MANTIS SYSTEMS 110 VOLTS

INSTRUCTIONS FOR USE AND MAINTENANCE - PLEASE UNPLUG MACHINE BEFORE SERVICING

PRODUCT DESCRIPTION

PestWest Mantis systems are made using the

highest quality materials. The bodywork is of either

conformal polyester powder-coated white or black

nish over a zintex (rust-resistant) chassis or 304

brushed stainless steel nish (Mantis 1x2 model

only). On open faced models, where the lamps

are visible when in use, there is a front chromium

plated steel guard protecting the UVA lamps against

damage as well as glue board contact.

UNPACKING YOUR System

Each system is carefully inspected and packed

before leaving our factory. Before discarding the

outer carton, examine for obvious evidence of

transport damage. Remove the system and pay

particular attention to the removal of all packing

materials including any transit packing. Including

the release paper o the glue board.

MODE OF OPERATION

The PestWest Mantis range of systems operate on

the principal that most ying insects are attracted

to light, particularly to the ultra violet (UV) end

of the light spectrum. Since insects are still very

active and will y at night, systems should be left

operating continuously, i.e.: 24 hours a day. The

Mantis systems operate by attracting ying insects

to UVA light emitted by the lamps within the system.

Do not place near lighting xtures or windows as

ying insect attraction will be reduced. Use the

Mantis systems in addition to good house-keeping

practices.

LOCATION

It is impossible to give one set of recommendations

to cover all requirements or situations. These

general guidelines are given in the knowledge that

some of them apparently conict with others. Users

should adopt those that best t their needs or seek

expert advice. As a general rule:

1. Mantis systems should be positioned so as to

minimize competition from other light sources,

so do not mount adjacent to windows. In food

areas, mount the system close to, but not

directly over, exposed food or food preparation

surfaces (preferably to attract ies away from

food preparation areas).

2. Observe where the ies tend to congregate

and if possible, put your system, in or close to

that area.

3. Position systems in an “interception” position

from the principal point of y entry - normally

doors and/or windows. In food establishments,

ies are more likely to come in through the

back door rather than the front, because that

is where the kitchen refuse and garbage cans

are kept.

4. Mount the system in a convenient location for

changing the glue board; Do not place over

working machinery where access may be

dicult or dangerous.

COVERAGE

People cannot see UVA light from UVA BL lamps,

but can see the blue light from UVA BL lamps. The

UVA light diminished over time. Additionally, UVA

light decreases proportionately by the distance

from the lamps (Inverse Square Law). Therefore, for

optimum placement and results, use the PestWest

UV-AMETER.

MAINTENANCE

To maintain the attractive appearance of the

systems, they should be cleaned/wiped down as

often as required. Use a cloth dampened with water

and detergent or a proprietary cleaner. Do not use

scouring pads or abrasives.

INSTALLATION

Select the optimum position for the system using

the guidelines given (see “Location”).

PestWest Mantis range oers a choice of either

wall-mounted or freely suspended. Wall mounted

systems are supplied with a backing plate

plastic bracket for attaching to the wall (screws

and masonry plugs supplied with the system).

Suspended systems have top lugs for tting in

suspended mode.

For safety reasons PestWest recommend that on

the suspended mounted systems, each of the

hanging chains (which are not supplied) should be

of non-corroding material that is capable of taking

at least 30 lbs each. Only welded link chains should

be used in corrosive/damp environments. For ease

of service and re-hanging, it is recommended that

the chain have a spring release clip at the end

connected to the system, ensuring that they also

are capable of supporting 30 lbs each.

The systems are tted with a 6.5 ft. power cord and

operate from a 110v 60Hz supply. If it is necessary

to extend the power cord, it is recommended that

a licensed electrician perform this work. Ensure

that once installed, the power lead is adequately

secured. Before installing any Mantis, please

remove all packaging.

This appliance must be grounded. In the event of

malfunction or breakdown, grounding provides

a path of least resistance for electric current to

reduce the risk of electric shock. This appliance

is equipped with a cord having an equipment -

grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet that

is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

The conductor with insulation having an outer

surface that is green with or without yellow stripes

is the equipment-grounding conductor. If repair or

replacement of the cord or plug is necessary, do

not connect the equipment grounding conductor

to a live terminal. Check with a licensed electrician

or serviceman if the grounding instructions are not

completely understood, or if in doubt as to whether

the appliance is properly grounded. Do not modify

the plug provided with the appliance – if it will not

t the outlet, have a proper outlet installed by a

qualied electrician.

MANTIS 1X2

The system is designed to be wall mounted, and the

wall bracket hooks under the rear lip of the lid of the

system. Using the wall bracket as a template, mark

o the two drill points on the mounting surface,

having checked that the bracket is level. Using

the screws and plastic plugs provided, secure the

bracket in place, making sure that the mounting lip

of the bracket is most elevated. Alternate securing

can be made using the keyhole slots in the back of

the system, remove the glue-board and mark the

hole position using the body as a template.

NB: If the wall is of drywall/sheet rock or stud

partition etc, suitable hardware must be used to

ensure that the system will be securely positioned.

Hook the 1x2 system onto the bracket such that the

bracket locates under the rear lip of the lid. Secure

the power cord to the wall or other rm surface prior

to connecting to the supply. Once the system is

installed, you will need to remove the backing paper

from the glue boards to reveal the glued surface.

MANTIS 2X2

NOTE: ENSURE BEFORE INSTALLING THE System

THAT THE SURFACE FROM WHICH IT IS TO BE

SUSPENDED IS CAPABLE OF SUPPORTING THE

WEIGHT.

To suspend the system, you will need two chains

of sucient length to suit (not supplied). This chain

should be of suitable gauge to support at least 30

lbs each. For ease of removal, we recommend that

the chain that is attached to the system has spring

clips at the ends for easy on/o. (again making sure

they are each capable of supporting 30 lbs each

- see - Installation). After selecting the optimum

position for the system using the guidelines given

(see - Location), attach the chains to the point from

which the system is to be suspended. Ensuring

that the system hangs level, place the clips or chain

through the suspension brackets located on either

side of the lid. Once the system is installed, you will

need to remove the backing paper from the glue

boards to reveal the glued surface.

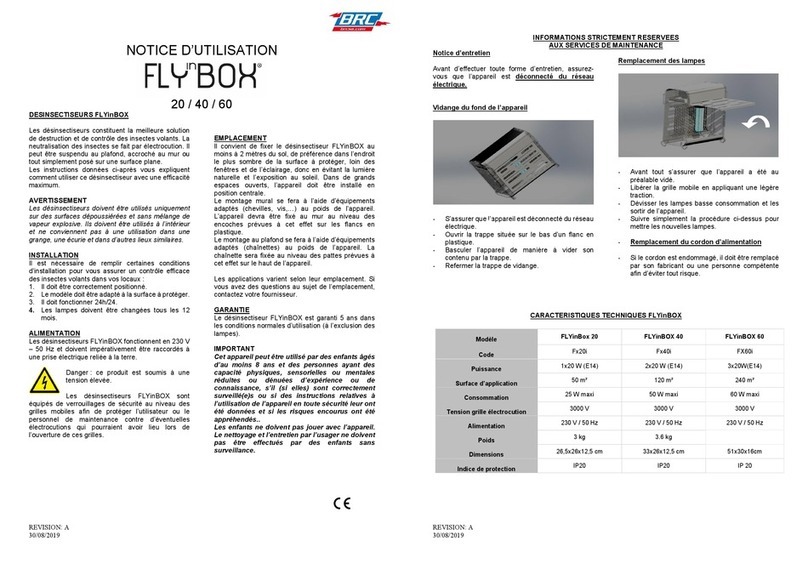

To convert the Mantis 2x2 to portable or

freestanding, see the exclusive Mantis 2x2

Freestanding Kit, sold separately.

The image below illustrates the completed kit.

Mantis 2x2

Freestanding Kit

Part Code:

822-000043

PRECAUTIONS

All PestWest systems are fully insulated, Class I

appliances, nevertheless, sensible precautions

should be observed:

• Do not install where dangerous concentrations

of ammable gases or dusts are likely to occur.

• Do not install in damp or corrosive

environments.

• Ensure the system is properly grounded.

• Avoid working on the machines while they are

still connected to the mains.