PB_P216_11 2016

3

Wiring

WARNING: Risk of electric shock.

Disconnect or isolate all power supplies before

making electrical connections. More than one

disconnect or isolation may be required to

completely de-energize equipment. Contact with components

carrying hazardous voltage can cause electric shock and may

result in severe personal injury or death.

IMPORTANT: Do not connect supply power to the P216

Series controller before finishing wiring and checking all wiring

connections. Short circuits or improperly connected wires can

result in damage to the P216 series controller and void any

warranty.

IMPORTANT: Do not exceed the P216 Series Fan Speed

Controller electrical ratings. Exceeding P216 Series controller

electrical ratings can result in permanent damage to the P216

Series controller and void any warranty.

IMPORTANT: Use copper conductors only. Make all wiring in

accordance with local, national, and regional regulations.

IMPORTANT: Electrostatic discharge can damage P216

controller components. Use proper Electrostatic Discharge

(ESD) precautions during installation and servicing to avoid

damaging P216 components.

• Ensure that the wires between the P216 Series

controller and the fan motor do not exceed 15 m.

• Wires connected to the line-voltage terminal block must

be 3.31 mm2(12 AWG) or smaller.

• Low-voltage wires must be less than 30 m.

Description

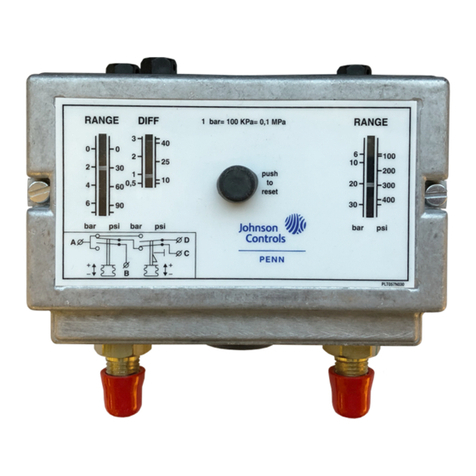

A DIP switch will be used to select one of 4 different

pressure ranges. There is one potentiometer to manually

adjust the setpoint.

• There is one potentiometer to manually adjust the

minimum speed.

• A green LED will indicate that power is applied.

• Two 3 position screw terminal blocks will be used to

connect the 50 bar transducers.

• A 3 position screw terminal block will be used to select

HP or reverse modes.

Contacts between HP and C will run the fan at full speed.

Contacts between REV and C will increase the fan speed

as pressure decreases.

• Adjustable 4 to 10 bar setpoint, prop band xed at 2.0 bar

• Adjustable 8 to 14 bar setpoint, prop band xed at 2.5 bar

• Adjustable 14 to 24 bar setpoint, prop band xed at 4.0 bar

LED

M1 L1

L2/N

L2/N

HP C REV

V P2 C

V P1 C

20% 100%

-

+

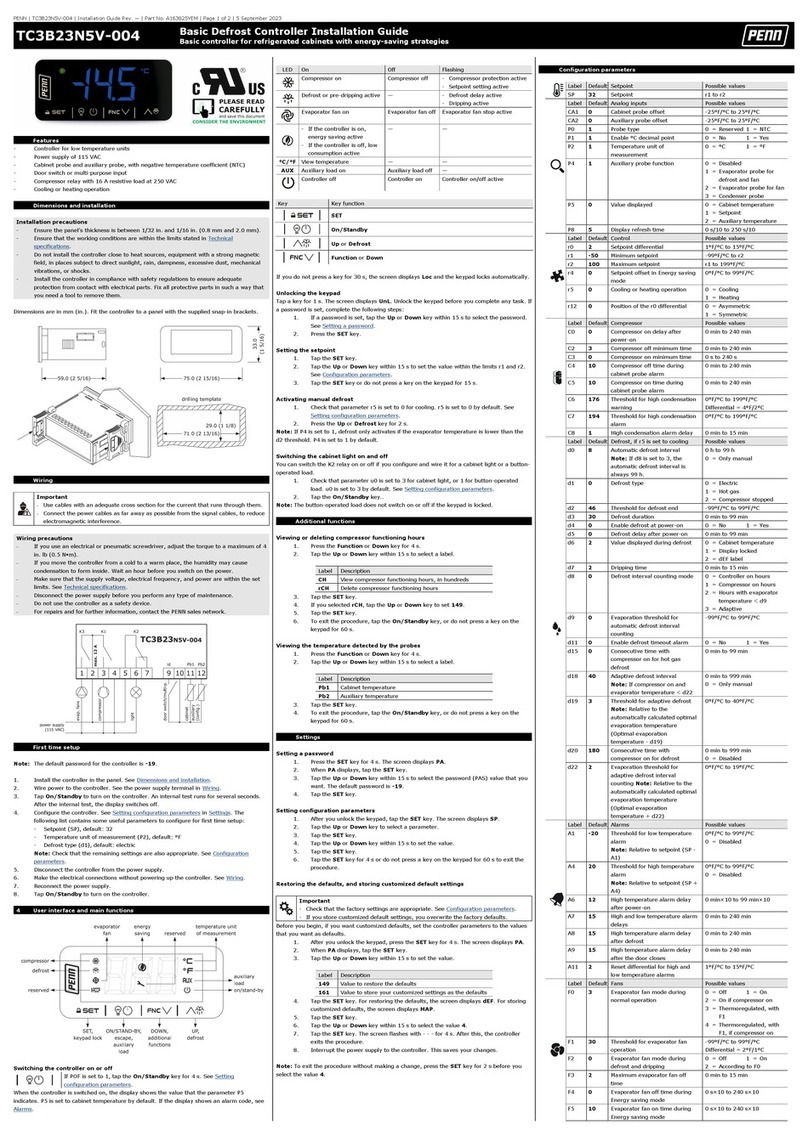

Figure 1

CAUTION

The P216 is intended to control equipment under

normal operating conditions. Where failure or

malfunction of the P216 could lead to an abnormal

operating condition that could cause personal injury or

damage to the equipment or other property, other devices

(limit or safety controls) or systems (alarm or supervisory

systems) intended to warn of or protect against failure or

malfunction of the P216 must be incorporated into and

maintained as part of the control system.

EMC

The controller does have a built-in suppression lter

and meets all required EC directives. Please note that

when two or more EMC compliant components are built

together the total system may not be compliant. To make

the total system compliant is the responsibility of the

producer.

Note:More motors can be wired in parallel, provided that

the total current will not exceed 12 A rms.

Input connections

The input can be connected as indicated in Figure 1.

If the distance between the transducer and the controller

exceeds 30 metres, shielded cable has to be used.

Heatpump

and reverse action

terminal

Power supply

and motor terminal

Earth ground

connection

Two pressure

transducers inputs

Setpoint

Min speed

DIP switch block