2

1. Safety Instructions...................................................................... 3

1.1. For Your Orientation.............................................................................................4

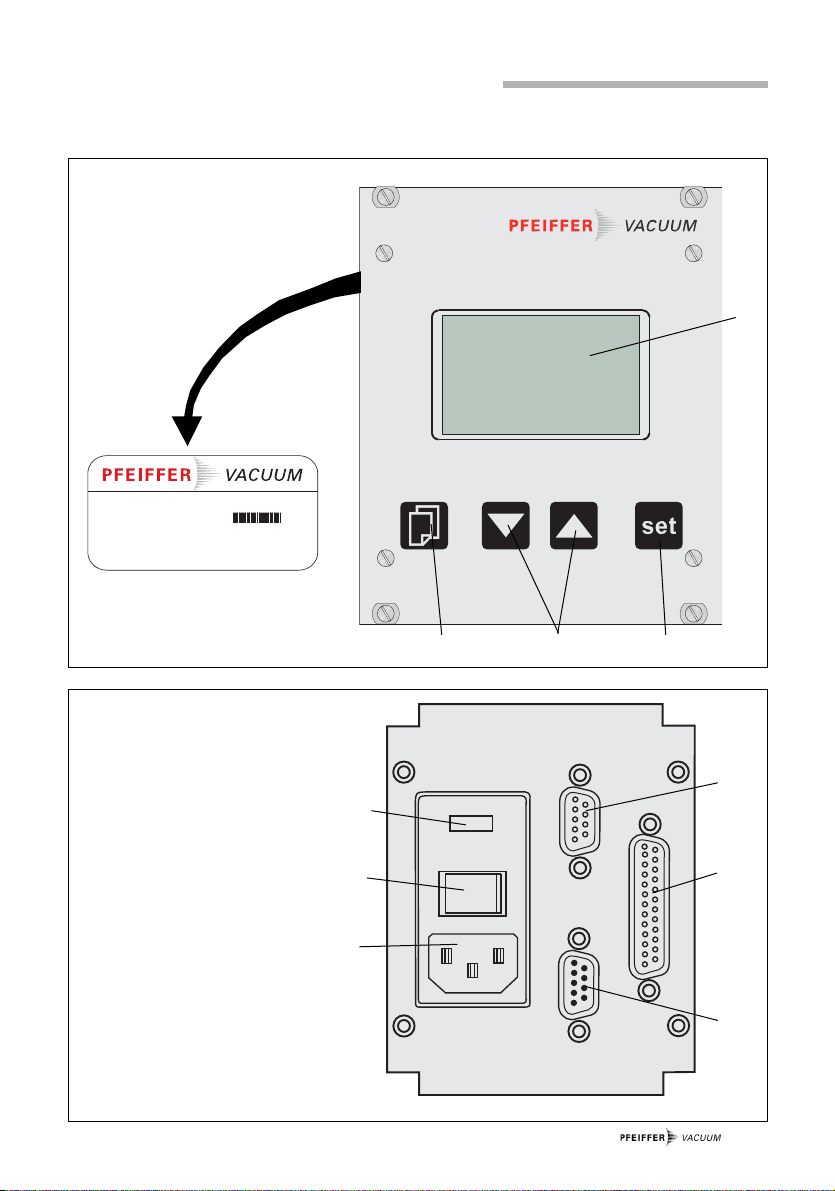

2. Understanding The DPG 109 ...................................................... 5

2.1. Main Features .....................................................................................................5

Proper Use ......................................................................................................... 6

Improper Use ..................................................................................................... 6

2.2. The Delivery Content .........................................................................................6

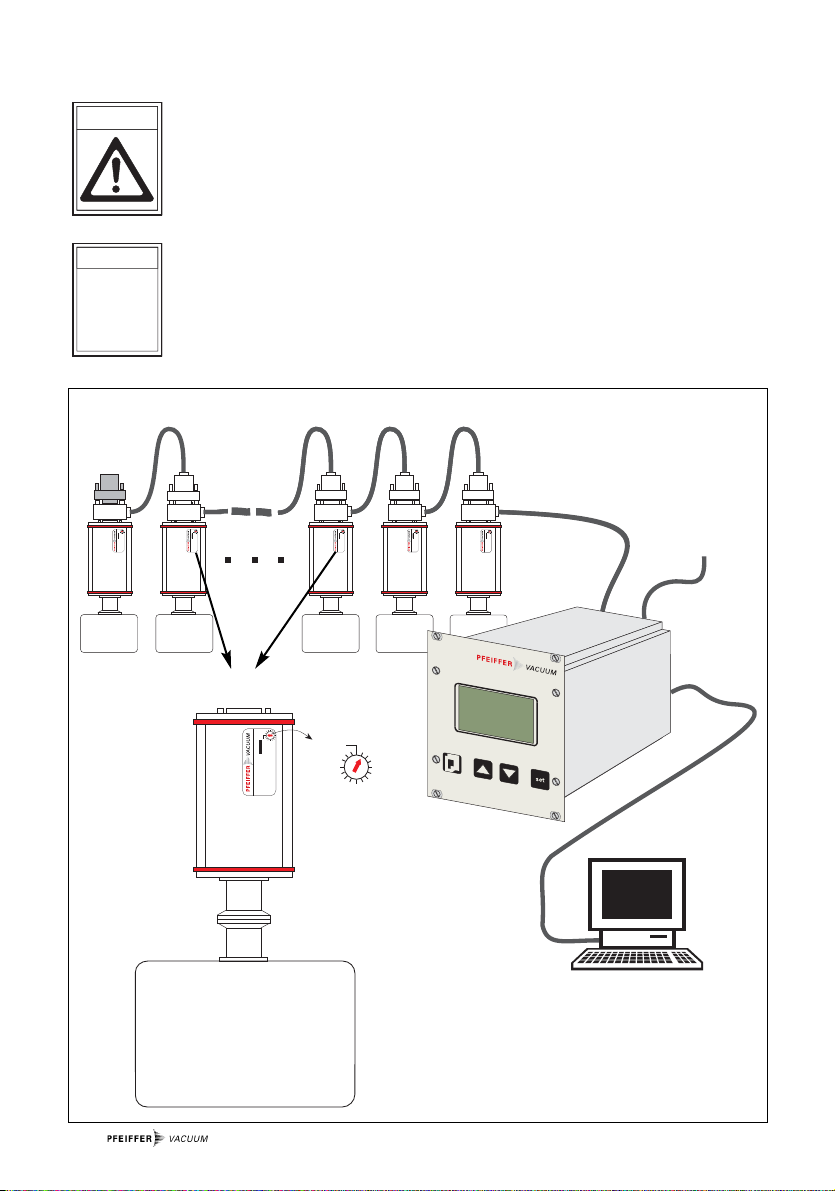

3. Installation .................................................................................. 7

3.1. Preparations For Installation............................................................................... 7

3.2. Connections ....................................................................................................... 7

3.2.1Mains Connection................................................................................................ 7

3.2.2.Transmitter Connection....................................................................................... 8

3.2.3 PC Connection (RS 232) ..................................................................................... 9

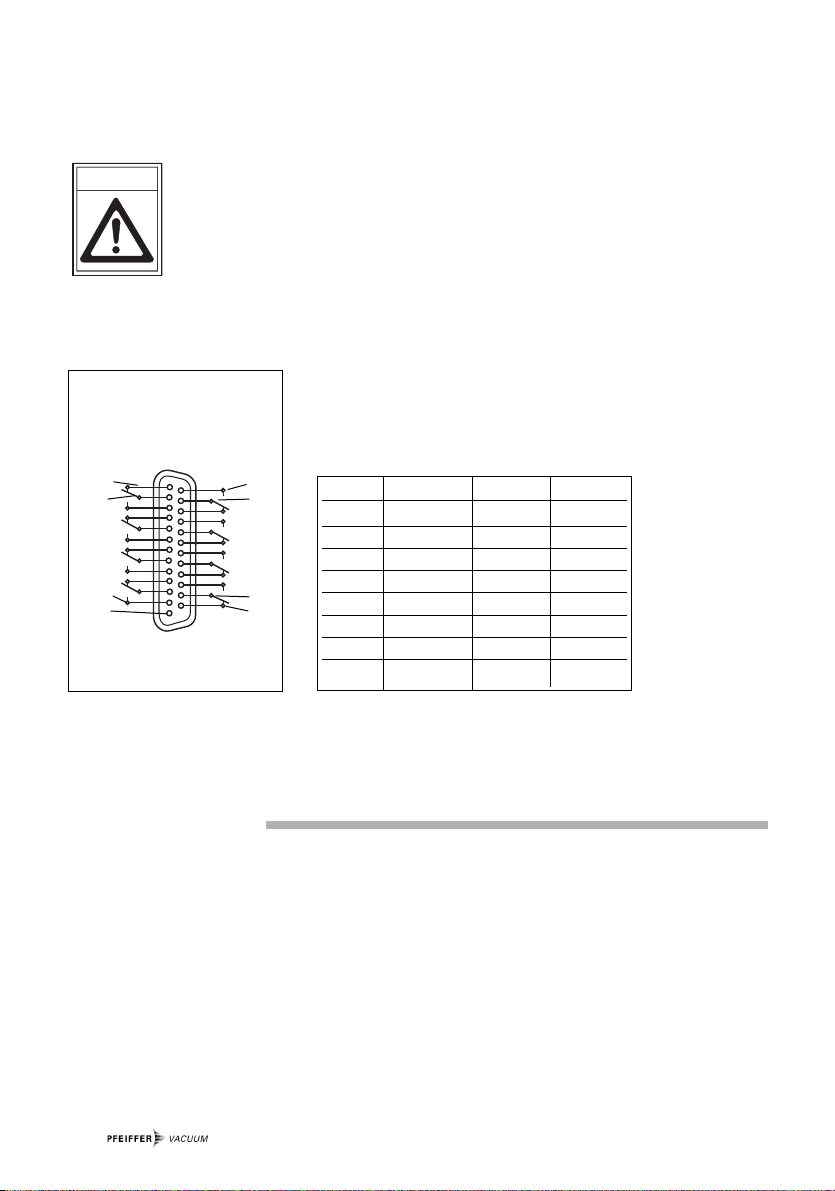

3.2.4.Relay Output ..................................................................................................... 10

4. Operations ................................................................................ 11

4.1. First-Time Operation......................................................................................... 11

4.2. Switching On The Unit.......................................................................................12

4.3. Measuring Mode.............................................................................................. 12

4.4. Configuration Mode (Overview Of Menu Options) .......................................... 12

4.5. General Procedure For Parametering ............................................................... 14

4.5.1. Menu «PRESSURE» ........................................................................................ 15

4.5.2.Menu «CHANNEL MENU»............................................................................... 17

Gas Type Correction Factor («CHANNEL MENU»)........................................... 18

Retro Adjustment («CHANNEL MENU») ......................................................... 19

4.5.3. Menu «CHANNEL MENU» .............................................................................. 20

Degassing («CHANNEL MENU»)..................................................................... 21

4.5.5 Menu «RELAY MENU» .................................................................................... 22

4.5.6.Menu «COMMON MENU» .............................................................................. 24

4.6 Communication Via RS 232 Interface............................................................... 25

5. Error Signals ............................................................................. 27

6. Maintenance, Service................................................................ 28

7. Technical Data .......................................................................... 29

7.1. Data Listings .....................................................................................................29

7.2. Dimensions Diagram........................................................................................ 29

8. Accessories ............................................................................... 30

9. Supplementary Information ..................................................... 30

Declaration Of Conformity .............................................Appendix

Index

Page

Please note

Current operating instructions are available via www.pfeiffer-vacuum.net