Contents

1 Legal Information.........................................................................................................4

2 About this Document..................................................................................................5

2.1 Objective and Target Group..............................................................................5

2.2 Explanation of Symbols....................................................................................5

2.2.1 Typographic Conventions................................................................. 5

2.2.2 Symbols Used.................................................................................... 5

2.3 Figures................................................................................................................6

2.4 Downloading Manuals...................................................................................... 6

3 Safety............................................................................................................................7

3.1 Intended Use......................................................................................................7

3.2 General Safety Instructions.............................................................................. 7

3.3 Organizational Measures.................................................................................. 7

3.3.1 User Manual....................................................................................... 8

3.3.2 General Personnel Qualification.......................................................8

4 Product Description..................................................................................................... 9

4.1 Model Overview.................................................................................................9

4.2 Product Labeling................................................................................................9

4.2.1 Type Plate........................................................................................... 9

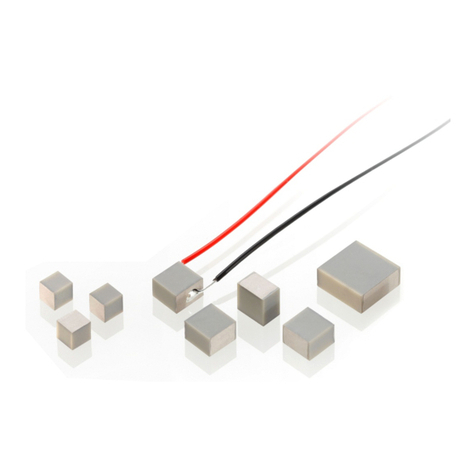

4.3 Scope of Delivery...............................................................................................9

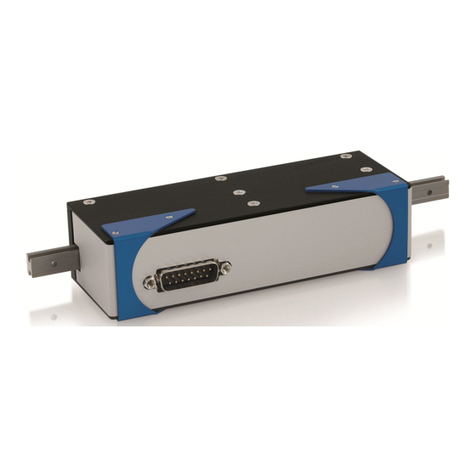

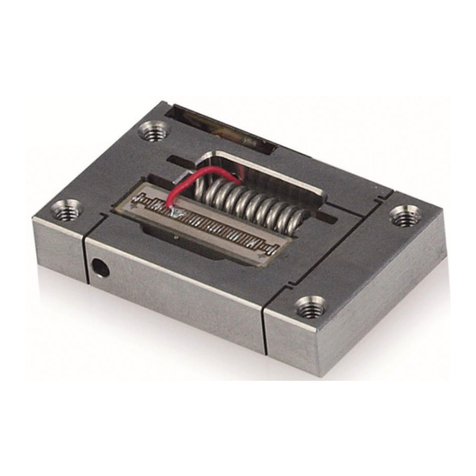

4.4 Overview.......................................................................................................... 10

4.5 Suitable Electronics......................................................................................... 10

5 Unpacking...................................................................................................................11

6 Installation................................................................................................................. 12

6.1 Avoiding Mounting Errors.............................................................................. 12

6.2 Mounting the P-844 and Connecting to a Protective Earth Conductor........13

6.3 Fixing the Load................................................................................................ 14

6.4 Connecting the P-844.......................................................................................15

7 Startup / Operation................................................................................................... 16

7.1 Determining the Operating Parameters.........................................................16

7.1.1 Calculating the Effective Mass........................................................16

7.1.2 Calculating the Maximum Operating Frequency of the Loaded

Piezo Actuator.................................................................................. 17

7.1.3 Calculating the Forces that Occur During Dynamic Operation.... 17

7.1.4 Calculating the Power Requirement for Sinusoidal Operation.... 17

7.2 Starting and Operating the P-844................................................................... 18

7.3 Discharging the P-844...................................................................................... 20

8 Maintenance...............................................................................................................22

8.1 Cleaning............................................................................................................22

CONTENTS P844M0001EN ‒ 11/13/2018

2MOTION | POSITIONING