Pilz PSSuniversal multi PSSu H m F DPsafe SN SD User manual

Other Pilz Control System manuals

Pilz

Pilz PSSu H PLC1 FS SN SD Series User manual

Pilz

Pilz PSS67 IO1 16FDI User manual

Pilz

Pilz PMCprimo C User manual

Pilz

Pilz PNOZmulti Series User manual

Pilz

Pilz PNOZ m ES EtherCAT User manual

Pilz

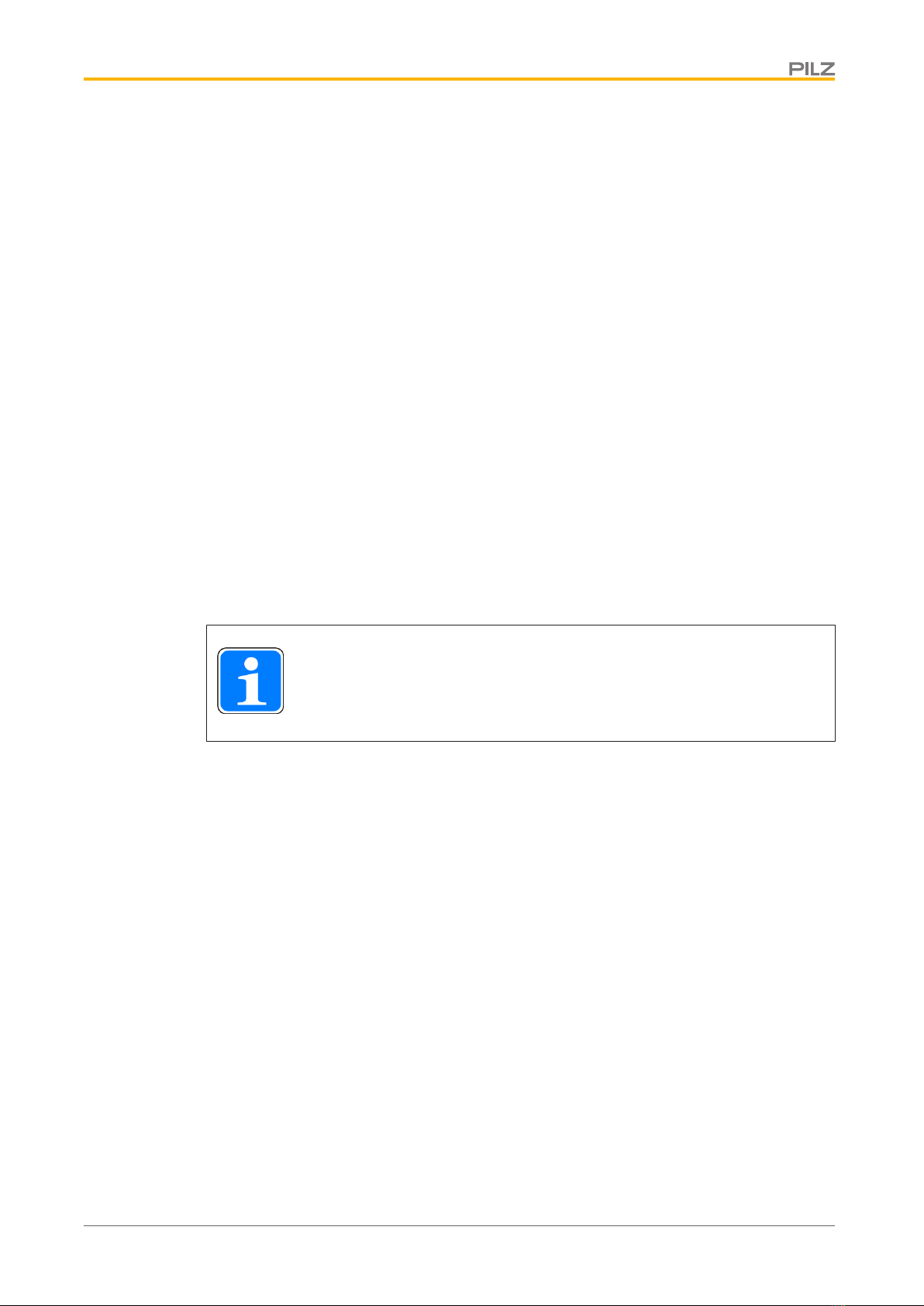

Pilz PNOZ mmc2p User manual

Pilz

Pilz PSS u2 ES 4DO SR 0.5A User manual

Pilz

Pilz PNOZ ml1p User manual

Pilz

Pilz PNOZ mmc6p User manual

Pilz

Pilz PSS u2 ES 4DO R 8A User manual

Pilz

Pilz PNOZ m ES 14DO User manual

Pilz

Pilz PSSu E S 2AI I se-T User manual

Pilz

Pilz PSS u2 B1 User manual

Pilz

Pilz PNOZ m ES Profinet User manual

Pilz

Pilz PSS u2 ES 4IOL User manual

Pilz

Pilz PSS67 PLC1 16FDI User manual

Pilz

Pilz PSS u2 EF 8DI User manual

Pilz

Pilz PSS u2 ES 16DI User manual

Pilz

Pilz PSSu E F 2DOR 8 User manual

Pilz

Pilz PMCprimo C2 User manual

Popular Control System manuals by other brands

Zonex

Zonex GEN II -VVT Installation and application manual

Altronics

Altronics K 9650 quick start guide

micro-trak

micro-trak RoadMaster Reference manual

micro-trak

micro-trak Calc-An-Acre II Reference manual

EMKO

EMKO TRANS-SYNCRO user manual

Dover

Dover TWG GC ELEMENT II Calibration and Troubleshooting Manual