Perrot P2S Operating and maintenance manual

Other Perrot Irrigation System manuals

Perrot

Perrot LVZE 22-1 VAC Operating and maintenance manual

Perrot

Perrot P2M Operating and maintenance manual

Perrot

Perrot VZR 22-3VDE User manual

Perrot

Perrot P2M Operating and maintenance manual

Perrot

Perrot ZX30 Series User manual

Perrot

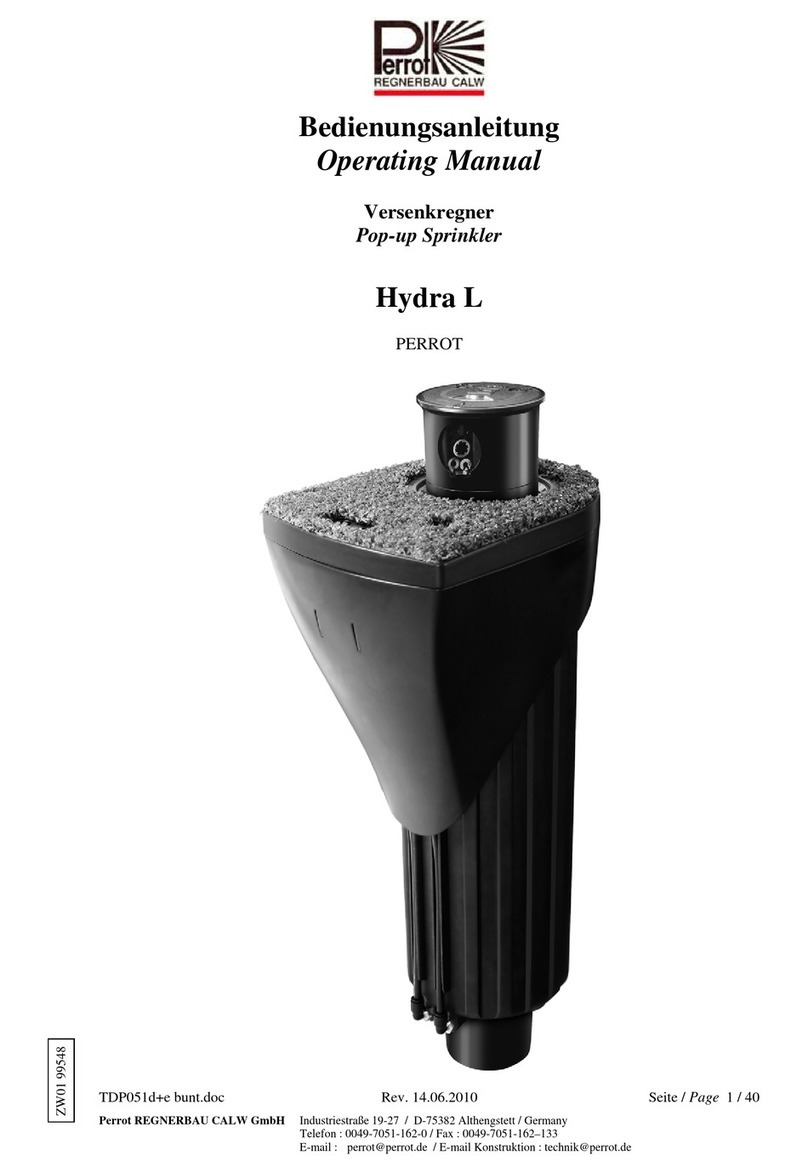

Perrot Hydra M VAC User manual

Perrot

Perrot VP2M User manual

Perrot

Perrot Hydra 2M SWVAC User manual

Perrot

Perrot VP3 VAC Operating and maintenance manual

Perrot

Perrot LVZX 30 User manual

Popular Irrigation System manuals by other brands

Tyco Fire Product

Tyco Fire Product Star Galaxy SGQR instruction manual

Tyco Fire Product

Tyco Fire Product CENTRAL A instruction manual

Oral Care Technologies

Oral Care Technologies Hydro Floss Instructions for use

Reliable

Reliable F1-300 quick start guide

Tyco Fire Product

Tyco Fire Product Gem F892 instruction manual

Irrigation-Mart

Irrigation-Mart KIT-GK100-RV-B quick start guide