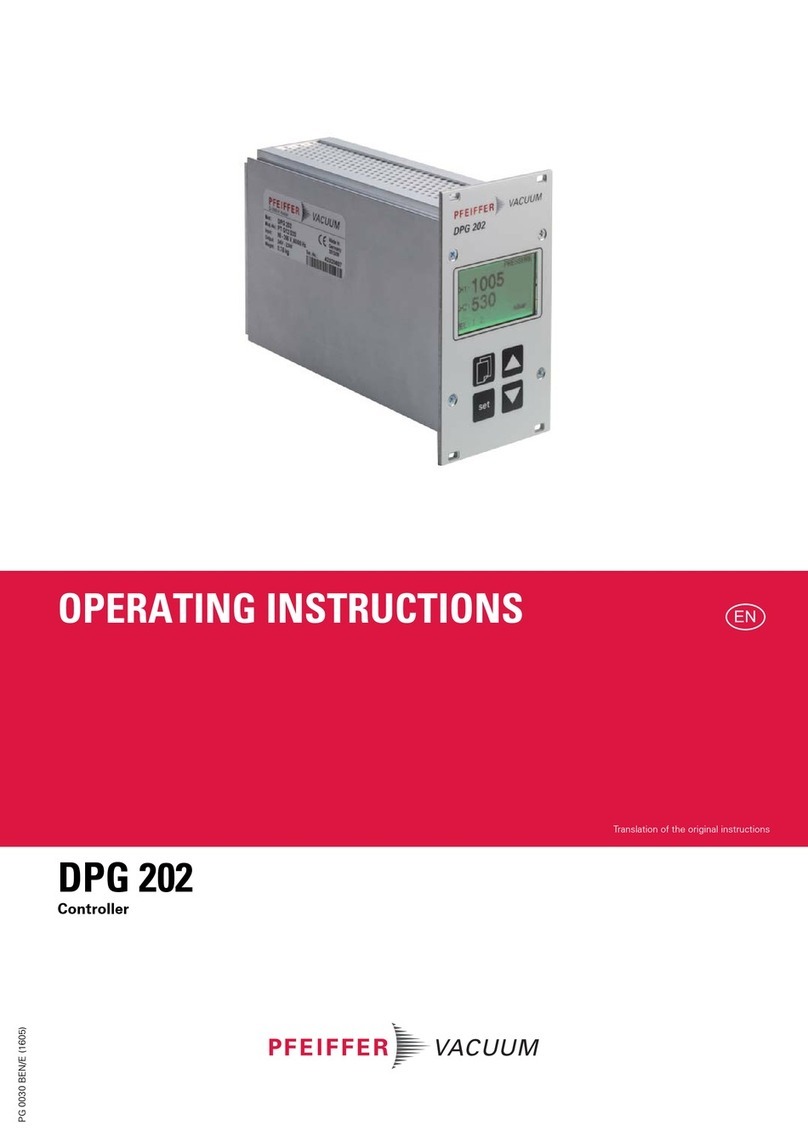

9

Connection "remote"

5 Connection "remote"

Remote control options are provided via the 26-pole D-Sub connector with the des-

ignation ”remote“ on the electronic drive unit.

Remove the remote plug from the TC 400 PB and connect a remote control unit.

Pin assignment of the connector according to table.

Shielded connectors and cables must be used.

The following information display the factory setting. Configuration is possible us-

ing the Pfeiffer Vacuum parameter set.

5.1 Pin assignment

5.2 Operation via "remote" connection

+24 V DC* Output /

Pin 1

Inputs 2 - 6 and the connections to Pins 10, 13, 14 are activated by connecting them

with +24 V DC to Pin 1 (active high). They can also be activated via an external PLC.

The functions are deactivated by "PLC high level" and by "PLC low level".

• PLC high level: +13 V to +33 V

• PLC low level: -33 V to +7 V

• Ri: 7 kΩ

•I

max

< 210 mA (with RS 485, if existing)

19

1018

1926

Pin Function Designation factory settings

1 +24 V DC output (V+) Reference voltage for all digital in- and outputs

2 DI1 Enable venting; open: no; V+: yes

3 DI Motor pump Drive motor; open: off; V+: on

4 DI Pumping station Open: off; V+: on and error acknowledgement

5 DI Standby Standby rotation speed; open: off; V+: on

6 DI2 Heating; open: off; V+: on

7 AI+ Rotation speed setting

mode

Set value in rotation speed setting mode;

2-10 V DC = 20-100% of the nominal rotation speed

8 DO1 Rotation speed switch point attained; GND:no;

V+: yes (Imax =50mA/24V)

9 DO2 GND: error; V+: no error (Imax = 50 mA/24 V)

10 DI3 Sealing gas; open: off; V+: on

11 AI- Rotation speed setting

mode GND

Set value in rotation speed setting mode; GND

12 AO1 Actual rotation speed; 0-10 V DC is equivalent to 0-100%;

RL> 10 kΩ

13 DI Error acknowledgement Error acknowledgement: V+ pulse (min 500 ms)

14 DI Remote priority Control via interface "remote"; open: off

V+: set and priority over other digital inputs

15 Relais 1 Connection to Pin 16 if relay 1 is inactive

16 Relais 1 Rotation speed switchpoint attained;

relay contact 1 (Umax = 50 V DC; Imax = 1 A)

17 Relais 1 Connection to Pin 16 if relay 1 is active

18 Relais 2 Connection to Pin 19 if relay 2 is inactive

19 Relais 2 No error; relay contact 2 (Umax = 50 V DC; Imax = 1 A)

20 Relais 2 Connection to Pin 19 if relay 2 is active

21 Relais 3 Connection to Pin 22 if relay 3 is inactive

22 Relais 3 Warning; relay contact 3 (Umax = 50 V DC; Imax = 1 A)

23 DO Remote priority GND: off; V+: remote priority active

24 RS485 D+ according to specifications and Pfeiffer Vacuum protocol

25 RS485 D- according to specifications and Pfeiffer Vacuum protocol

26 Ground (GND) Reference ground for all digital inputs and all outputs