IMPORTANT SAFETY INSTRUCTIONS

WARNING – DISCONNECT FROM POWER BEFORE

OPENING FOR SERVICING

PRODUCT DESCRIPTION

This PestWest Mantis Uplight is made using the highest

quality materials. The bodywork is sprayed with

conformal polyester powder-coated nish over a zintex

(rust-resistant) steel chassis.

UNPACKING YOUR UNIT

Each unit is carefully inspected and packed before leaving

our factory. Before discarding the outer carton, examine

for obvious evidence of transport damage. Remove the

unit and pay particular attention to the removal of all

packing materials including any transit packing. Including

the release paper o the glue board.

MODE OF OPERATION

The PestWest Mantis Uplight y trap operates on the

principal that most ying insects are attracted to light,

particularly to the ultra violet (UV) end of the light

spectrum. Since insects are still very active and will y at

night, traps should be left operating continuously, i.e.: 24

hours a day.

SITING

It is impossible to give one set of recommendations

to cover all requirements or situations. These general

guidelines are given in the knowledge that some of

them apparently conict with others. Users should adopt

those that best t their needs or seek expert advice. As a

general rule:

1. Electric y traps should be positioned so as to

minimize competition from other light sources, so do

not mount adjacent to windows. In food areas, mount

the trap close to, but not directly over, exposed food

or food preparation surfaces (preferably to attract

ies away from food preparation areas).

2. Observe where the ies tend to congregate and if

possible, put your y trap, in or close to that area.

3. Position traps in an“interception”position from the

principal point of y entry - normally doors and/or

windows. In food establishments, ies are more likely

to come in through the back door rather than the

front, because that is where the kitchen refuse and

garbage cans are kept.

4. Mount the trap in a convenient location for changing

the glue board; do not place over working machinery

where access may be dicult or dangerous.

COVERAGE

Areas of attraction of ies/coverage are given in the

instructions for each unit. It should be borne in mind that

the brighter the surrounding day light, the greater the

number of units, which may be required for a given area.

MAINTENANCE

To maintain the attractive appearance of the units, they

should be cleaned/wiped down as often as required.

Use a cloth dampened with water and detergent or

a proprietary cleaner. Do not use scouring pads or

abrasives.

INSTALLATION INSTRUCTIONS

Select the optimum position for the ytrap using the

guidelines given (see“Siting”). This PestWest Mantis

Uplight has 2 keyhole slots on the rear panel, to permit

wall mounting using the screws and masonry plugs

supplied. The units are tted with a 6 foot input cable and

operate from a 110-120 volt 60Hz supply. If it is necessary

to extend the input cable, it is recommended that a

certied electrician perform this work. Should a moulded-

on plug be removed from the lead supplied, this must be

disposed of safely. Ensure that once installed, the power

lead is adequately secured. Before installing any Mantis,

please remove all packaging.

Using the unit as a template, mark o the 2 xing points

onto the mounting surface. Using the screws and plastic

plugs provided, x the Uplight body horizontally in place.

NB: If the wall is of plasterboard, stud partition etc,

suitable blind type xings must be used to ensure the unit

will be securely positioned.

Once the unit is installed, you will need to remove the

backing paper from the glue boards to reveal the glued

surface. This is most easily achieved before the glue board

is slotted into the unit.

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of

malfunction or breakdown, grounding provides a path

of least resistance for electric current to reduce the

risk of electric shock. This appliance is equipped with a

cord having an equipment -grounding conductor and

a grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

DANGER – Improper connection of the equipment-

grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer

surface that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or replacement

of the cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal. Check

with a qualied electrician or serviceman if the grounding

instructions are not completely understood, or if in doubt

as to whether the appliance is properly grounded. Do not

modify the plug provided with the appliance – if it will not

t the outlet, have a proper outlet installed by a qualied

electrician.

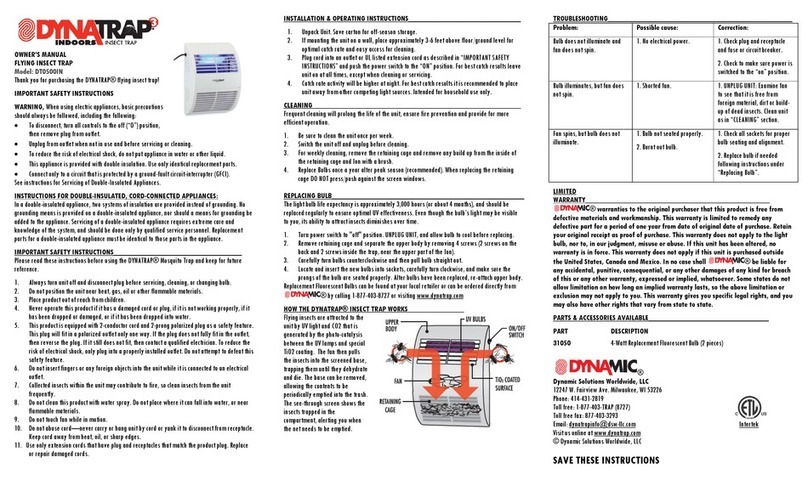

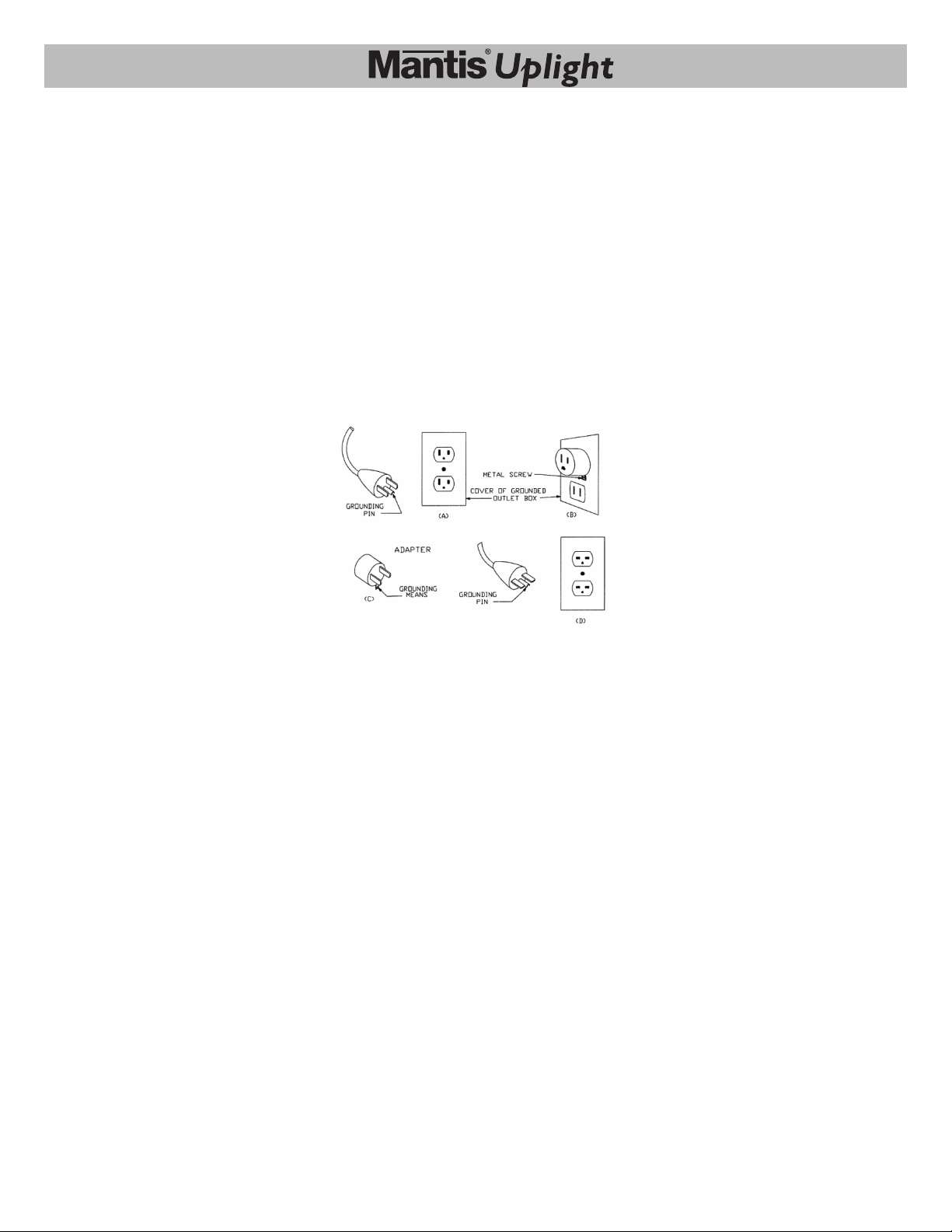

Figure 1 – Grounding Methods

This appliance is for use on a nominal 120V circuit, and has

a grounding plug that looks like the adaptor illustrated in

sketch A Figure 1. A temporary adaptor, which looks like

the adaptor illustrated in sketches B and C, may be used

to connect this plug to a 2-pole receptacle a shown in

sketch B if a properly grounded outlet is not available. The

temporary adaptor should be used only until a properly

grounded outlet can be installed by a qualied electrician.

The green colored rigid ear, lug, and the like, extending

from the adaptor must be connected to a permanent

ground such as a properly grounded outlet box cover.

Whenever the adaptor is used, it must be held in place by

the metal screw.

IMPORTANT SAFETY INSTRUCTIONS

WARNING – when using electric appliances, basic

precautions should always be followed, including the

following:

a) Read all the instructions before using the appliance.

b) Only use adaptors and attachments recommended or

sold by the manufacturer

c) Do not use outdoors.

d) To disconnect this appliance, remove plug from

outlet

e) Do not unplug by pulling on cord. To unplug, grasp

the plug, not the cord.

f) Unplug from outlet before serving for cleaning.

g) Do not operate the appliance with a damaged cord

or plug, or after the appliance malfunctions or is

dropped or damaged in any manner. Return the

appliance to the nearest authorized service facility

for examination, repair, or electrical or mechanical

adjustment.

PRECAUTIONS

All PestWest traps are fully insulated, Class I appliances,

nevertheless, sensible precautions should be observed:

• Do not install where dangerous concentrations of

ammable gases or dusts are likely to occur.

• Ensure the unit is properly grounded.

• Avoid working on the machines while they are still

connected to the mains.

• Ensure that operators have an adequate and secure

working platform when working on the machines.

• Do not allow the glue board to become over-lled

with dead insects. Change at regular intervals as

required by the catch or at least every 8 weeks.

RENEWING STICKY BOARDS

ALWAYS UNPLUG THE MACHINE BEFORE SERVICING.

Due to insect contamination the glue boards should be

changed when full or at least every eight weeks. PestWest

Mantis range all use the same size of board.

Always t PestWest glue boards to ensure peak eciency.

Remove the backing paper from the new board in a

single swift motion; otherwise it will tend to remain rmly

attached. Should this occur, re-apply the peeled back

section and repeat.

Other brands of glue boards may not have eective UV

inhibitors that PestWest brand incorporates in this system,

there fore it is recommended that ONLY PestWest brand

glue boards and suggested components be installed in

the systems.

While the recommended eight-week board replacement

cycle remains unaltered, the eective life of the glue for

a wide range of insects is enhanced. Whether you are

changing your lamps every 12 months and re-using your

shield or tting it for the rst time.

Mantis Uplight - This unit must be used with black glue

boards. Simply remove the used glue board from the

machine by pulling out of the Uplight cover. Fold the

replacement glue board slightly along its perforated line

to improve insertion into the unit and remove the backing

paper. Insert the new glue board edges under the guides

with the sticky side facing the lamps.

UV LAMP REPLACEMENT

Lamps are most attractive to the target ying insects

when less than one year. This is because the UV light

emitted by the lamps at a wavelength of 350-375

nanometres diminishes with use. Light of this wavelength

is invisible to the human eye. The blue/violet colored

light, which we can see is not at all representative of the

actual UV light emissions. Daily switching on and o of

the lamps results in an even faster loss of the eective UV

emission.

THEREFORE IT IS MOST EFFECTIVE TO LEAVE THE

UNITS SWITCHED ON CONTINUOUSLY AND TO

CHANGE THE LAMPS AT LEAST ONCE PER YEAR

(PREFERABLY AT THE ONSET OF INCREASED FLIGHT

ACTIVITY AFTER THE WINTER).

PestWest oer both standard and shatter resistant

(coated) lamps. The shatter resistant lamp is intended

for use in glass exclusion zones. The coating on

lamps supplied with our units is of the highest quality

available, using a material that is both UV and operating

temperature tolerant while allowing high emissions of the

critical (365nm) wavelength of light. Replacements should

be of similar performance.

Mantis Uplight – Grasp the lamp and rotate in either

direction (90°). After 2 clicks are heard, the lamp may be

removed by sliding out of the lamp holder. Fitting the

new lamp is a reversal of the above procedure. For optimal

performance, it is the recommendation of the lamp

manufacturer to replace the starter every time you replace

the lamp to keep fresh components in the machine at all

times.

REPLACEMENT PARTS

Quantum BL 15W X 18”T8 Standard lamp

Product code: 130-000160/TUB15W430

Quantum BL 15W X 18”T8 Shatter resistant lamp

Product code: 130-000171/TUB15W490

Classic premium black glue board

Product code: 135-000047/BOACHA850

Other alternative glue boards available, visit www.

pestwest.com

Starters: Series Starter S22

Product code: 800-000292

THIS PRODUCT IS INTENDED FOR

COMMERCIAL USE ONLY

SAVE THESE INSTRUCTIONS