Perrot P2M Operating and maintenance manual

Other Perrot Irrigation System manuals

Perrot

Perrot VP3 VAC Operating and maintenance manual

Perrot

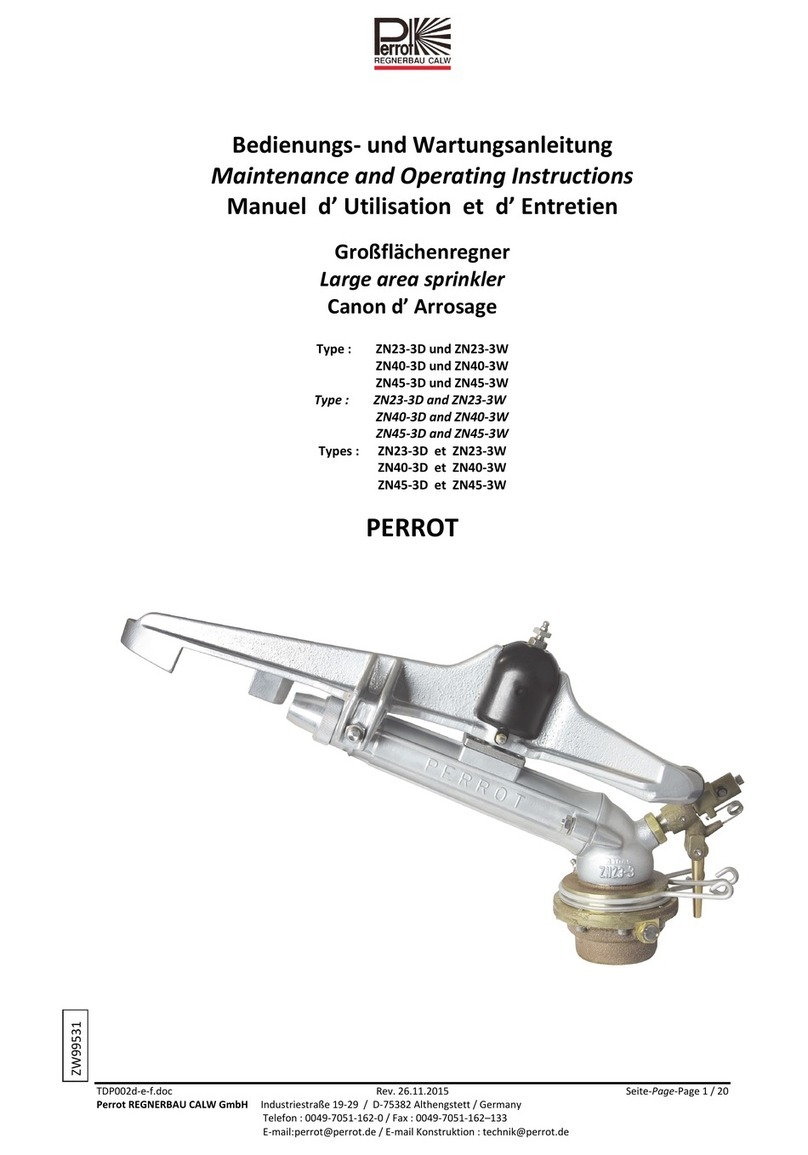

Perrot ZN23-3D Operating and maintenance manual

Perrot

Perrot VZR 22-3VDE User manual

Perrot

Perrot Hydra 2M SWVAC User manual

Perrot

Perrot ZX30 Series User manual

Perrot

Perrot VP2M User manual

Perrot

Perrot LVZE 22-1 VAC Operating and maintenance manual

Perrot

Perrot P2M Operating and maintenance manual

Perrot

Perrot RollcarT-V-2 Guide

Perrot

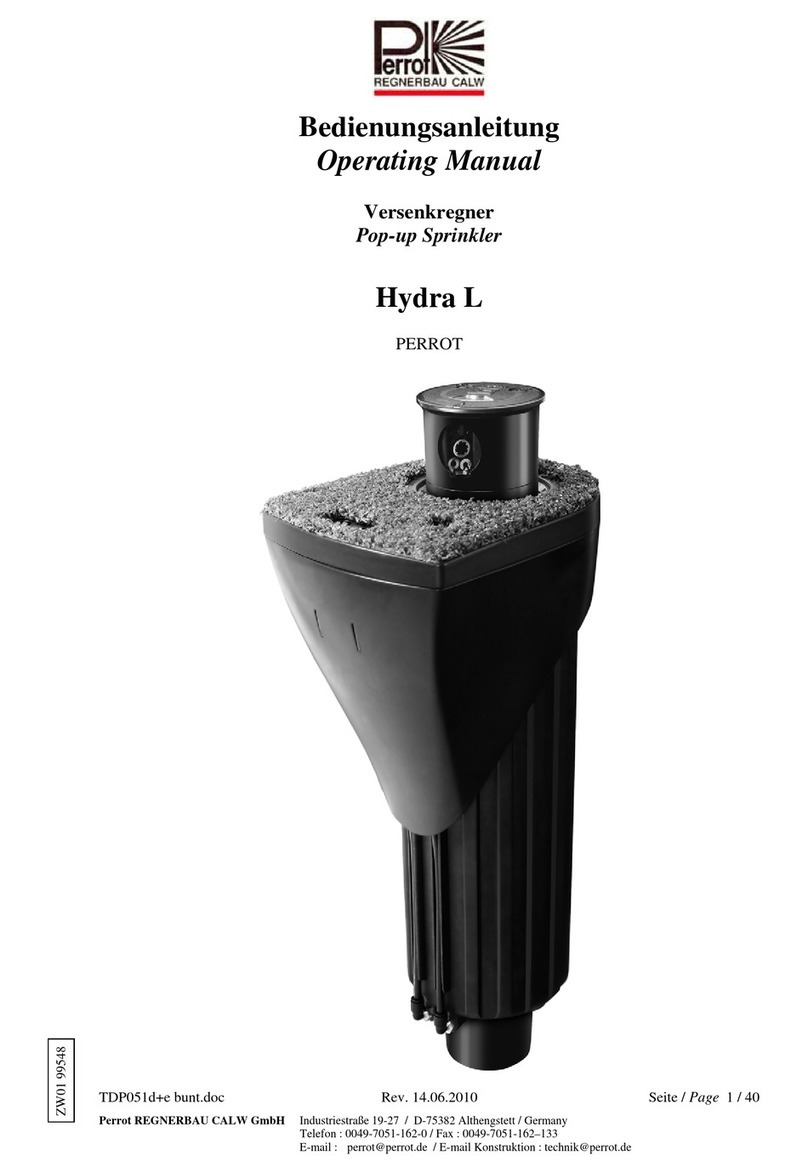

Perrot Hydra M VAC User manual

Popular Irrigation System manuals by other brands

Tyco Fire Product

Tyco Fire Product Star Galaxy SGQR instruction manual

Tyco Fire Product

Tyco Fire Product CENTRAL A instruction manual

Oral Care Technologies

Oral Care Technologies Hydro Floss Instructions for use

Reliable

Reliable F1-300 quick start guide

Tyco Fire Product

Tyco Fire Product Gem F892 instruction manual

Irrigation-Mart

Irrigation-Mart KIT-GK100-RV-B quick start guide