3

Table Of Contents

Identication of Machine ...................................................................... 3

Specications............................................................................................. 3

Before You Begin....................................................................................... 4

Safety Precautions.................................................................................... 4

General Guidelines........................................................................ 4

Before Operation ........................................................................... 5

During Operation .......................................................................... 5

Following Operation .................................................................... 5

Pump Safety Precautions............................................................ 5

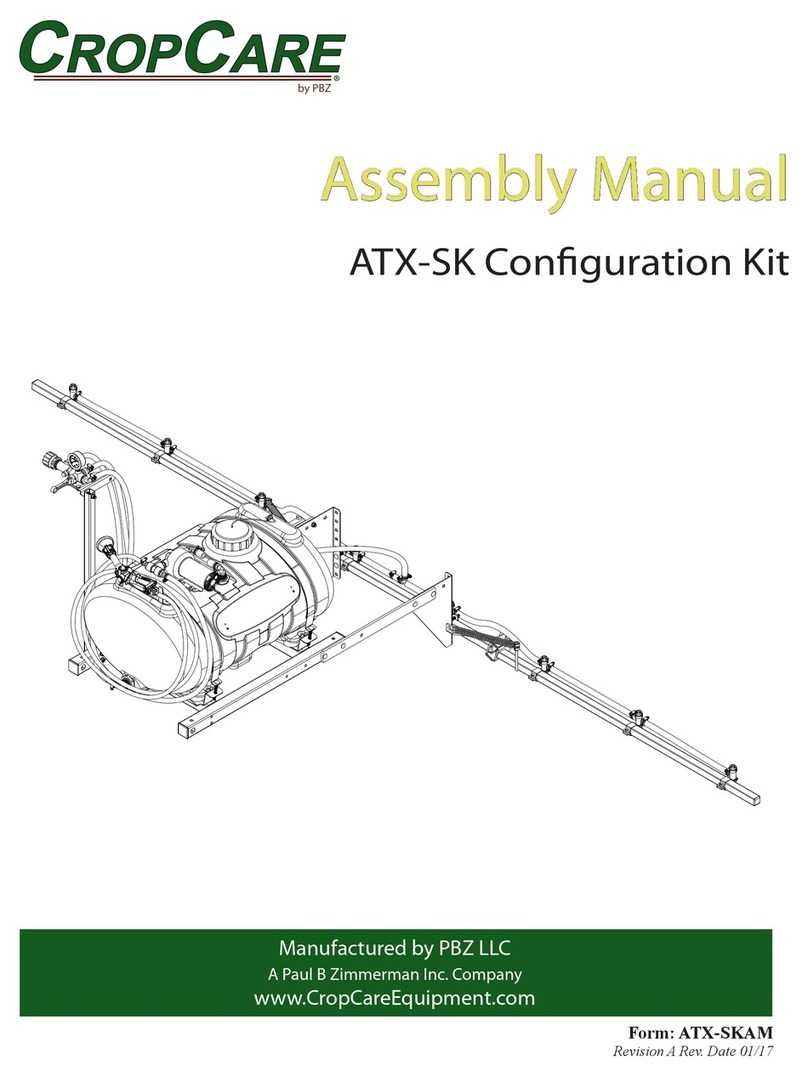

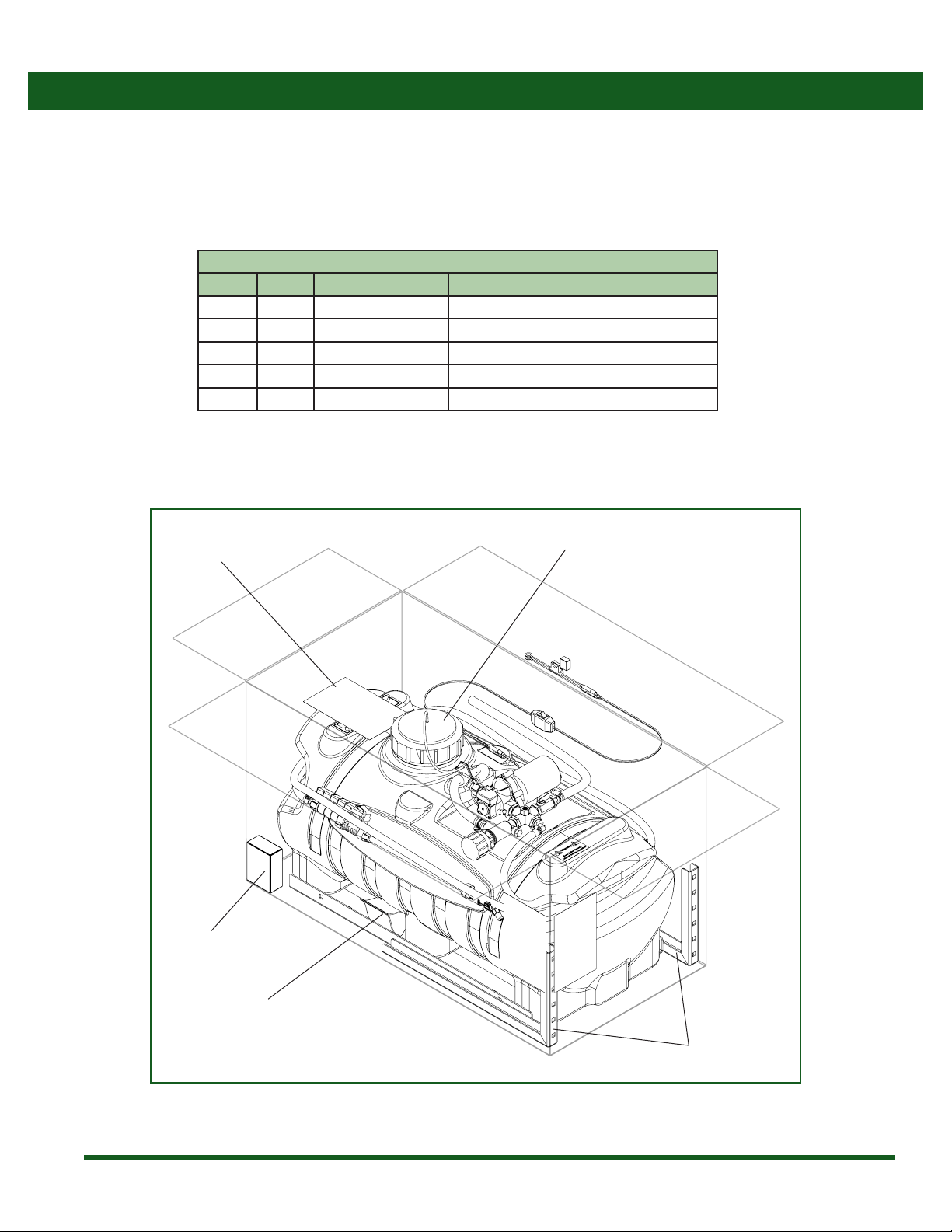

ATV-BASE Kit Contents ........................................................................... 6

ATV-BASE Box.................................................................................. 6

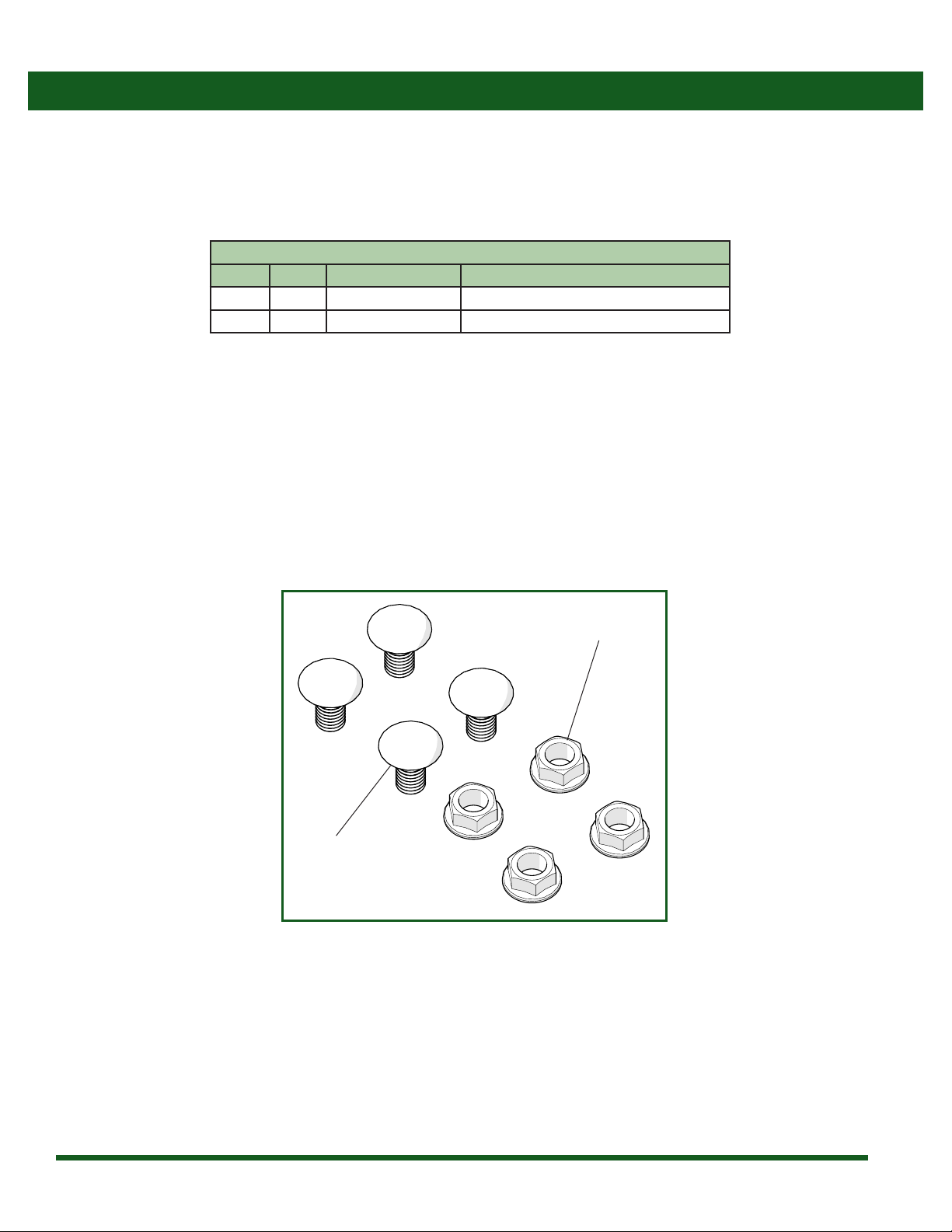

Hardware Bag ................................................................................. 7

Assembly Instructions ............................................................................ 8

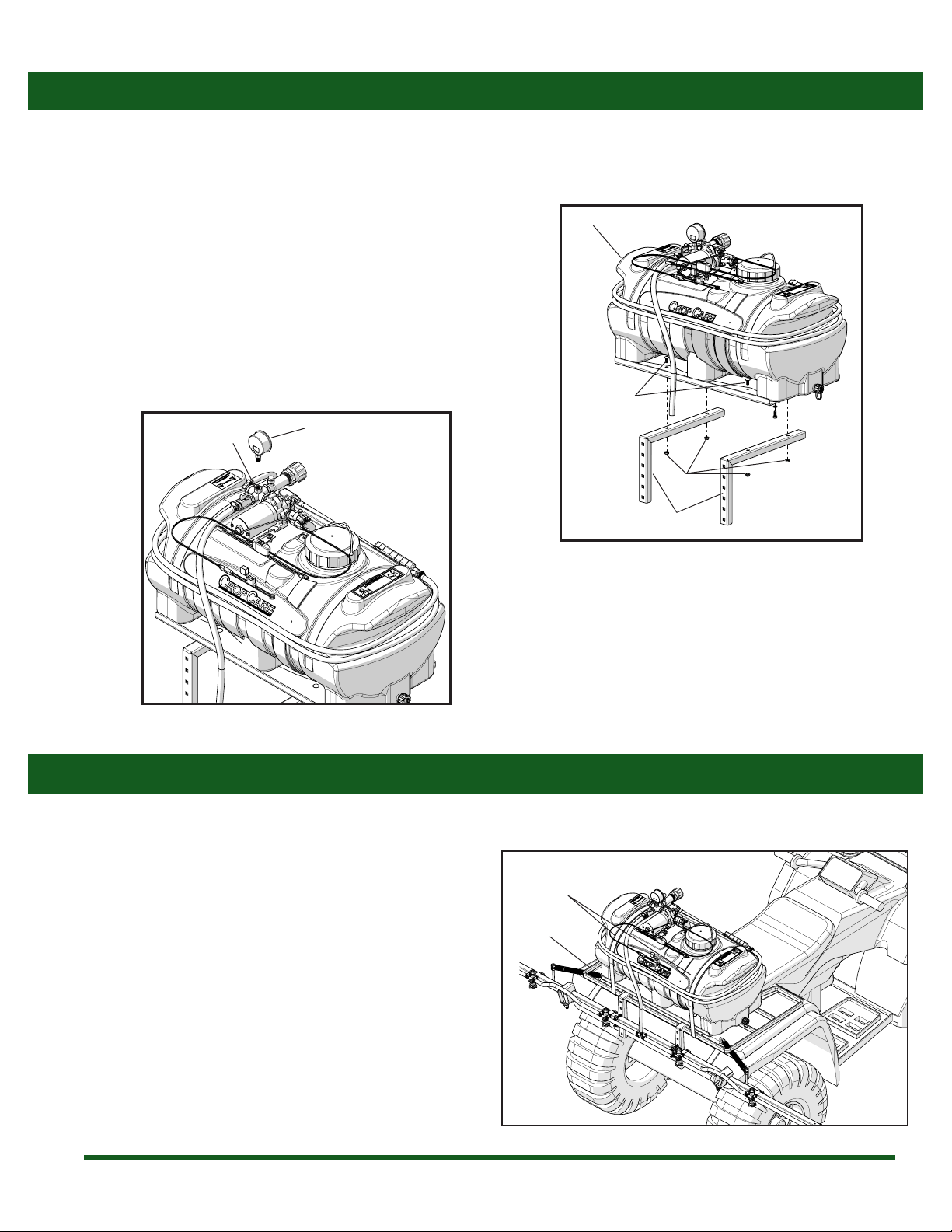

Boom Mount Bracket & Gauge Assembly............................. 8

Mounting the Sprayer............................................................................. 8

Base Unit........................................................................................... 8

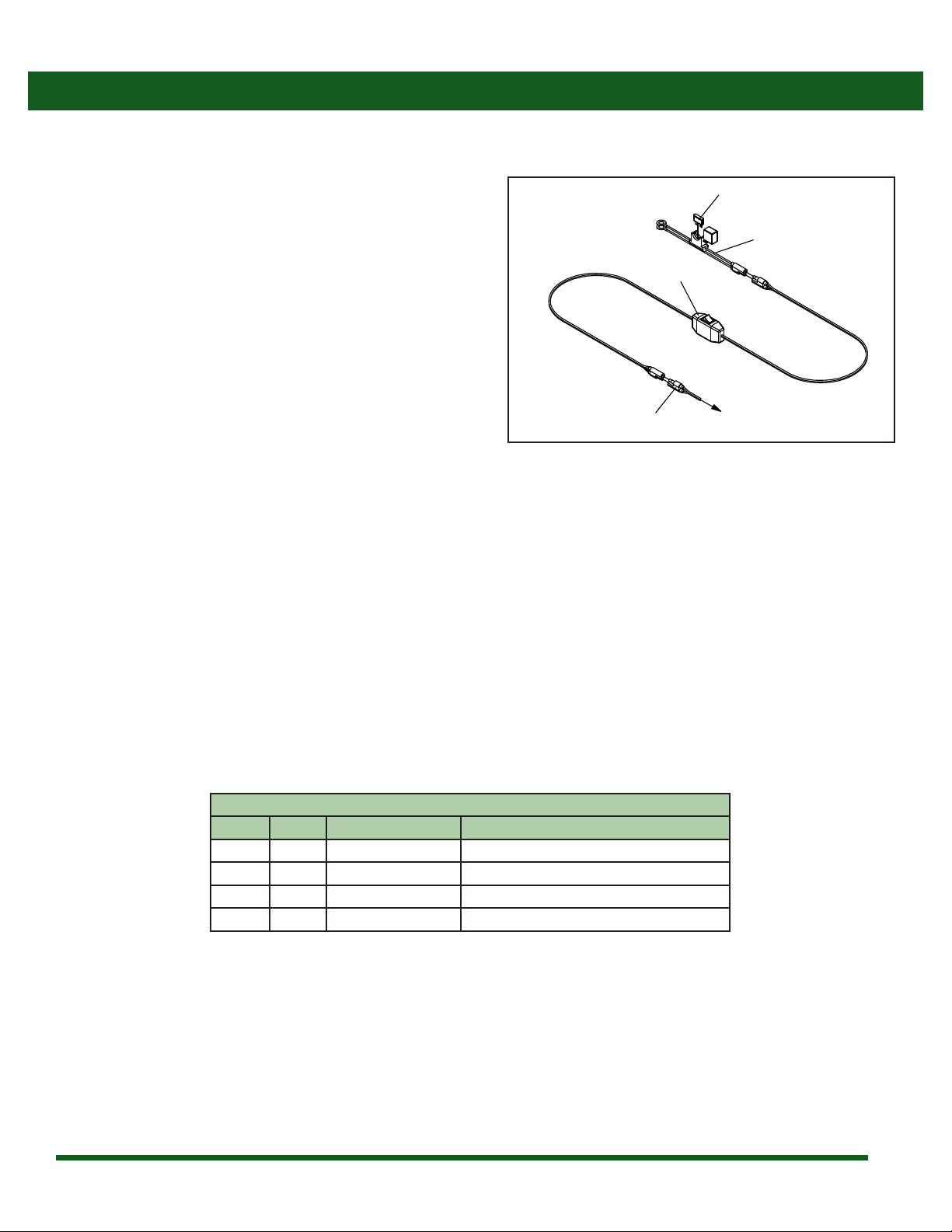

Wiring Harness ............................................................................... 9

Calibrating the Sprayer.........................................................................10

1. Calculating the Speed...........................................................10

2. Determining Nozzle Size/Using Calibrastion Chart....10

3. Adjusting the Sprayer Pressure..........................................11

Boom Calibration Chart.............................................................11

Boomless Nozzle Chart..............................................................11

Operating Instructions .........................................................................12

Spraying with the Boom ...........................................................12

Spraying with the Spray Gun ..................................................12

Following Operation ..................................................................13

Maintenance Instructions ...................................................................13

Routine Maintenance.................................................................13

Winterizing your Sprayer..........................................................14

Troubleshooting .....................................................................................14

Breakdowns and Parts Lists ................................................................15

Base Unit Breakdown.................................................................15

Base Unit Parts List......................................................................16

Shuro® Pump Breakdown & Parts List ...............................17

Relief Valve Breakdown & Parts List ......................................17

CropCare® Limited Warranty ..............................................................18

Ordering Parts .........................................................................................18

Specications

Tank capacity ................................................................................ 25 gal

Min power supply ...................................................12 volt / 10 amp

Wiring harness length ........................................................................ 8’

Pump:

Type...........................................................................Diaphragm pump

Manufacturer ............................................................................ Shuro®

Max pressure..................................................................................45 psi

Max ow rate ............................................................................... 3 gpm

Sprayer:

Spraying width (12’boom)...........................................................160”

Spraying width (20’boomless) ...................................................240”

Hose length (for handgun) .............................................................15’

25 gallon ATV sprayers

Weight:

Base unit (empty) .........................................................................44 lbs

Base unit (full)..............................................................................240 lbs

12’ boom.......................................................................................... 32 lbs

20’ boomless..................................................................................... 5 lbs

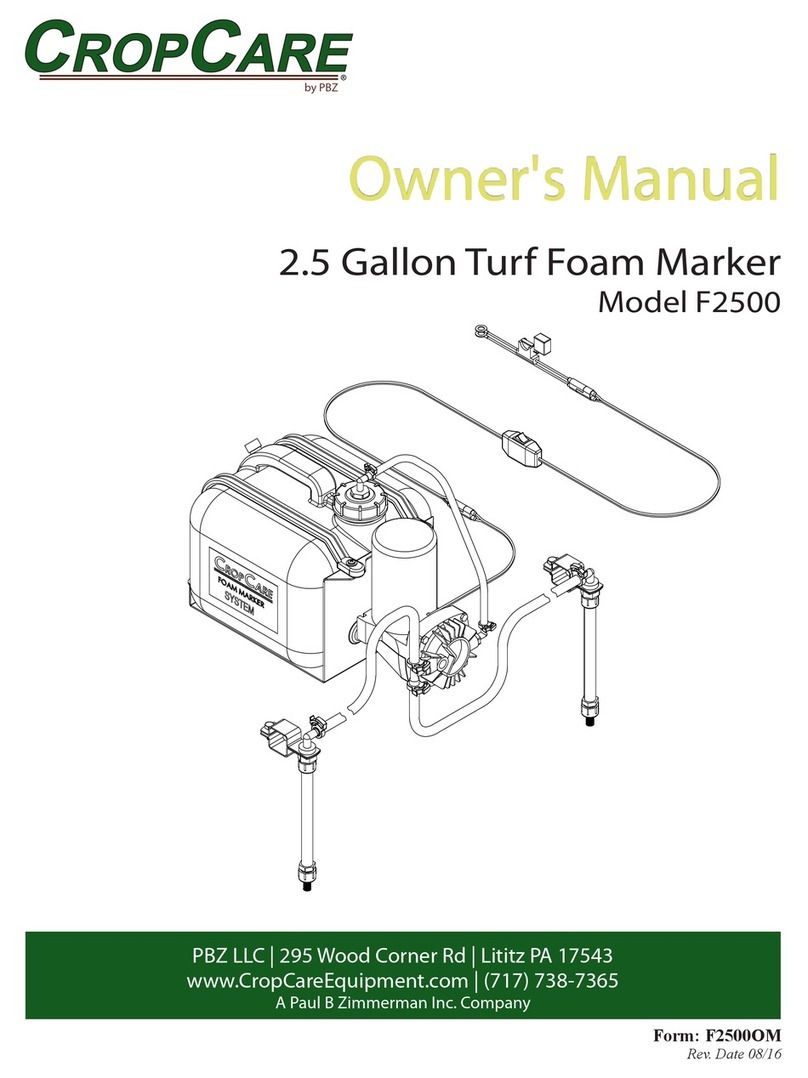

Identication of Machine

• Model #’s: ATV-BASE

• The model number and revision identication decal is located on top of the tank .