Pollard Brothers Manufacturing 5504 N. Northwest Highway Chicago IL 60630

.. .

.

phone(773)763-6868 fax(773)763-4466 toll free(800) 551-5566

[4]

14 Insert Drawer slide on drawer into the drawer

slide on the drawer cover. After inserting

drawer, fully close drawer to ensure drawer

has locked. Note: To detach the drawer

depress black lever up on right and down on

left slides simultaneously as you pull the drawer

out.

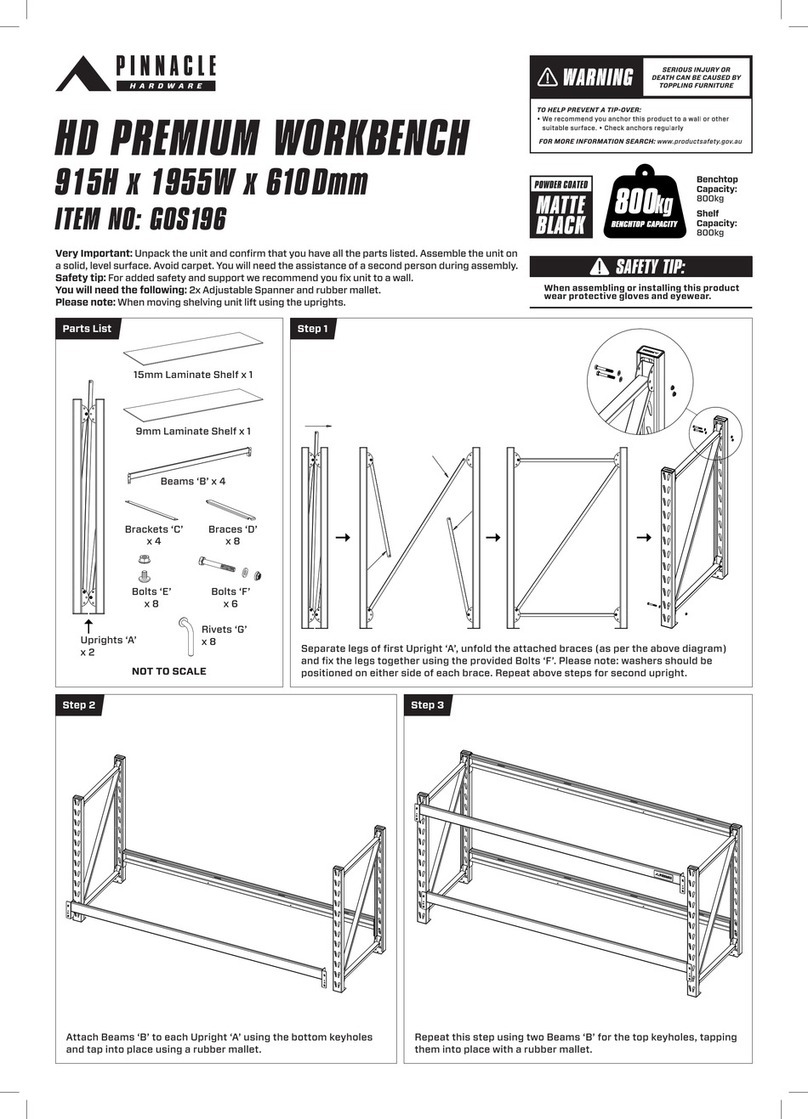

Attach top support angles to Uprights and

Sides using (4) 3/8” x 3/4” Hex Head Machine

Screws, 3/8” Lock Washers, and 3/8” Hex Nuts.

Slide the formed 12 ga. Steel Top from either end

over the top support angles, (formed side with

5/16” holes to the back).

Fasten Back Plate inside the 1”form of the End

Plates and with the ¾”form facing out use (5) ¼” x

5/8” Round Head Machine Screws, 1/4” Lock Wash-

ers and 1/4” Hex Nuts, three to the top and two for

the End Plates. Tighten all bolts

Before bolting the top to the support angles, slip

in the End Plates between the Top and the angles,

match up the holes and secure Top and End Plates

to the support angles using (6) 5/16” x 3/4”Flat

Head Machine Screws, 5/16“ Lock Washers, and

Hex Nuts.

10

11

12

13