2

Find Quality Products Online at: www.ShopToolUsa.com sales@shoptoolusa.com

4.3 Localization ....................................................................................................................

11

4.4 Testing .............................................................................................................................

11

4.5 Read Measured Value .....................................................................................................

12

4.6 Notification .....................................................................................................................

12

5 Operation Detail .....................................................................................................

12 5.1 Power On/Off ..................................................................................................................

12

5.2 Material Setting ..............................................................................................................

13 5.3 Hardness/Strength testing

............................................................................................... 14 5.4 Impact Direction

Setting ................................................................................................. 14

5.5 Average Times Setting ....................................................................................................

14

5.6 Data logging ....................................................................................................................

14

5.2.1 Viewing stored file/Group ............................................................................................

14

5.2.2 Clearing selected file/Group ........................................................................................

15

5.7 Print Report

..................................................................................................................... 15

5.8 System Reset

................................................................................................................... 16

5.9 EL Backlight

................................................................................................................... 16

5.10Auto Power Off

............................................................................................................. 16

5.11Battery Replacement

..................................................................................................... 16

5.12Connecting to a Computer

............................................................................................ 16

5.13Error Code Reference

................................................................................................... 16 6 Maintenance &

Servicing ...................................................................................... 17

6.1 Impact Device Maintenance ...........................................................................................

17

6.2 Instrument Maintenance Program ...................................................................................

17 6.3 Fault Analysis & Evaluation

........................................................................................... 17

6.4 Notice ofTransport and Storage Conditions ................... Error! Bookmark not defined.

APPENDIX .................................................................................................................

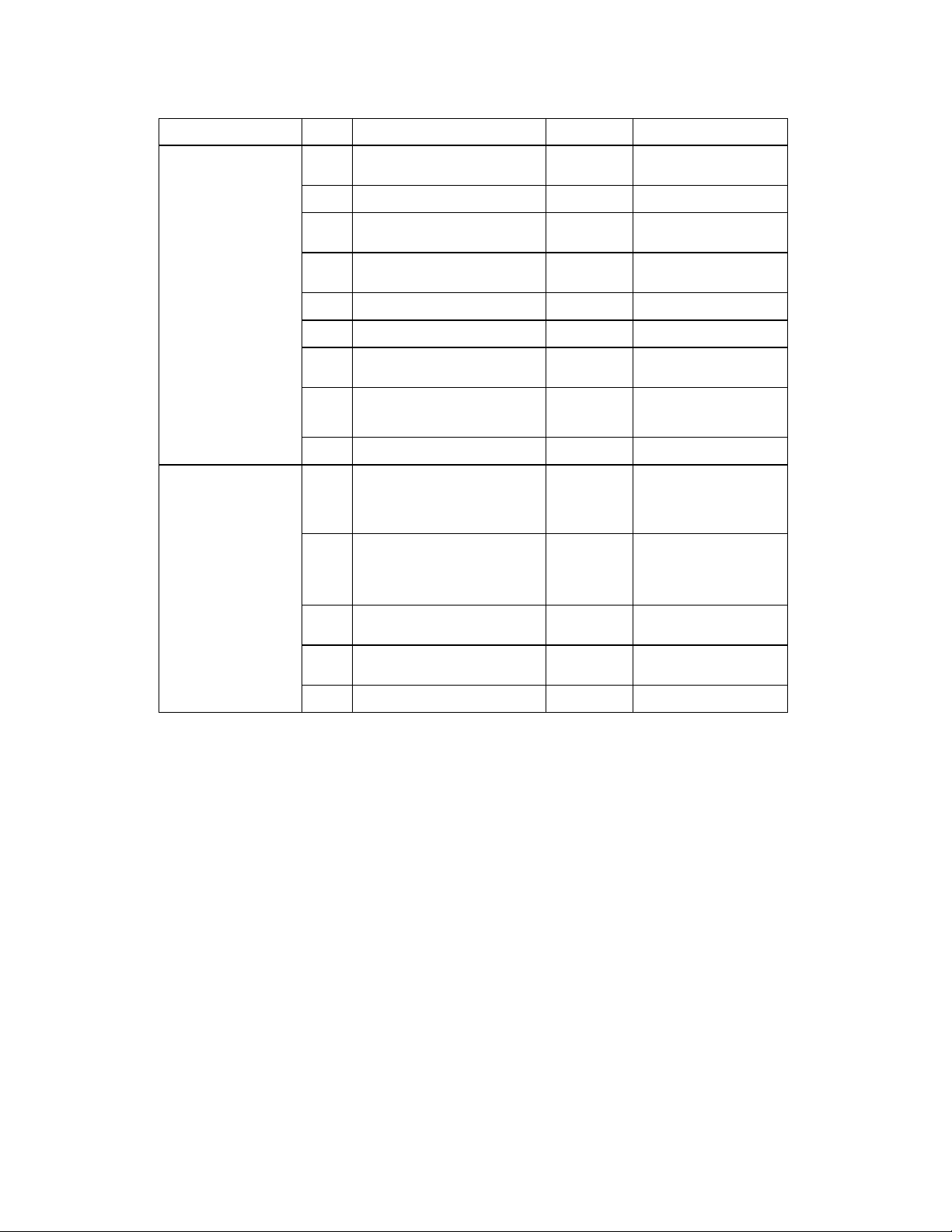

18 Table 1 ..................................................................................................................................

18