[3]

Stand cabinet upright and make sure the frame work is square and that

the doors are in line, then tighten all bolts.

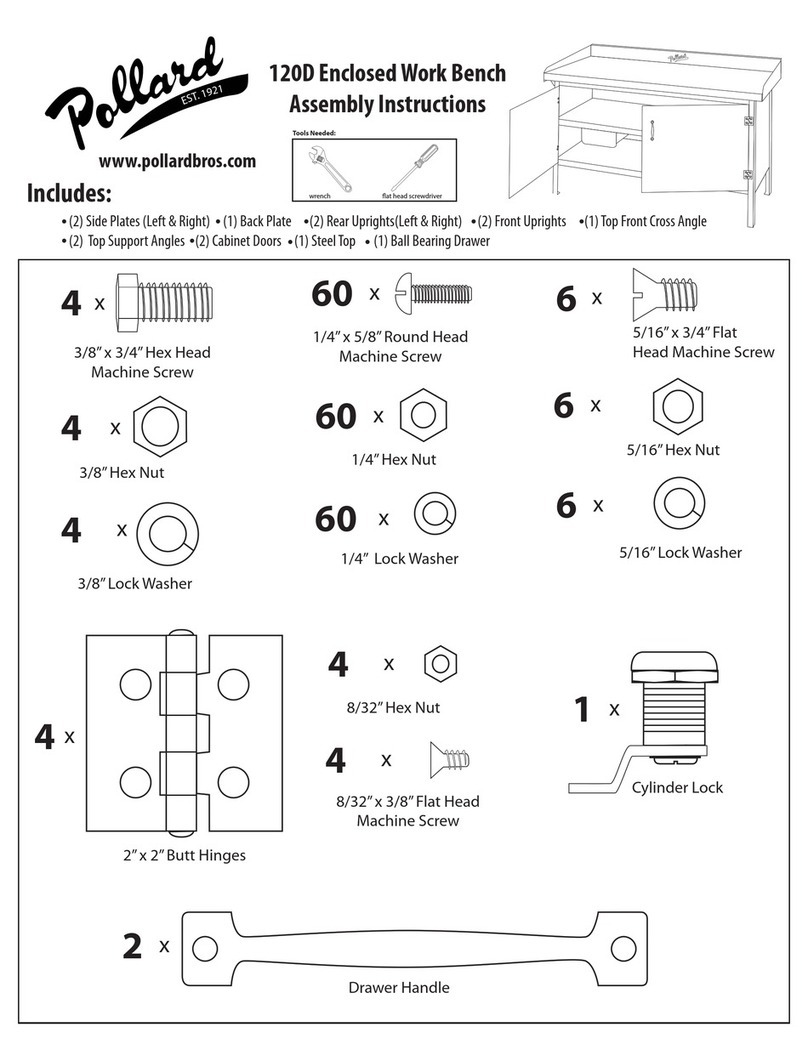

Attach front Uprights using (16) 1/4” x 5/8”

Round Head Machine Screws, 1/4“ Lock Wash-

ers, and 1/4”Hex Nuts. HAND TIGHTEN ONLY.

Bolt the top front cross angle inside of the front

uprights at the top with angle ange facing in.

Use (4) – 1/4” x 5/8” Round Head Machine

Screws, Lock Washers, and Hex Nuts. HAND

TIGHTEN ONLY.

Assemble Hinges to left and right Doors using

(4) 2” x 2” hinges, match up holes on uprights

with holes on hinges and bolt together using

(16) 1/4” x 5/8” Machine Screws, 1/4”Lock Wash-

ers, and Hex Nuts.

6

7

8

9

Cabinet Front

Attach Cylinder Locks to Cabinet Fronts.

Remove End Screw, Cam, and 1/2” Hex Nut from

Cylinder. Insert Cylinder into lock hole and

replace 1/2”Hex Nut, Cam, and End Screw

according to diagram. Attach door handles with

(4) 8/32“ x 3/8” Flat Head Machine Screws and

8/32” nuts.