Pfeiffer Vacuum TPG 300 User manual

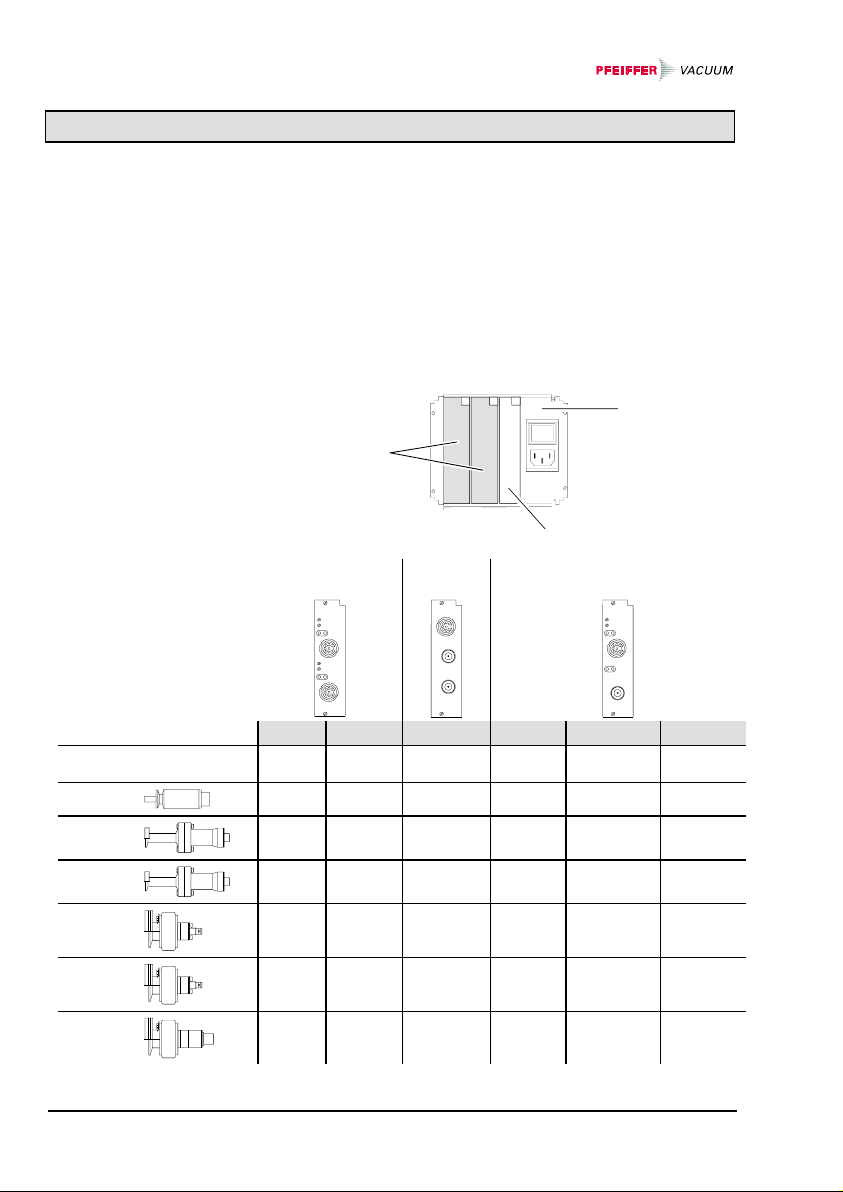

Other Pfeiffer Vacuum Controllers manuals

Pfeiffer Vacuum

Pfeiffer Vacuum TCP 600 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum TC 400 PB User manual

Pfeiffer Vacuum

Pfeiffer Vacuum MaxiGauge TPG 256 A PT G28 760 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum OPS 100 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum DPG 109 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum Tele TC cable 110 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum TCP 120 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum TCM 1601 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum DPG 202 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum TPS 110 User manual