FANs 121, 125

Temperature Controls Section A

Technical Bulletin A19ZBA

Issue Date 0119

© 2019 Johnson Controls 1

Code No. LIT-121065

Part No. 997-778, Rev. A

A19ZBA Type Temperature Control

Application

The A19ZBA temperature

control is designed for water

chiller applications. The control

has a range of 38 to 80°F (3 to

27°C) with contacts that open on

a temperature drop.

A packing nut assembly, Part

No. FTG13A-600R, (Fig. 2) is

supplied with the control for

immersion applications where a

bulb well is not required. Bulb

well No. WEL14A-600R (Fig. 3)

for immersion applications is

available, if required.

All Series A19 controls are

designed for use only as

operating controls. Where an

operating control failure

would result in personal injury

and/or loss of property, it is

the responsibility of the

installer to add devices

(safety, limit controls) or

systems (alarm, supervisory

systems) that protect against,

or warn of, control failure.

Installation

When provided, follow the

equipment manufacturer’s

instructions. If instructions are

not supplied, follow the

instructions in this sheet.

CAUTION: Do not dent or

deform the sensitive bulb of

this control. A dent or

deformation will change the

calibration and cause the

control to cycle at a

temperature lower than the

dial setting.

Mounting

When installing the control, use

the mounting bracket as a

template and mark the location

for the two mounting screws.

Drill or punch two holes and start

the mounting screws. Place the

slot in the bottom of the bracket

under the head of the lower

mounting screw. Position the

control so the top screw is in the

top slot. Tighten both screws. It

is not necessary to level the

control except for appearance.

For closed tank applications

without a bulb well, use the

FTG13A-600R packing nut. (See

Fig. 2.) Put parts over the support

tube section of the element and

place bulb in the tank. Install the

1/2 in. NPT adapter in the tank

opening and tighten. Screw the

packing nut with the retaining

washers and packing into the

adapter as shown in Fig. 2.

CAUTION: Turn off the

liquid supply and relieve the

pressure before installing or

removing the bulb or bulb

well.

For applications requiring a bulb

well, install the bulb well in the

tank opening. Remove the

bushing from the bulb well and

slide the bushing over the

capillary. Insert the bulb into the

bulb well and replace the bushing.

Push the bulb into position in the

bottom of the well. Tighten the set

screw in the adapter end to hold

the bulb in position.

Wiring

WARNING: Disconnect the

power supply before wiring

connections are made to

avoid possible electrical

shock or damage to the

equipment.

Make all wiring connections

using copper conductors only,

and in accordance with the

National Electrical Code and

local regulations.

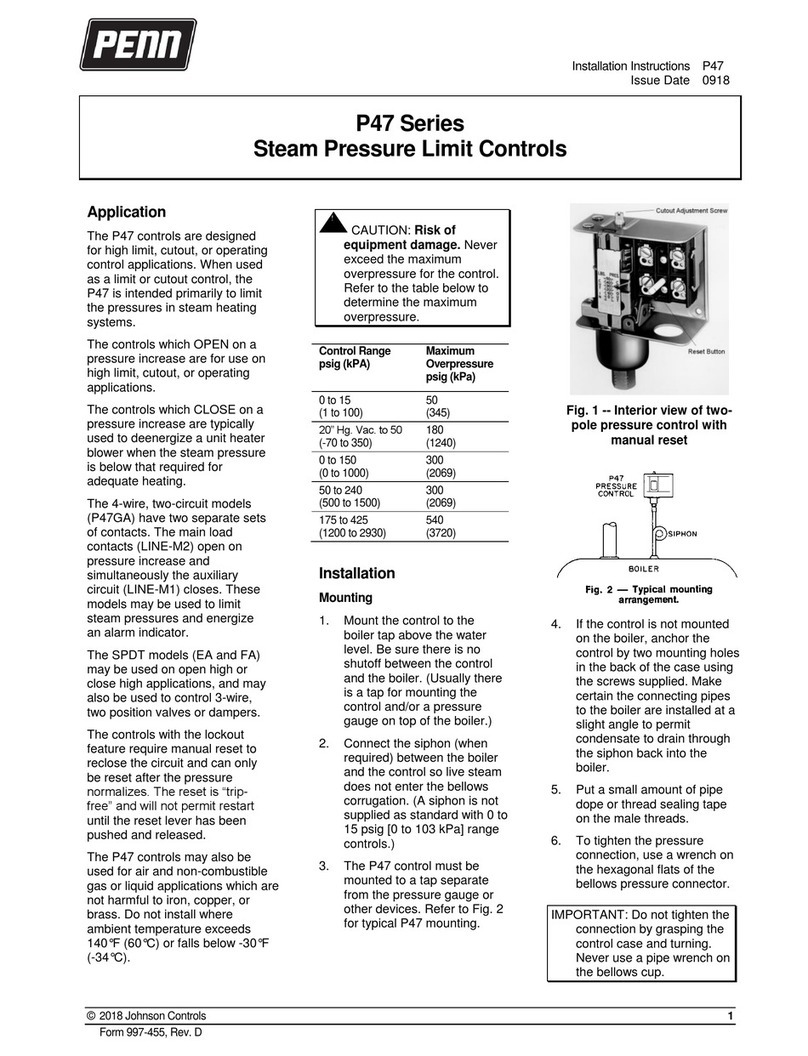

Fig. 1 -- A19ZBA-1 Temperature

Control. Note the mounting

bracket on the back of the case.

Note: Use the terminal screws

furnished (8-32 ×1/4 in. binder

head). Substitution of other

screws may cause problems in

making proper connections.