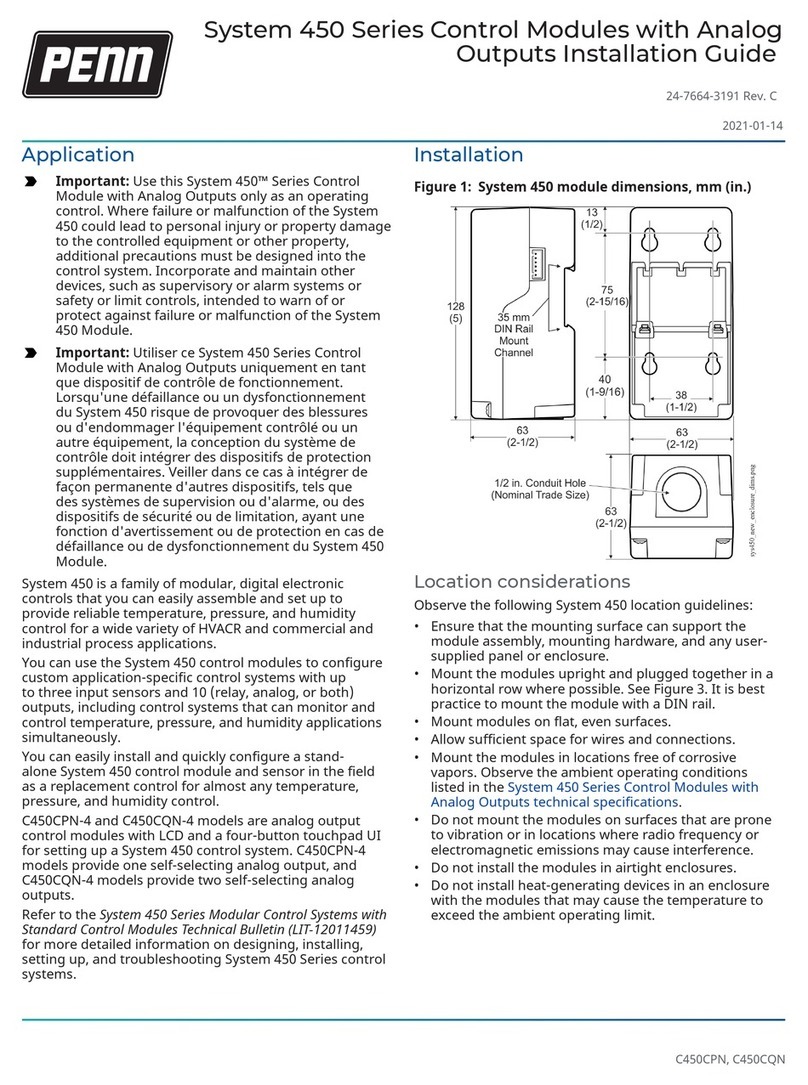

PENN | TC3B23 | Installation Guide Rev. B | Part No. 24-7664-03574 | Page 1 of 2 | 07 April 2020

TC3B23 Basic controller for refrigerated cabinets,

with energy-saving strategies

E ENGLISH

- Controller for low temperature units.

- Power supply for TC3B23N5V: 115 VAC.

- Power supply for TC3B23N7V: 230 VAC.

- Cabinet probe and auxiliary probe (NTC).

- Door switch/multi-purpose input.

- Cooling or heating operation.

1 MEASUREMENTS AND INSTALLATION

Measurements in mm (inches). To be fitted to a panel, snap-in brackets provided.

INSTALLATION PRECAUTIONS

- The thickness of the panel must be between 0.8 and 2.0 mm (1/32 and 1/16 in)

- Ensure that the working conditions are within the limits stated in the TECHNICAL

SPECIFICATIONS section.

- Do not install the device close to heat sources, equipment with a strong magnetic field,

in places subject to direct sunlight, rain, damp, excessive dust, mechanical vibrations

or shocks.

- In compliance with safety regulations, the device must be installed properly to ensure

adequate protection from contact with electrical parts. All protective parts must be

fixed in such a way as to need the aid of a tool to remove them.

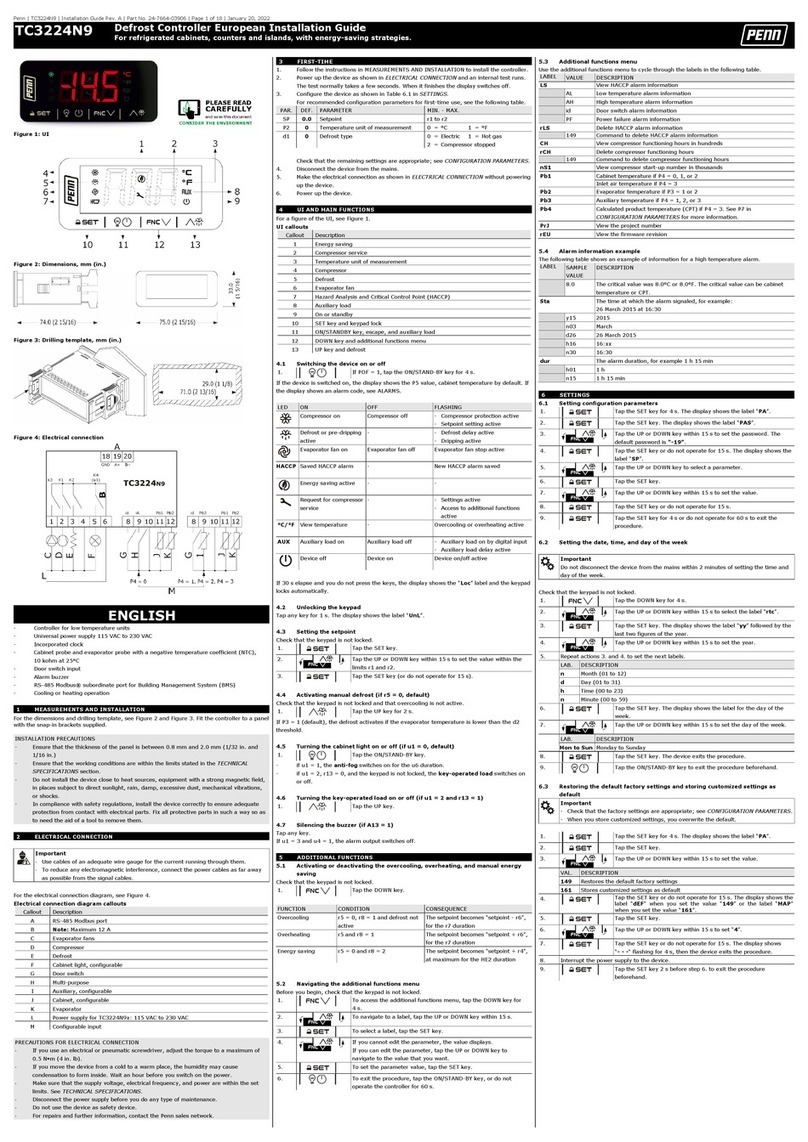

2 ELECTRICAL CONNECTION

Important

- Use cables of an adequate wire gauge for the current running through them.

- To reduce any electromagnetic interference connect the power cables as far away

as possible from the signal cables.

-Power supply for TC3B23N5V: 115 VAC.

- Power supply for TC3B23N7V: 230 VAC.

PRECAUTIONS FOR ELECTRICAL CONNECTION

- If you use an electrical or pneumatic screwdriver, adjust the torque to a maximum of

0.5 N•m (4 in. lb).

- If the device was moved from a cold to a warm place, the humidity may have caused

condensation to form inside. Wait about an hour before switching on the power.

- Make sure that the supply voltage, electrical frequency and power are within the set

limits. See the section TECHNICAL SPECIFICATIONS.

- Disconnect the power supply before doing any type of maintenance.

- Do not use the device as safety device.

- For repairs and for further information, contact the PENN sales network.

3 FIRST-TIME

1. Install following the instructions given in the section MEASUREMENTS AND INSTALLA-

TION.

2. Power up the device as shown in the section ELECTRICAL CONNECTION and an internal

test will be run.

The test normally takes a few seconds, when it is finished the display will switch off.

3. Configure the device as shown in Table 6.1 in the section SETTINGS.

Recommended configuration parameters for first-time use.

PAR. DEF. PARAMETER MIN... MAX.

SP 0.0 setpoint r1... r2

P2 0 temperature unit of measurement 0 = °C 1 = °F

d1 0 defrost type 0 = electric 1 = hot gas

2 = compressor stopped

Then check that the remaining settings are appropriate; see the section CONFIGURA-

TION PARAMETERS.

4. Disconnect the device from the mains.

5. Make the electrical connection as shown in the section ELECTRICAL CONNECTION with-

out powering up the device.

6. Power up the device.

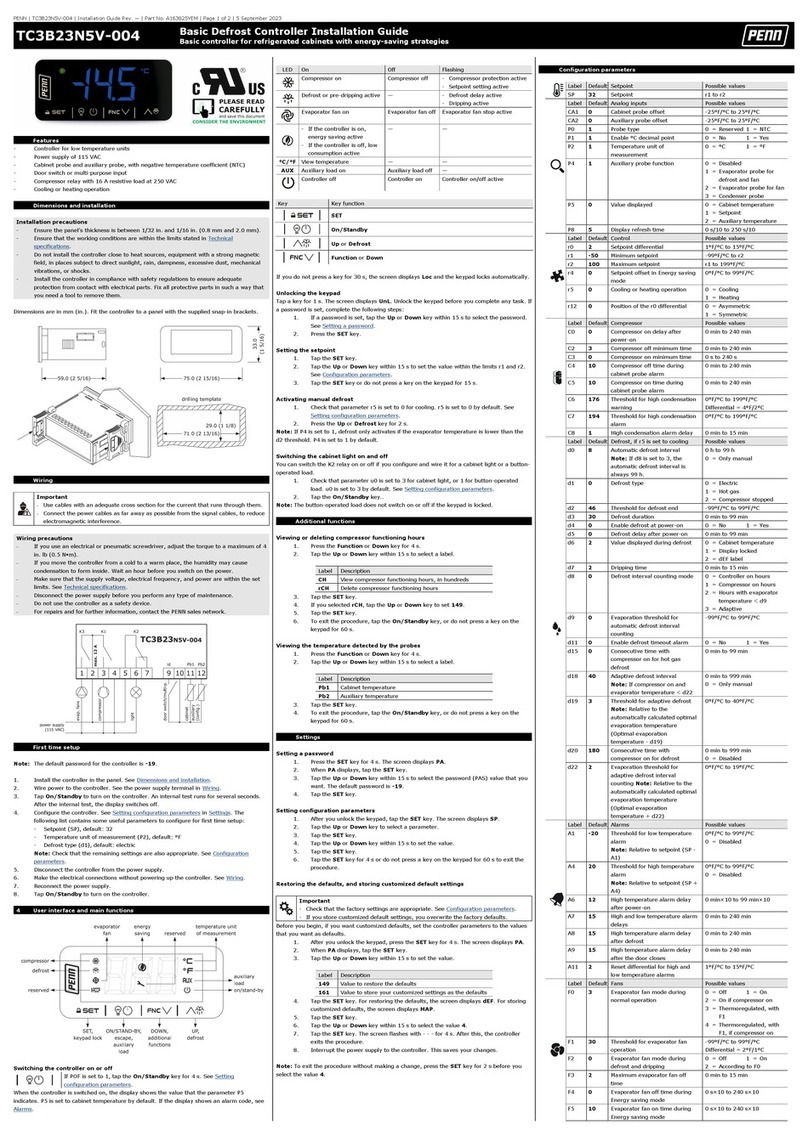

4 USER INTERFACE AND MAIN FUNCTIONS

4.1 Switching the device on/off

1. If POF = 1, touch the ON/STAND-BY key for 4 s.

If the device is switched on, the display will show the P5 value ("cabinet temperature" default);

if the display shows an alarm code, see the section ALARMS.

LED ON OFF FLASHING

compressor on compressor off - compressor protection active

- setpoint setting active

defrost or pre-dripping

active - - defrost delay active

- dripping active

evaporator fan on evaporator fan off evaporator fan stop active

-if device on, energy

saving active

- if device off, low

consumption active

- -

°C/°F view temperature - -

device off device on device on/off active

If 30 s have elapsed without the keys being pressed, the display will show the “Loc” label and

the keypad will lock automatically.

4.2 Unlock keypad

Touch any key for 1 s: the display will show the label “UnL”.

4.3 Set the setpoint

Check that the keypad is not locked.

1. Touch the SET key.

2. Touch the UP or DOWN key within 15 s to set the value within

the limits r1 and r2 (default “-40... 50”)

3. Touch the SET key (or do not operate for 15 s).

4.4 Activate manual defrost (if r5 = 0, default)

Check that the keypad is not locked.

1. Touch the UP key for 2 s.

If P4 = 1 (default), defrost is activated provided that the evaporator temperature is lower than

the d2 threshold.

5 ADDITIONAL FUNCTIONS

5.1 View/delete compressor functioning hours

Check that the keypad is not locked.

1. Touch the DOWN key for 4 s.

2. Touch the UP or DOWN key within 15 s to select a label.

LAB. DESCRIPTION

CH view compressor functioning hours (hundreds)

rCH delete compressor functioning hours

3. Touch the SET key.

4. Touch the UP or DOWN key to set “149” (when label “rCH” is se-

lected).

5. Touch the SET key.

6. Touch the ON/STAND-BY key (or do not operate for 60 s) to exit

the procedure.

5.2 View the temperature detected by the probes

Check that the keypad is not locked.

1. Touch the DOWN key for 4 s.

2. Touch the UP or DOWN key within 15 s to select a label.

LAB. DESCRIPTION

Pb1 cabinet temperature

Pb2 auxiliary temperature

3. Touch the SET key.

4. Touch the ON/STAND-BY key (or do not operate for 60 s) to exit

the procedure.

6 SETTINGS

6.1 Setting configuration parameters

1. Touch the SET key for 4 s: the display will show the label “PA”.

2. Touch the SET key.

3. Touch the UP or DOWN key within 15 s to set the PAS value (de-

fault “-19”).

4. Touch the SET key (or do not operate for 15 s): the display will

show the label “SP”.

5. Touch the UP or DOWN key to select a parameter.

6. Touch the SET key.

7. Touch the UP or DOWN key within 15 s to set the value.

8. Touch the SET key (or do not operate for 15 s).

9. Touch the SET key for 4 s (or do not operate for 60 s) to exit the

procedure.

6.2 Restore the factory settings (default) and store customized settings as default

Important

- Check that the factory settings are appropriate; see the section CONFIGURATION

PARAMETERS.

- When you store customized settings, you overwrite the default.

1. Touch the SET key for 4 s: the display will show the label “PA”.

2. Touch the SET key.

3. Touch the UP or DOWN key within 15 s to set the value.

VAL. DESCRIPTION

149 value to restore the factory settings (default)

161 value to store customized settings as default

4. Touch the SET key (or do not operate for 15 s): the display will

show the label “dEF” (when value “149” is set) or the label

“MAP” (when value “161” is set).

5. Touch the SET key.

6. Touch the UP or DOWN key within 15 s to set “4”.

7. Touch the SET key (or do not operate for 15 s): the display will

show for 4 s “- - -“ flashing, then the device will exit the proce-

dure.

8. Interrupt the power supply to the device.

9. Touch the SET key 2 s before action 6. to exit the procedure be-

forehand.

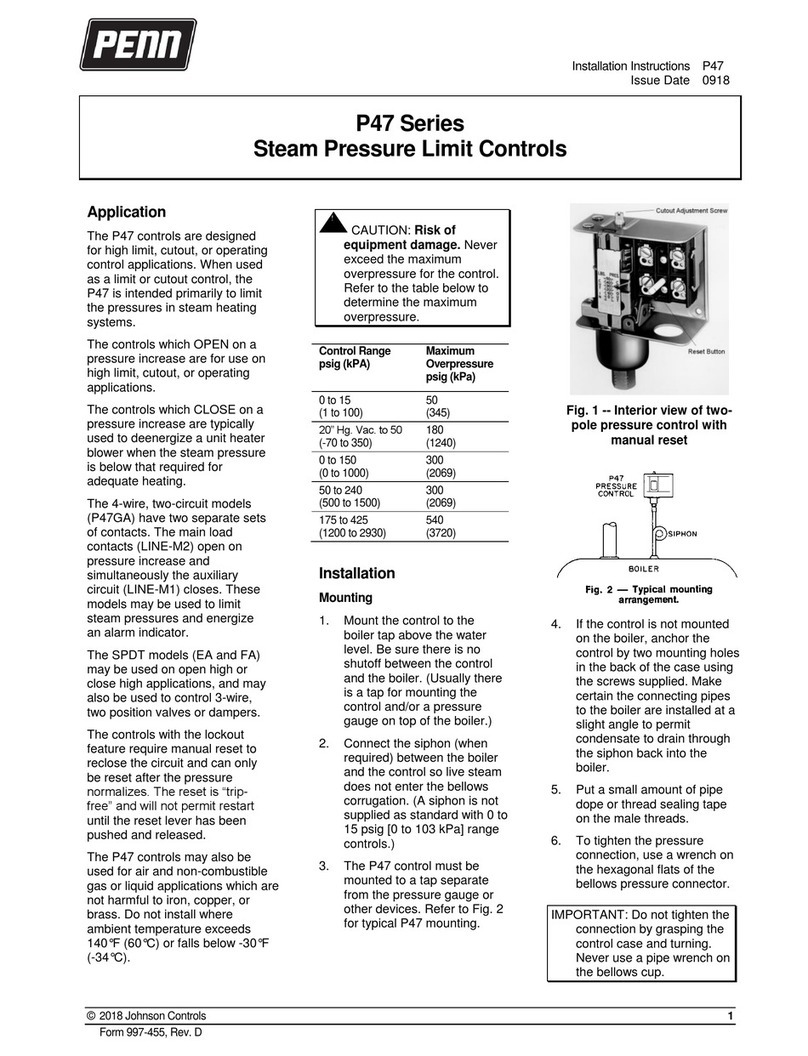

7 CONFIGURATION PARAMETERS

N. PAR. DEF. SETPOINT MIN... MAX.

1 SP 0.0 setpoint r1... r2

N. PAR. DEF. ANALOG INPUTS MIN... MAX.

2 CA1 0.0 cabinet probe offset -25... 25 °F/°C

3 CA2 0.0 auxiliary probe offset -25... 25 °F/°C

4 P0 1 probe type 0 = n/a 1 = NTC

5 P1 1 enable °C decimal point 0 = no 1 = yes

6 P2 0 temperature unit of

measurement 0 = °C 1 = °F

7 P4 1 auxiliary probe function 0 = disabled

1 = evaporator probe (de-

frost + fan)

2 = evaporator probe (fan)

3 = condenser probe

8 P5 0 value displayed 0 = cabinet temperature

1 = setpoint

2 = auxiliary temperature

9 P8 5 display refresh time 0... 250 s : 10

N. PAR. DEF. CONTROL MIN... MAX.

10 r0 2.0 setpoint differential 1... 15 °F/°C

11 r1 -40 minimum setpoint -99 °F/°C... r2

12 r2 50.0 maximum setpoint r1... 199 °F/°C

13 r4 0.0 setpoint offset in energy saving 0... 99 °F/°C

14 r5 0 cooling or heating operation 0 = cooling

1 = heating

15 r12 1 position of the r0 differential 0 = asymmetric

1 = symmetric

N. PAR. DEF. COMPRESSOR MIN... MAX.

16 C0 0 compressor on delay after pow-

er-on 0... 240 min

17 C2 3 compressor off minimum time 0... 240 min

18 C3 0 compressor on minimum time 0... 240 s

19 C4 0 compressor off time during cabi-

net probe alarm 0... 240 min

20 C5 10 compressor on time during cabi-

net probe alarm 0... 240 min

21 C6 80.0 threshold for high condenser

temperature warning 0... 199 °F/°C

differential = 4 °F/2 °C

22 C7 90.0 threshold for high condenser

temperature alarm 0... 199 °F/°C

23 C8 1 high condenser temperature

alarm delay 0... 15 min

N. PAR. DEF. DEFROST (if r5 = 0) MIN... MAX.

24 d0 8 automatic defrost interval 0... 99 h

0 = only manual

if d8 = 3, maximum interval

25 d1 0 defrost type 0 = electric

1 = hot gas

2 = compressor stopped

26 d2 2.0 threshold for defrost end -99... 99 °F/°C

27 d3 30 defrost duration 0... 99 min

if P3 = 1, maximum duration

28 d4 0 enable defrost at power-on 0 = no 1 = yes

29 d5 0 defrost delay after power-on 0... 99 min

30 d6 1 value displayed during defrost 0 = cabinet temperature

1 = display locked

2 = dEF label

31 d7 2 dripping time 0... 15 min

32 d8 0 defrost interval counting mode 0 = device on hours

1 = compressor on hours

2 = hours evaporator tem-

perature < d9

3 = adaptive

33 d9 0.0 evaporation threshold for auto-

matic defrost interval counting -99... 99 °F/°C

34 d11 0 enable defrost timeout alarm 0 = no 1 = yes

35 d15 0 compressor on consecutive time

for hot gas defrost 0... 99 min

36 d18 40 adaptive defrost interval 0... 999 min

if compressor on + evapora-

tor temperature < d22

0 = only manual

37 d19 3.0 threshold for adaptive defrost

(relative to optimal evaporation

temperature)

0... 40 °F/°C

optimal evaporation tempera-

ture - d19

38 d20 180 compressor on consecutive time

for defrost 0... 999 min

0 = disabled

39 d22 2.0 evaporation threshold for adap-

tive defrost interval counting

(relative to optimal evaporation

temperature)

0... 19 °F/°C

optimal evaporation tempera-

ture + d22

N. PAR. DEF. ALARMS MIN... MAX.

40 A1 10.0 threshold for low temperature

alarm (relative to setpoint) 0... 99 °F/°C

SP - A1

0 = disabled

41 A4 10.0 threshold for high temperature

alarm (relative to setpoint) 0... 99 °F/°C

SP + A4

0 = disabled

42 A6 12 high temperature alarm delay af-

ter power-on 0... 99 min x 10

43 A7 15 high/low temperature alarms de-

lay 0... 240 min

44 A8 15 high temperature alarm delay af-

ter defrost 0... 240 min

45 A9 15 high temperature alarm delay af-

ter door closing 0... 240 min

46 A11 2.0 high/low temperature alarms re-

set differential 1... 15 °F/°C

N. PAR. DEF. FANS MIN... MAX.

47 F0 3 evaporator fan mode during

normal operation 0 = off 1 = on

2 = on if compressor on

3 = thermoregulated (with

F1)

4 = thermoregulated (with

F1) if compressor on

48 F1 -1.0 threshold for evaporator fan op-

eration -99... 99 °F/°C

differential = 2 °F/1 °C

49 F2 0 evaporator fan mode during de-

frost and dripping 0 = off 1 = on

2 = according to F0

50 F3 2 evaporator fan off maximum

time 0... 15 min

51 F4 30 evaporator fan off time during

energy saving 0... 240 s x 10

52 F5 30 evaporator fan on time during

energy saving 0... 240 s x 10