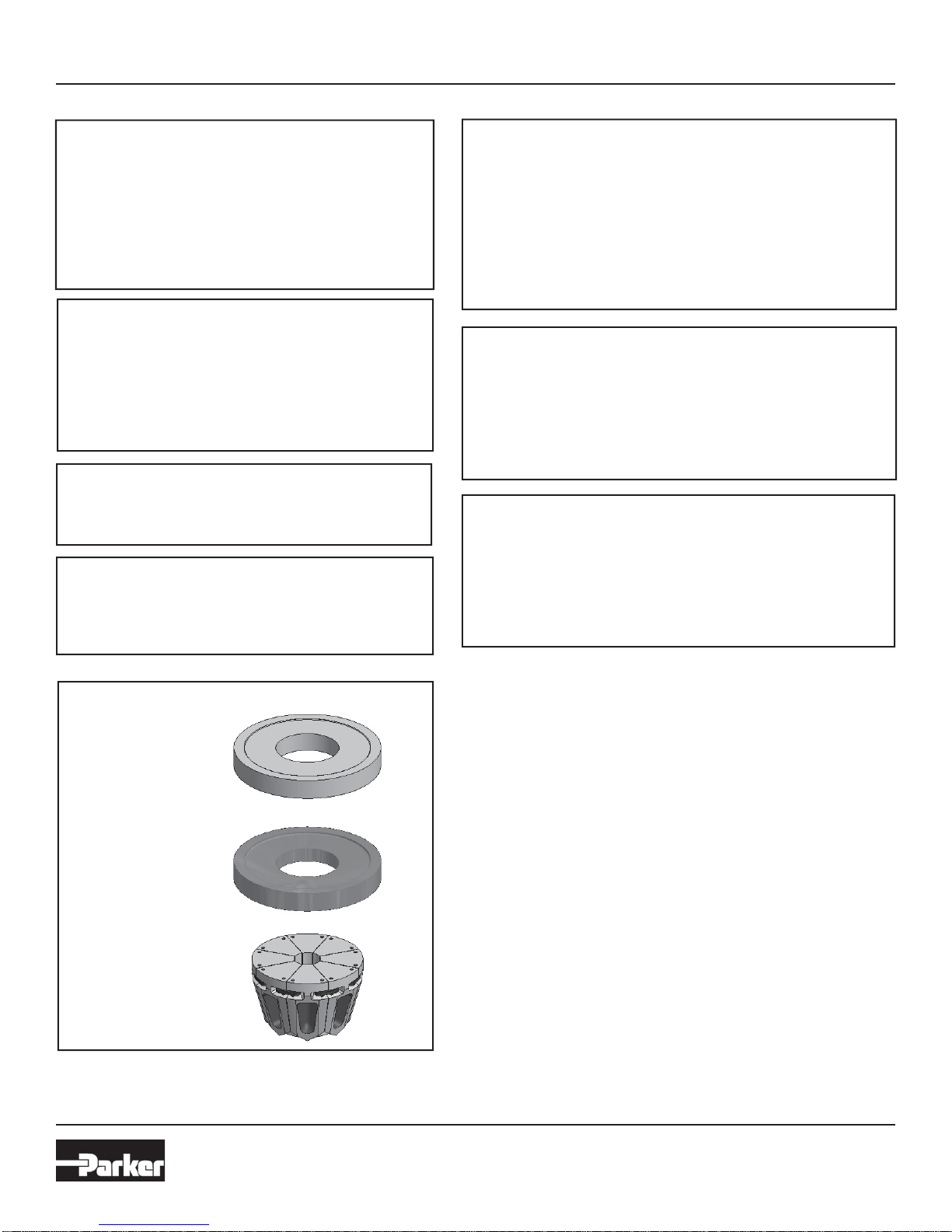

Read the entire Technical Manual prior to mountin

and operatin

this crimper.

View the enclosed video or CD prior to operatin

this crimper

ARNIN

- When usin

this machine, alwa

s exercise basic sa

et

precautions, includin

, but not

limited to the

ollowin

:

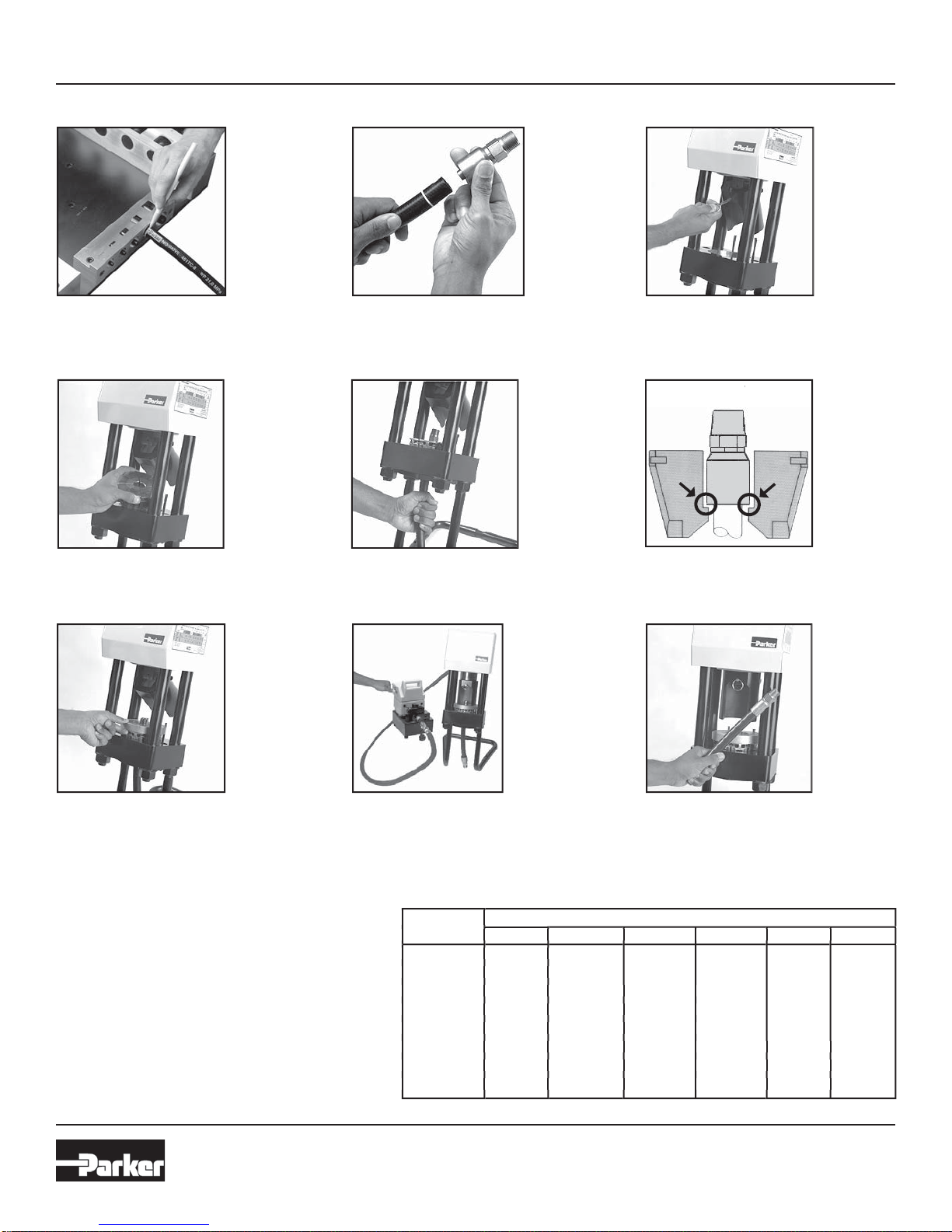

1. Use this machine onl

or its intended purpose: to

abricate Parker hose assemblies.

2. Parker Hanni

n will not accept responsibilit

or an

incidental, consequential or special

dama

es o

an

kind or nature whatsoever that result

rom an

subsequent alterations to an

Parkrimp machine. Parker Hanni

n disclaims an

warranties on items altered a

ter leavin

the

Parker Hanni

n

acilit

.

3. This machine must be properl

installed and located in accordance with the installation

in

tr

ti

n

r

it i

.

To minimize the possibilit

o

in

ur

:

1. The power unit must be connected to a

rounded, properl

rated, protected and sized

power-supp

c

rcu

t to prevent e

ectr

ca

s

oc

an

to avo

e

ectr

ca

over

oa

;

2. D

N

T

PERATE

VER MAXIMUM RATED W

RKIN

PRE

URE; AND

.

HE

K F

R

AFE

Y

TEM

ET

P

Make sure that the valve, connectin

hoses, etc. are protected

rom an

external source o

dama

e, such as: excessive heat,

ame, movin

machine parts, sharp ed

es,

allin

ob

ects,

corros

ve c

em

ca

s, etc.

IMP

RTANT

AFETY N

TI

THI

INF

RMATI

N I

INTENDED F

R U

E BY INDIVIDUAL

P

E

IN

ADE

UATE BA

K

R

UND

F

ELECTRICAL, ELECTR

NIC AND MECHANICAL EXPERIENCE. ANY ATTEMPT T

REPAIR THIS MACHINE MA

ESULT IN PERS

NAL INJURYAND PR

PERTY DAMAGE

THE MAN

FA

T

RER

R

ELLER

ANN

T BE RE

P

N

IBLE F

R THE INTERPRETATI

N

F THI

NF

RMATI

N, N

R CAN ITASSUME ANY LIABILITY IN C

NNECTI

N WITH ITS USE

DI

NNE

TANY P

WER

RD BEF

RE

ERVI

IN

IMP

RTANT - RE

NNE

T ALL

R

NDIN

DEVI

E

© Cop

ri

ht 2005, Parker Hannifin Corporation, All Ri

hts Reserve

Parker

a

et

uide

or

electin

and Usin

Hose, Tubin

, Fittin

s and Related Accessories

Parker Publication No. 44

-B.

Revised: Ma

, 2002

WARNIN

Failure or improper use o

hose, tubin

,

ttin

s, assemblies or related accessories

Products”

can cause death, personal in

ur

and propert

dama

e. Pos-

sible conse

uences of failure or im

ro

er selection or im

ro

er use of these Products include but are not limited to:

e

ore selectin

or usin

an

o

these Products, it is important that

ou read and

ollow the instructions below.

nl

Hose

rom Parker’s

trato

ex Products Division is ap-

roved

or in

i

ht aerospace applications, and no other Hose can be used

or such in

i

ht applications.

• Fittin

s thrown off at hi

h spee

• Hi

h velocit

fluid dischar

e• Explosion or burnin

of conve

ed fluid.• Electrocution from hi

h volta

e electric power lines.• Contact with suddenl

movin

or fallin

ob

ects that are controlled b

the conve

ed fluid.• In

ections b

hi

h-pressure fluid dischar

e.

• Dan

erousl

whippin

Hose.

• Contact with conve

ed fluids that ma

be hot, cold, toxic or otherwise in

urious.

• Sparkin

or explosion caused b

static electricit

buildup or other sources of electricit

• Sparkin

or explosion while spra

in

paint or flammable liquids.

• In

uries resultin

from inhalation, in

estion or exposure to fluids.

er o

al

The items in this document are hereb

offered for sale b

Parker Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are

overned b

the provisions stated in the "

er o

ale"

afet

Notices