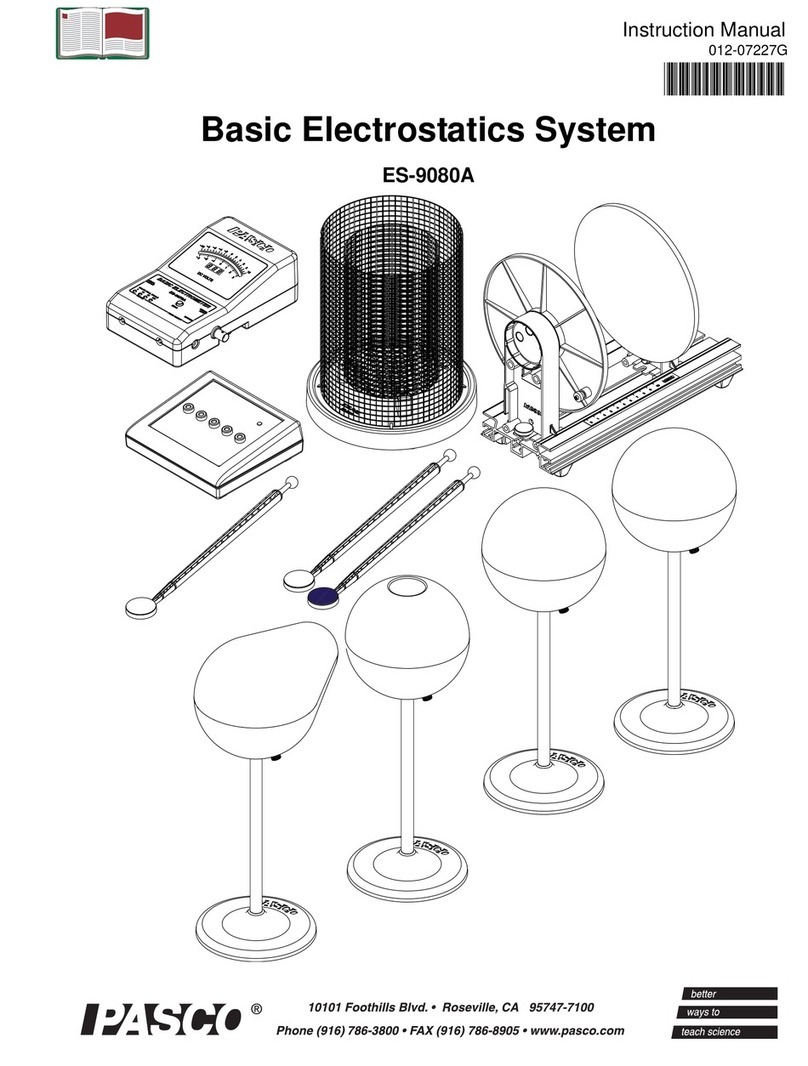

Human Structures Set About theComponents

4012-13878A

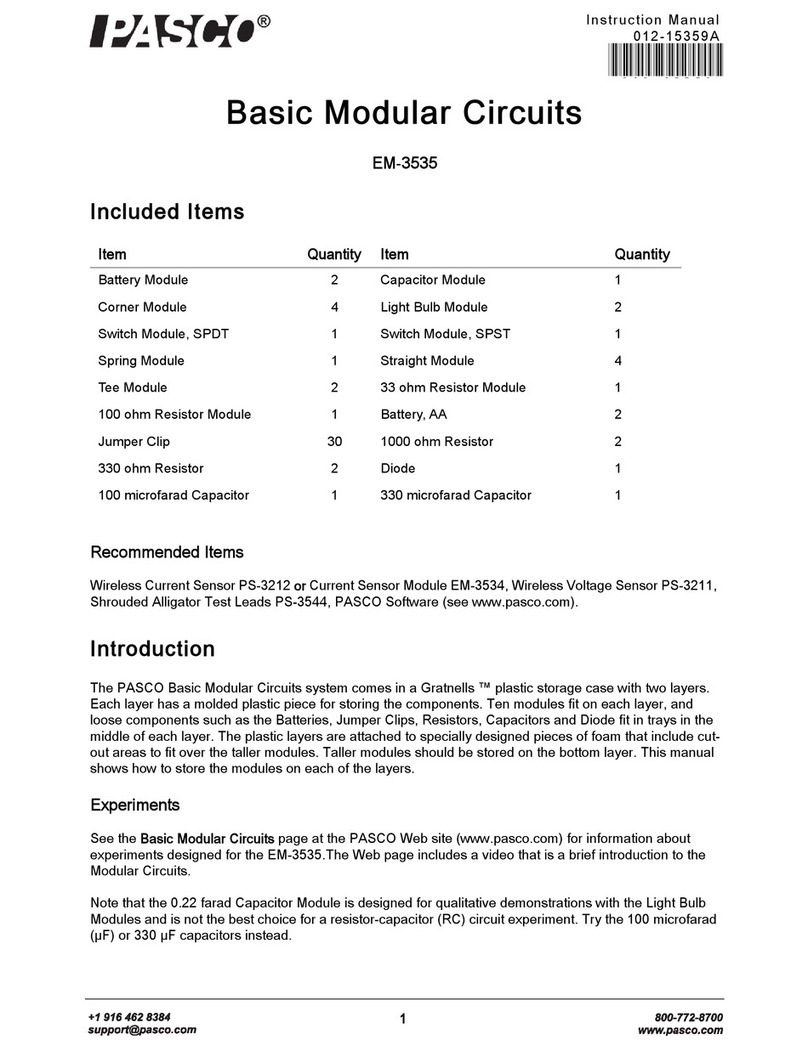

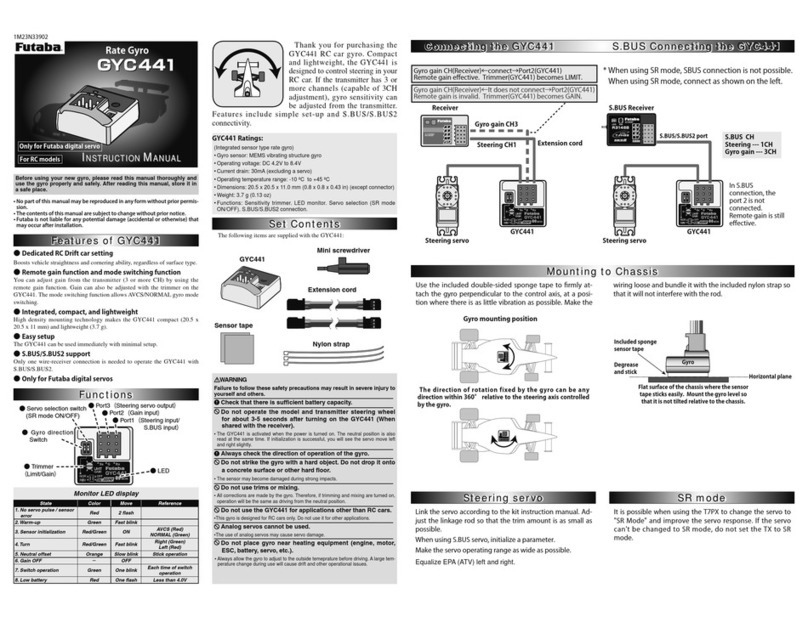

Connectors

Half Round Connector: The half round connector has eight slots, labeled A

through H, for accepting beams.

Full Round Connector: The full round connector has eleven slots, labeled A

through H and X, Y, and Z, for attaching beams

Flat Connector: The flat connector has eight slots, labeled A through E, and X,

Y, and Z, for attaching beams.

Straight Connector: The straight connector can connect two beams to make a

longer beam.

Angle Connector: The angle connector can allow a beam to be connected to a

half round connector, full round connector, or flat connector at an angle differ-

ent than zero, 45, or 90 degrees. The Angle Connector also allows for a small

adjustment of the length of the beam.

Sliding Connector: The sliding connector allows one beam to be connected to

another beam at any position along the length of the second beam. To use the

sliding connector, loosen the thumbscrew and rotate the top “jaw” to the side.

Place the beam onto the lower part of the connector, rotate the top “jaw” into

place, and tighten the thumbscrew.

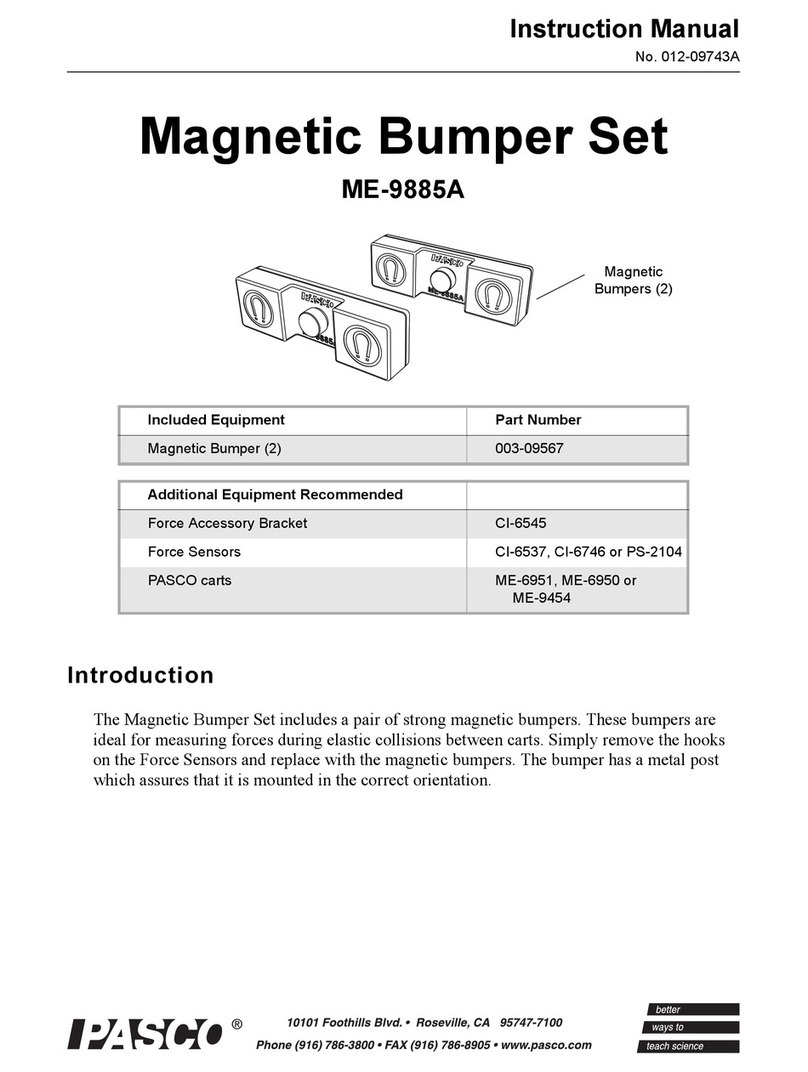

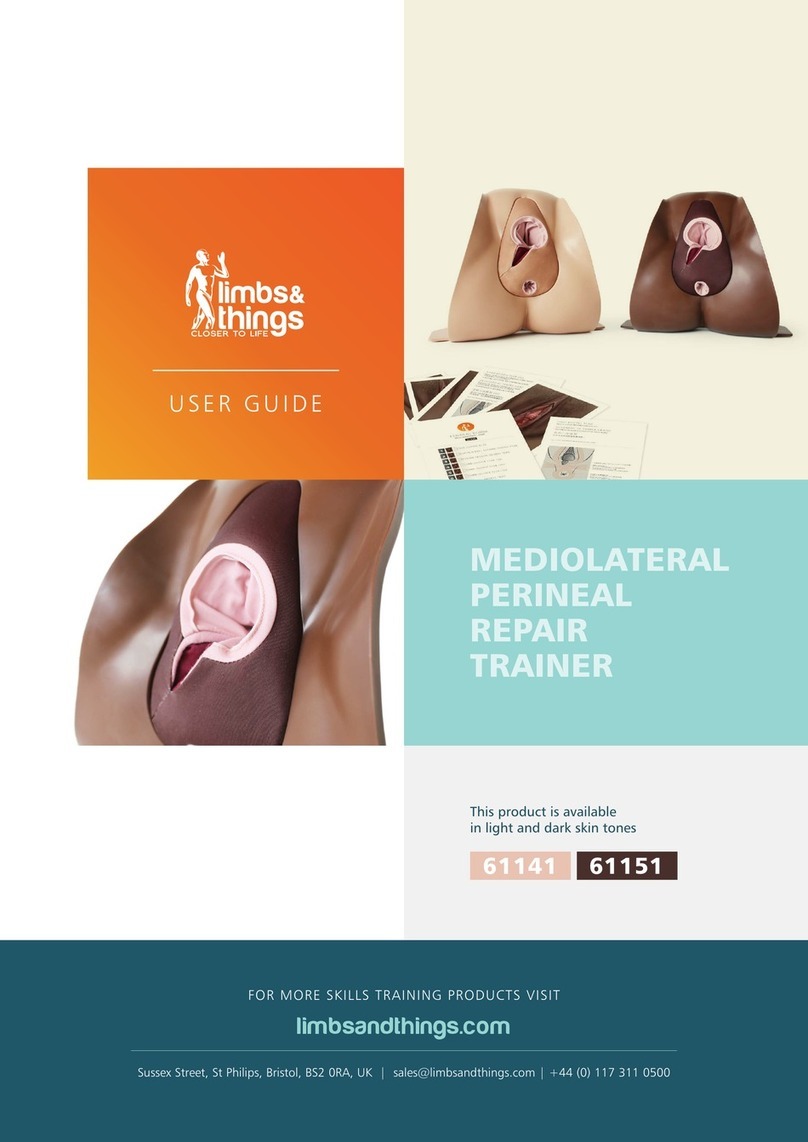

Nut and Bolt for PAStrack: The square nut and bolt can be used with a flat connector to fasten a

structure to a PASCO PAStrack (see the PASCO catalog or web site at www.pasco.com for infor-

mation about PAStrack equipment.)

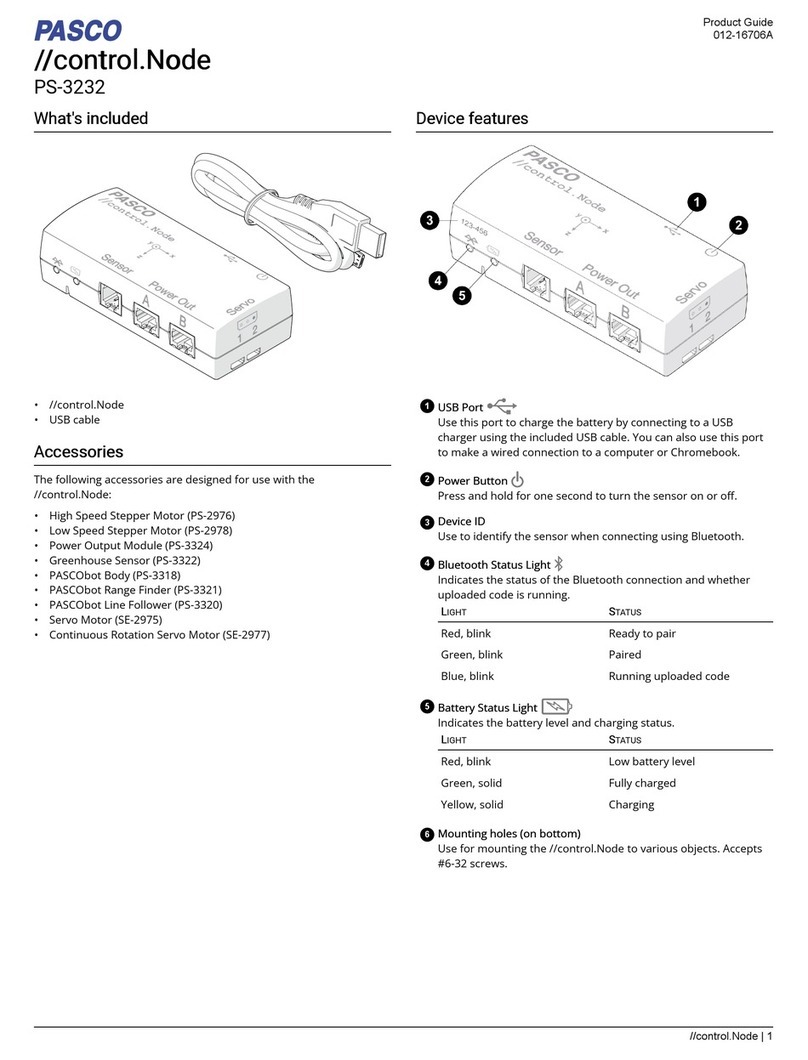

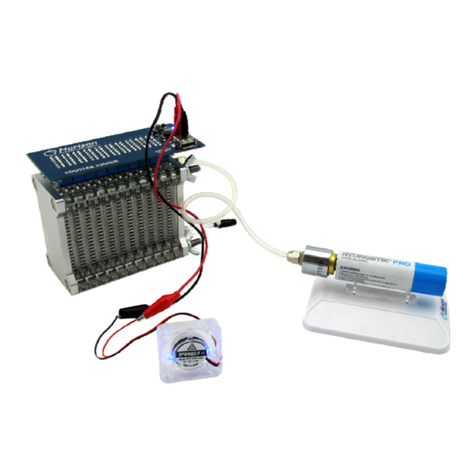

Axles, Pulleys, Spacers, Collets, and Drive Wheels

Axles: There are two each of three different lengths: 10.4 cm (4.1 in), 21.3 cm (8.4

in), and 26.6 cm (10.5 in). Each axle is 0.635 cm (0.250 in) in diameter.

Pulleys: There are twelve pulleys, each 3.175 cm (1.250 in) in diameter and 0.558

cm (0.220 in) wide. To make a wheel, put one of the small “O” rings into the pul-

ley’s groove.

Spacers and Collets: There are twelve spacers, each 0.635 cm (0.250 in) inside

diameter, 1.25 cm (0.50 in) outside diameter, and 0.635 cm (0.250 in) wide.Collets:

There are twenty-four collets that can be used with screws (6-32) to hold pulleys

and spacers in place on an axle.

Drive Wheel with Tire: There are four drive wheels with tires. The drive wheel can

be attached to an axle using a thumbscrew. To attach the wheel firmly to the axle,

line up a hole on the axle with the thumbscrew hole on the wheel. If the rubber tire is removed, the wheel can be used as a

large pulley.

Half Round

Full Round Flat

Straight Angle

Figure 3: Connectors

Sliding

I-Beam #1

“Jaw”

Figure 4: Nut and

Bolt for PAStrack

Figure 5: Axle items

Axle

O-Ring

PulleySpacer

Collet

Drive

Wheel

Top view