Table of Contents

Safety Information..................................................................................................................2

Functional Description...........................................................................................................3

Installation instruction............................................................................................................3

Electrical Connection.............................................................................................................4

Commissioning.......................................................................................................................4

Maintenance and Cleaning....................................................................................................5

Troubleshooting.....................................................................................................................5

Safety Information

General Instructions

To ensure safe operation, the device should only be operated according to the specifica-

tions in the instruction manual. The requisite Health & Safety regulations for a given appli-

cation must also be observed. This statement also applies to the use of accessories.

Every person who is commissioned with the initiation or operation of this device must have

read and understood the operating instructions and in particular the safety instructions!

The liability of the manufacturer expires in the event of damage due to improper use, non-

observance of this operating manual, use of insufficiently qualified personnel and unau-

thorized modification of the device.

Proper sage

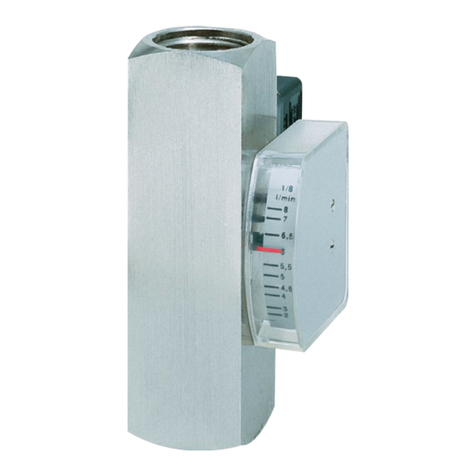

The calorimetric compact flowmeters type DTL06 are used for measuring air flows. Any

other use of the device is prohibited and outside the scope of application.

In particular, applications in which shock loads occur (for example, pulsed operation)

should be discussed and checked in advance with our technical staff.

The series DTL06 flow meter devices should not be deployed as the sole agents to pre-

vent dangerous conditions occurring in plant or machinery. Machinery and plant need to

be designed in such a manner that faulty conditions and malfunctions do not arise that

could pose a safety risk for operators.

Dangerous substances

For dangerous media such as e.g. Oxygen, Acetylene, flammable or toxic substances as

well as refrigeration systems, compressors, etc. must comply with the relevant regulations

beyond the general rules.

DTL06 Instruction manual 05/2021 page 2