PNOZ s6.1

Operating Manual PNOZ s6.1

21692-EN-08 3

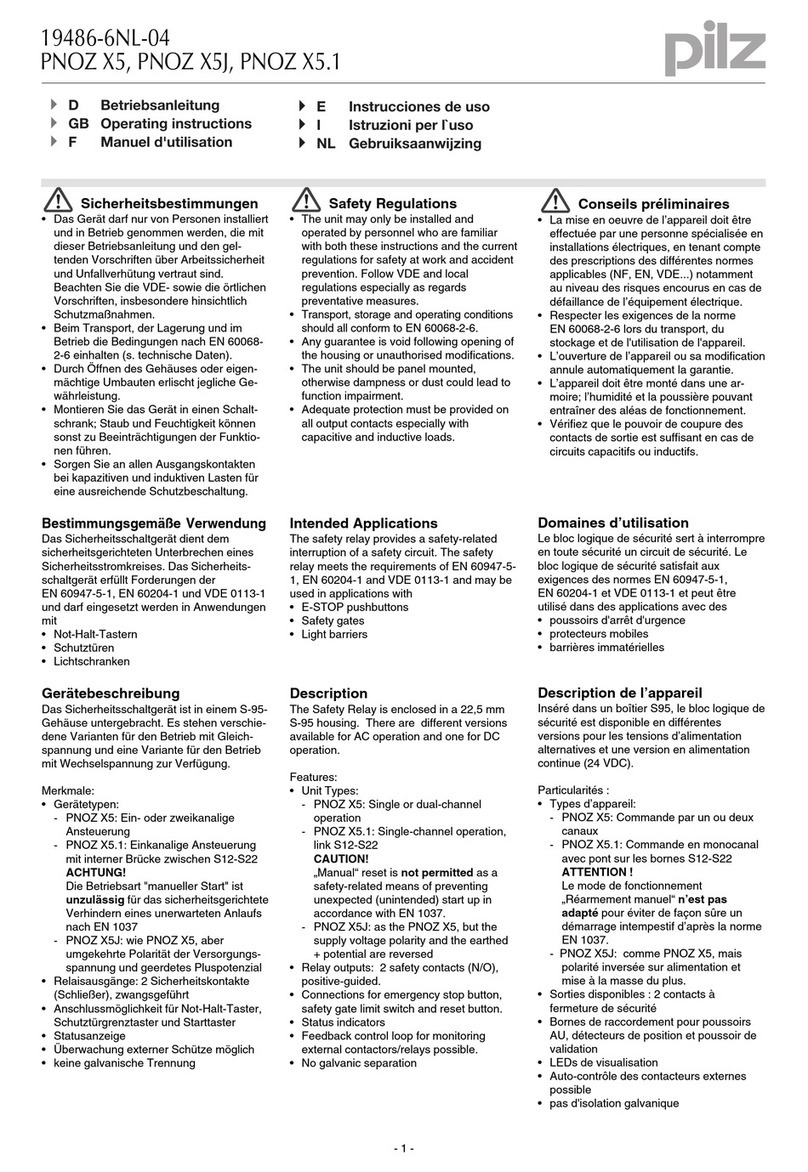

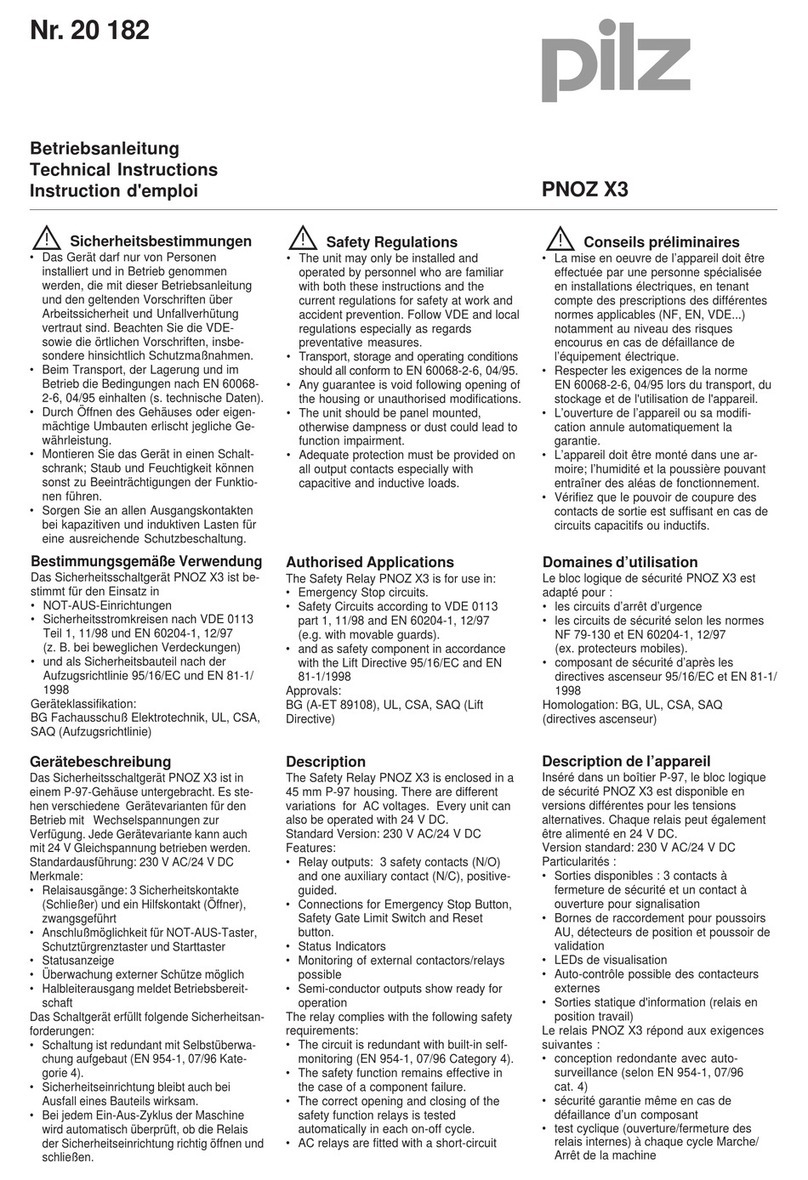

Safety relay PNOZ s6.1

The safety relay can be used as a two-hand control relay or for simultaneity monitoring.

The safety relay meets the requirements of EN 60947-5-1, EN 60204-1 and VDE 0113-1

and may be used in applications with

}E-STOP pushbuttons

}Safety gates

The two-hand control relay meets the requirements of EN 574 Type IIIA. It forces the oper-

ator to keep his hands outside the danger zone area during the hazardous movement. It is

designed for use in two-hand circuits.

ATTENTION!

The two-hand control relay may not be used on press controllers. It is only

suitable for use where the risk analysis has established a low level of risk

(e.g. EN 954-1 Cat. 1 and EN ISO 13849-1 Cat. 1).

For your safety

}Only install and commission the unit if you have read and understood these operating

instructions and are familiar with the applicable regulations for health and safety at work

and accident prevention.

Ensure VDE and local regulations are met, especially those relating to safety.

}Any guarantee is rendered invalid if the housing is opened or unauthorised modifica-

tions are carried out.

}The supply voltage for the two-hand relay must only be connected after the shutdown

device in accordance with § 9 VBG 7n5.1/2.

}To avoid inductive and capacitance coupling, the cables between the two-hand relay

and the pushbuttons must be run separately to any power cables.

}On account of the low currents you should use gold-plated pushbutton contacts.

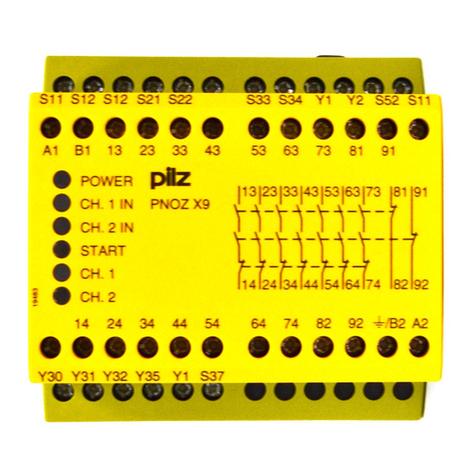

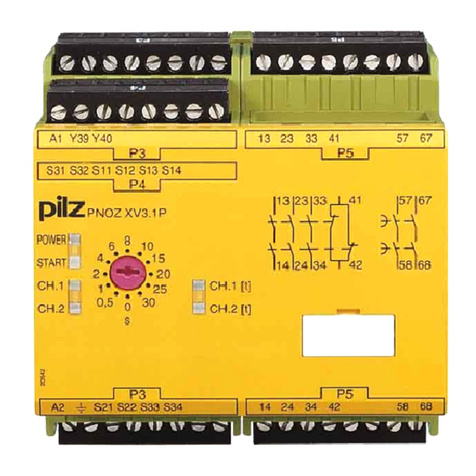

Unit features

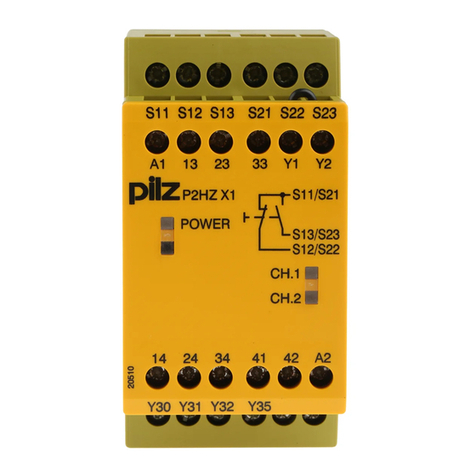

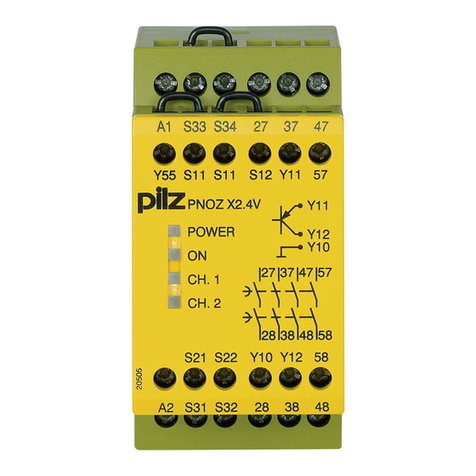

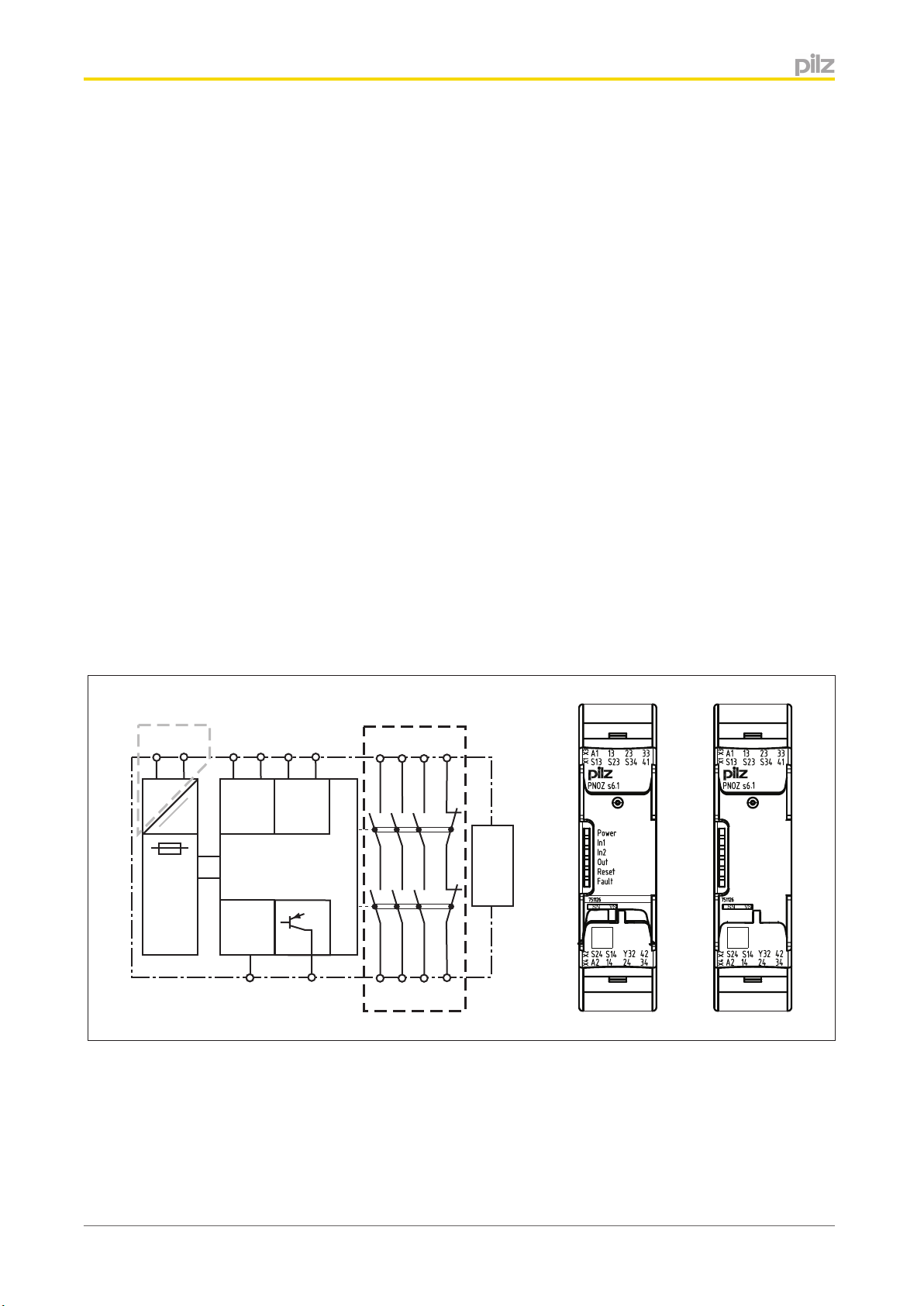

}Positive-guided relay outputs:

– 3 safety contacts (N/O), instantaneous

– 1 auxiliary contact (N/C), instantaneous

}1 semiconductor output

}Connection options for:

– 2 control elements (pushbuttons)

– Emergency stop pushbutton

– Safety gate limit switches

}A connector can be used to connect 1 PNOZsigma contact expansion module

}LED for:

– Supply voltage

– Input status, channel 1