8

SECTION 2ITEM 1040

DATED NOVEMBER 2012

SUPERCEDES MAY 2010

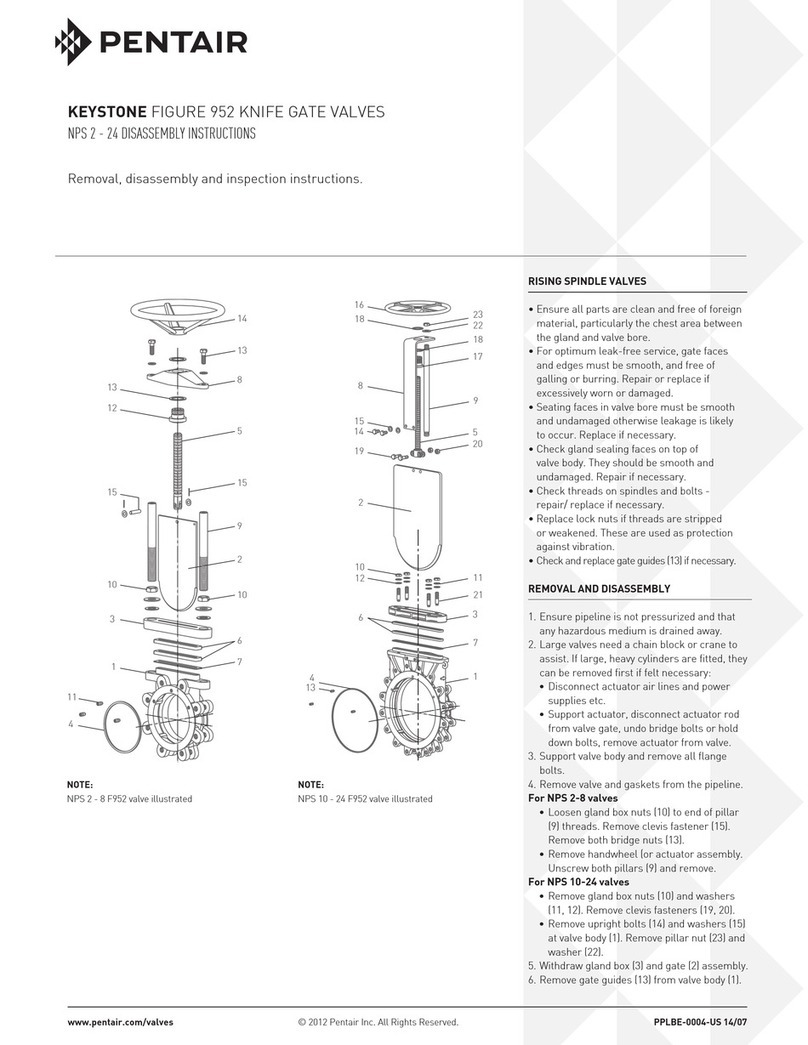

6.3.1 Record the size of the valve and stem position using the

Flow Indicator Scale (at right). Calculate percentage of

valveopeningreferringtotablebelow:

Valve

Size 21⁄23 4 5 6 8 10 12

No. of Rings

(valve full open) 5 5 6 9 10 12 18 28

6.3.2 Measure and record the differential pressure across the

valve in the throttled position.

6.3.3 Locate percentage of valve opening on the bottom scale of

FlowCharacteristic Curve (Fig 6). Projectline vertically

up to intersect with the Valve Characteristic Curve and

fromthispointprojectlinehorizontallyacrosstotheleft

ofthe chart and recordthepercentageofmaximumflow

rate.

6.3.4On the Triple Duty Performance Curve (Fig. 5) locate

the differential pressure obtained in Step 6.3.2 and

project line horizontally across to intercept with Valve

Performance Curve. Drop a line vertically down to read

theflowrateatthebottomofthechart.

6.35 To calculate flow rate of valve in the throttled position,

multiplythe flow rate fromStep 6.3.4 by thepercentage

flowratefromStep6.32dividedby100.

Example: Valve size 4 inch.

DifferentialPressureis5.4ft.(1.65m).

Number of rings open = 3. Therefore: 3 rings ÷ 6 rings x

100 = 50% throttled.

From the Triple Duty Performance Curve (Fig. 5), a 4

inchvalvewith5.4ft.pressuredrop(1.65m)representsa

flowof400USgpm(25.2l/s).

FromFlowCharacteristicCurve (Fig. 6), a 4 inch valve,

50%open,represents34%ofmaximumflow.

Approximate flow of a 4 inch valve, with a 5.4 ft. (1.65

m)pressuredropwhen50%throttledis:

400 x 34=136USgpmorinmetric25.2 x 34 = 8.57l/s

100 100

Note: To prevent premature valve failure it is not recommended

that the valve operate in the throttled position with more than

25 ft. pressure differential. Instead the pump impeller should

betrimmedorvalveslocatedelsewhereinthesystembeusedto

partiallythrottletheflow.

FLOW INDICATOR SCALE:

The valve stem with its grooved rings

and positioning sleeve indicates the

throttled position of the valve. The

quarter turn graduations on the sleeve,

with the scribed line on the stem

providesforapprox.flowmeasurement.

Note: The valve is shipped in the closed position. The

indicator on the plastic sleeve is aligned with the vertical

scribed line on the stem.

7.0 OPERATION:

7.1 To assure tight shut off the valve must be closed using a

wrenchwith25to30ft./lbs.oftorque.

7.2 Toassuretrouble-freecheckvalveoperationandshutoff

operation, the valve should be periodically opened and

closedtokeepvalveseatandvalvediscguidestemfreeof

build up of system contaminants.

8.0 REPACKING OF 3DV UNDER FULL SYSTEM

PRESSURE:

8.1 Should it be necessary, stem “O” Ring can be changed

under full system pressure. Caution: Safety glasses

shouldbeworn.

8.2 Record the valve setting.

8.3 Turn the valve stem counter-clockwise until the valve

is fully open and will not turn any further. Torque to a

maximumforceof45ft./lbs.Thiswillensuregoodmetal-

to-metalcontactandminimumleakage.

8.4 Thevalve bonnetmaynow beremoved.Theremay bea

slight leakage. As the metal-to-metal back seating does

notprovideadrip-tightseal.

8.5 Cleanexposedportionofvalvestem(Donotscratch).

8.6 Removeandreplacethe“O”Ringandgasket.

8.7 Install the valve bonnet.

8.8 Tighteningvalvebonnetisnecessarytostopanyleaks.

8.9 Open valve to balance set point as recorded in 8.2.

9.0 MAX. NUMBER OF TURNS FULL OPEN VALVE:

Note:Onvalvesizes2-1⁄2"and 3", full open position of valve

is5turns.Howevervalvewillopento5-1⁄2turnswhichisjust

backofseatingofvalve.

10.0 SEAT REPLACEMENT:

10.1 Drain system and remove valve from piping.

10.2 Remove the body bolts from the body using an Allen Key.

10.3 Remove seat and “O” Ring. “O” Ring is not used on

valves 8" and larger.

10.4 Inspect and clean “O” Ring cavity and install new “O”

Ring and seat. Valve disc stem also should be inspected

and replaced if worn. Valve stem “O” Ring should be

replaced at this time. Refer to section 8.

Inherent Flow

Characteristic Curve

with Valve in

Throttled Position

Fig. 6