Precor Experience TRM700-16 User manual

Other Precor Treadmill manuals

Precor

Precor PRECISION SERIES Technical manual

Precor

Precor C932i User manual

Precor

Precor Experience Series 700 Line User manual

Precor

Precor Treadmill EFX534 User manual

Precor

Precor 903 User manual

Precor

Precor 9.21 User manual

Precor

Precor M 9.1 User manual

Precor

Precor ENERGY SERIES User manual

Precor

Precor 9.17 Technical document

Precor

Precor C952i User manual

Precor

Precor C942 User manual

Precor

Precor TRM 800 Assembly Instructions

Precor

Precor Teambike 800 User manual

Precor

Precor TRM 211 User manual

Precor

Precor TRM 211 Technical manual

Precor

Precor M9.21i User manual

Precor

Precor Experience Series 700 Line User manual

Precor

Precor C954 User manual

Precor

Precor M9.41si User manual

Precor

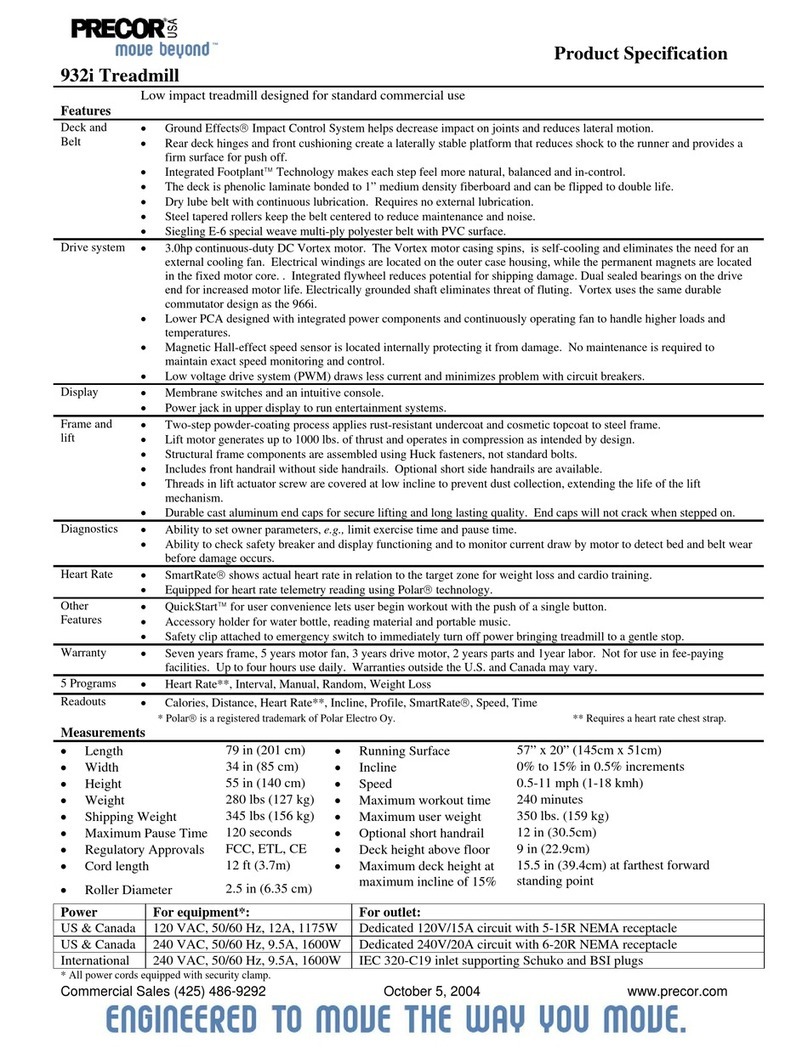

Precor Treadmills 932i Owner's manual