2

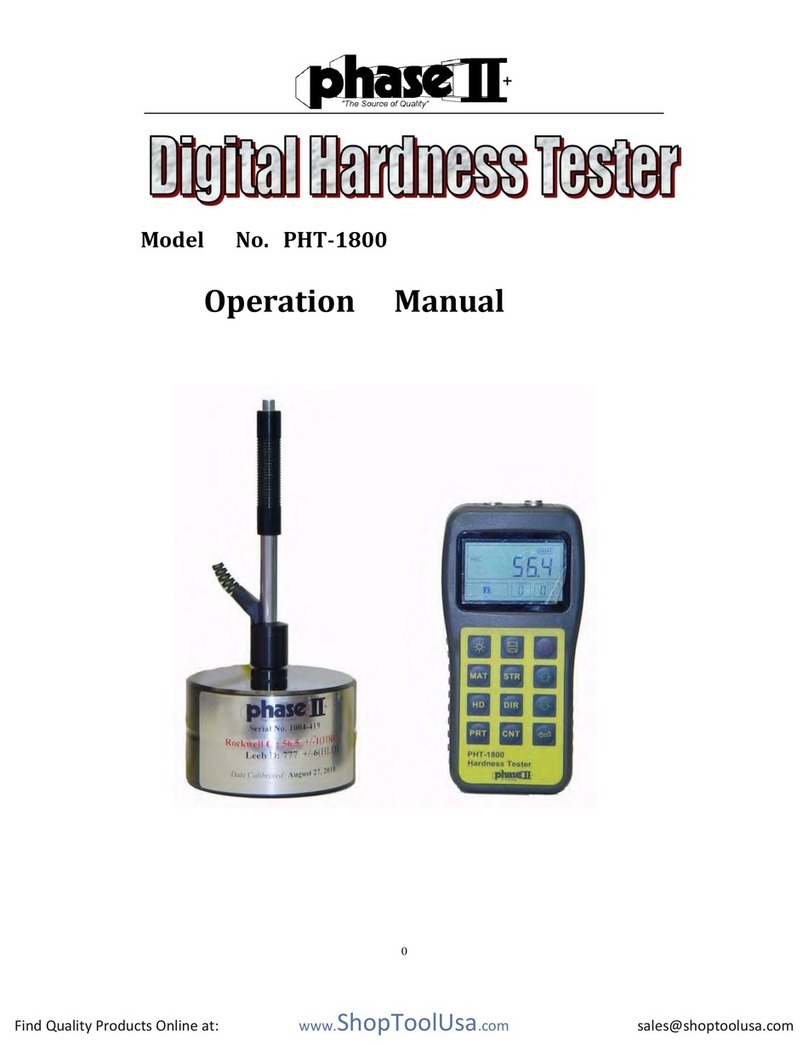

Dynamic Impact Device Type D Ultrasonic Transducer

Dynamic Testing Method information:

The Leeb measuring method was first brought into

measurement technology in 1978. It is defined as

the quotient of an impact body’s rebound velocity

over its impact velocity, multiplied by 1000.

Harder materials produce a higher rebound velocity

than softer materials. For a specific group of

material (e.g. steel, aluminum. etc.). Leeb hardness

value represents a direct relationship to its hardness

properties. For ordinary metal, conversion curves

of hardness HL versus other standard static

hardness (HB, HV, HRC, etc.) are available,

enabling you to convert HL into other hardness

values.

Leeb Hardness Test (definition)

An impact body with a spherical test tip made of

tungsten carbide is propelled against the sample

surface by a spring force and then rebounds back.

At a distance of 1mm from the sample surface, the

impact and rebound velocity of the impact body are

measured by the following method: A permanent

magnet embedded in the impact body, when

passing through the coil in its coil holder, induces

in the coil an electric voltage proportional to the

velocities of the magnet. Leeb hardness is

expressed by the following formula:

HL = 1000 x (VB/VA)

Where: HL is Leeb Hardness

VB is the rebound velocity of the impact body

VAis the impact velocity of the impact body

Ultrasonic Testing (UCI)Method information:

UCI method Ultrasonic Contact

Impedance, a hardness testing method

developed by Dr. Claus Kleesattel in

1961 based on the measurement of the

frequency shift of a resonating rod caused

by the essentially elastic nature of a of

the finite area of contact between the

indenter and the test piece during the

penetration.

In the mobile hardness test under applied

load according to the UCI method, the

size of the produced indents are not

determined optically. Instead the contact

area is derived from the electronically

measured shift of an ultrasonic resonance

frequency. To carry out the UCI test, a

probe containing the rod with the

indenter is excited into a longitudinal

ultrasonic oscillation of about 70 kHz by

piezo-electric ceramics- the so called

zero frequency, which occurs when the

indenter is vibrating in air. A spring

inside the probe applies the specified test

load, the vibrating tip penetrates into the

material creating an elastic contact,

which results in a positive frequency shift

of the resonating rod. This shift is related

to the size of the indent area. The size, in

turn, is a measure for hardness of the test

material at a given modulus of elasticity.