Prexiso PR500HVG User manual

IMPORTANT:

Read before Using EN

PR500HVG

SELF-LEVELING ROTARY LASER

www.prexiso-eu.com

WARRANTY

LIMITED

YEARS

2

1

PR500HVG

IMPORTANT SAFETY INSTRUCTIONS

Do not use the product before you have studied the Safety instructions and the

User Manual on the enclosed CD or on our Homepage.

If you have no such manual, or it is in the wrong language, please ask your agency

for an appropriate copy.

The product is permitted to use for skilled persons only.

WARNING:

•

It is a Class 2 laser product in accordance with IEC 60825-1:2014

•

The following labels are on your laser tool for your convenience and safety.

•

Do not stare into the laser beam or direct it towards other people unnecessarily.

•

Don't dazzle other individuals.

A measurement could be triggered at any time.

•

Looking directly into the beam with optical aids can be hazardous.

•

Do not operate the product in explosion hazardous areas or in aggressive

environments.

•

Only use chargers recommended by the manufacturer to charge the batteries.

•

Keep extremities in a safe distance from the moving parts.

•

Watch out for erroneous measurements if the product is defective or if it has been

dropped or has been misused or modified.

•

Carry out periodic test measurements.

Particularly before, during and after important measurements.

•

The product and batteries must not be disposed of with household waste.

2

LASER RADIATION!

Do not stare into beam

Class 2 laser

< 1mW 500-540nm

IEC 60825-1:2014

WARNING!

The goggles do not protect your eyes against the laser beam.

They are only used to increase the visibility of the laser.

Goggles:

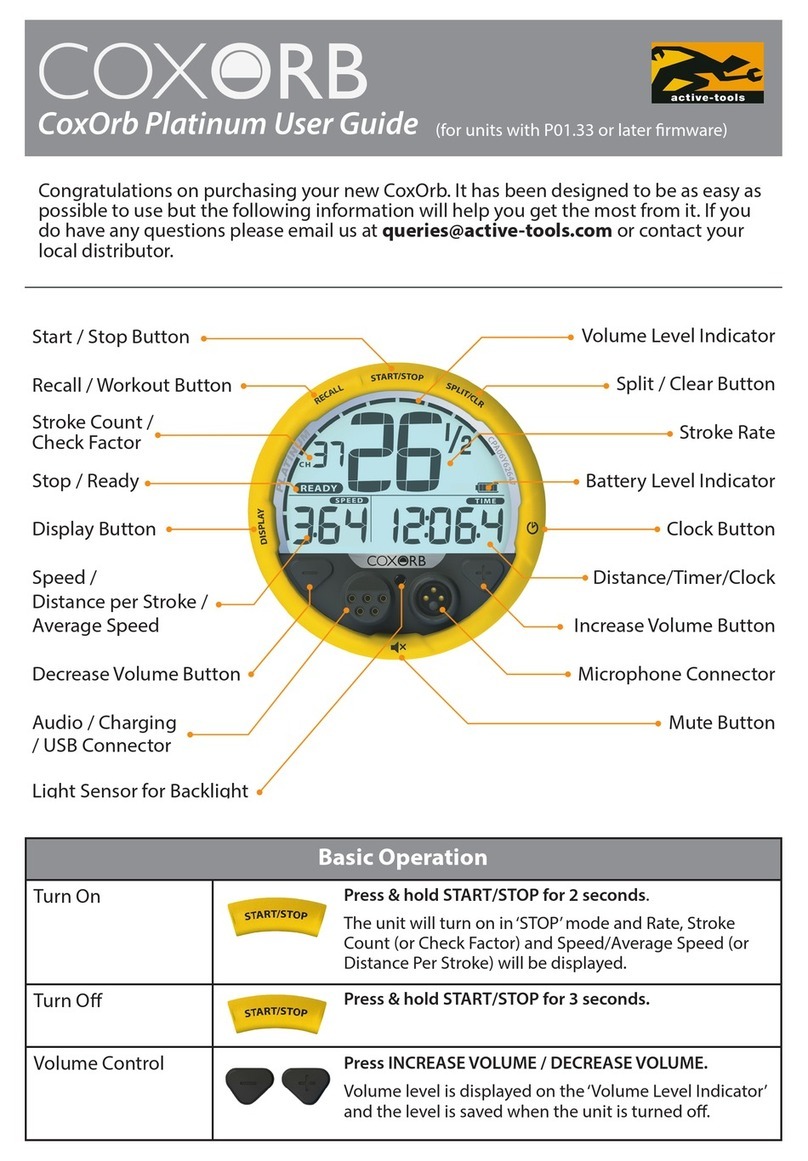

PRODUCT OVERVIEW

PARTS DESCRIPTION

A

B

C

D

E

F

G

Alignment Sight

Vertical Up Beam Window

Rotary Laser / Glass Enclosed

Keypad

Battery lock switch

Power Adapter Plug Jack

Vertical support dot

PARTS DESCRIPTION

H

I

J

K

L

M

N

5/8" insert

5/8" insert

Charger

Plug(EU, China)

Plug(US, Japan, China)

Plug(Australia)

Plug(UK)

A

B

C

D

E

F

G

H

I

3

K

N

M

L

PR500HVG

J

KEYPAD AND LED

Up

On/Off Tilt warning on/off

Scan mode

/Speed Slope

Down Left Right

LEDs

POWER-LED

MAN-LED

•

Blinking Green: Laser Tool is Auto-Leveling In

Calibration and / or Default Tilt Warning Set Up

•

Solid Green: Auto-Leveling Complete

•

Blinking Red: Low Battery

•

Solid Red: Battery Needs Recharging

•

Solid Red With POWER-LED – Solid Green:

Manual Mode On (Auto-Leveling Off)

•

Blinking Red With POWER-LED – Blinking

Green: Out of Compensation Range

•

Solid Green: Tilt Warning On

•

Solid Red: Tilt Warning Alarm

•

Solid Green: X Axis Adjust Slope Mode

•

Blinking Green:

X Axis at Maximum Allowed Slope in Slope Mode

X Axis Adjust Calibration Mode

•

Solid Red: Y Axis Adjust Slope Mode

•

Blinking Red:

Y Axis at Maximum Allowed Slope in Slope Mode

Y Axis Adjust Calibration Mode

TILT

Y/Z

4

PR500HVG

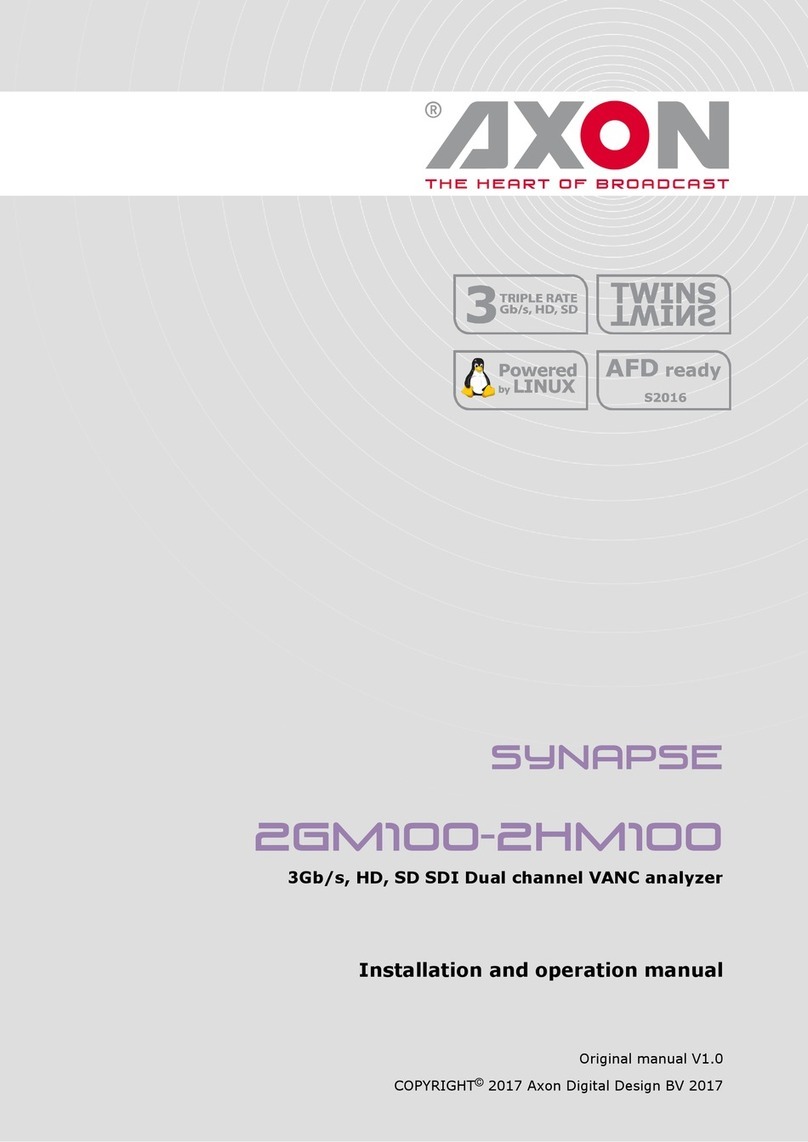

RC300 REMOTE CONTROL

5

RC300

+

-

%

1. Light indicator

2. Speed switch button(Press this button to switch the laser

beam rotating speed from 300rpm->600rpm->0rpm->300rpm).

3. Laser dot moving button (Press this button to clockwise

move the laser dot).

4. Speed switch button(Press this button to switch the laser

beam rotating speed from 300rmp->0rpm->600rpm->300rpm.

5. Slope

6. Laser dot moving button (Press this button to anticlockwise

move the laser dot).

7. Scan mode/Speed

8. Battery lid (Open the battery lid and insert

2 x1.5V AA batteries into the battery compartment).

1

5

6

7

8

2

3

4

BATTERIES AND POWER

WARNING:

•

Use charging / power adapter only with Li-Ion battery pack supplied.

Charging any other type of battery may result in damage and/or personal harm.

•

The battery and charging / power adapter can be damaged if damp.

Always store and charge the tool in a dry and covered place.

NOTE:

•

For best battery life, it is recommended to charge the battery once it has been fully

discharged and avoid letting charge for >10 hours at a time.

Operating with Charging / Power Adaptor

•

Laser tool can operate while plugged into charging / power adapter.

Functions and controls of laser tool are the same as when not plugged into

charging / power adapter.

WARNING:

•

Pay close attention to the battery

holder’s (+) and (-) markings for

proper battery insertion. Batteries

must be of same type and

capacity. Do not use a combination

of batteries with different

capacities remaining.

Battery Installation / Removal

Li-Ion Battery version

Alkaline Batteries version

6

PR500HVG

SET UP

OPERATION

Operation in Auto Mode

•

Press to turn on the instrument.

•

Green LED is blinking green when the instrument start to leveling.

TILT LED is off (TILT Function is not on by default), the laser is glitter.

•

After leveling, the laser dot starts to rotate(the default speed is 300rpm),laser

is kept bright, Green LED and TILT LED are solid green.

•

The instrument will be warning when it is tilted, and rotating will be stopped, the

laser will be glitter, TILT LED is solid red. Press to reset.

•

Press to turn off the instrument.

Horizontal Position

•

Place laser tool down on its bottom.

Be sure surface is near level.

•

Press to power ON.

At Angle

•

Press to power ON. Press and hold to turn ON Mnual Mode. Laser tool can now

be positioned to various angles with auto-leveling mode OFF.

NOTE:

To change between horizontal and vertical positions the laser tool must be powered

OFF, repositioned, and then powered ON in the new position.

Vertical Position

•

Place laser tool down on its side,

handle facing up. Be sure surface

is near level.

•

Press to power ON.

7

Operation in Manual Mode

•

Press and hold for 3 seconds to turn on Manual Mode when the instrument is

in Auto Mode or TILT Mode.

Green LED is solid green, and Red LED is solid red.

•

The Auto-leveling function is off, the instrument can place at any less

than 50°angle.

•

Press and hold for 3 seconds in Manual Mode to turn off Manual Mode, the

instrument will back to Auto-leveling Mode.

Speed Switch/Spot Mode

•

After Powered on and Auto-leveling or in Manual Mode (Not in SLOPE function),

the default speed is 300rpm:

(1) Short press to switch speed, followed by looping from

300rpm->600rpm->0rpm->300rpm;

(2) Short press to switch speed, followed by looping from

300rpm->0rpm->600rpm->300rpm.

•

At 0rpm or Scan Mode(Not in SLOPE function):

(1) Press the laser dot will anticlockwise motion;

(2) Press the laser dot will clockwise motion;

At 0rpm:

(1) Short press / the rotation angle of laser dot is 10°.

(2) Long press / the laser dot will rotate at 0.5-1rpm.

(3) Press and hold / >4 seconds, the laser will blinking

3 times to remind the laser start to speed up, after that the laser

will rotate at 7.5-10rpm.

(4) Release / the laser dot will back to 0rpm.

•

In Scan Mode:

(1) Short press / the scan angle will rotate 6°, the scan function is kept.

(2) Long press / the scan will be stopped, the laser dot willrotate at

0.5-1rpm.

(3) Press and hold / >4 seconds, the laser will blinking 3 times to remind

the laser start to speed up, after that the laser will rotate at 7.5-10rpm.

(4) Release / it will back to scan function.

Remark:

When the rotation speed is switched from 300rpm to 0rpm for 0.5 seconds,

the output power of instrument will be low power, switched from 0rpm to scan

function or rotation for 1 second, it will be high power.

8

Scan Mode

•

Turn on the Scan Mode:

(1) Short press to turn on scan function, the default angle is 15°

(2) Short press again to turn off scan function.

•

Scan angle switch:

(1) Short press to switch the scan angle, followed by loop from

15°->30°->60°->15°.

(2) Short press to switch the scan angle, followed by loop from

15°->60°->30°->15°.

TILT function

TILT Operation and Reset

•

Press to turn on the instrument;

LED is blinking green when the instrument start to leveling.

Short press , the TILT LED will be solid green, the laser is glitter.

•

After Auto-leveling, the laser starts to rotate.

•

After Auto-leveling, if the instrument is tilted, it will be warning, the rotation will be

stopped, and the laser is kept bright. TILT LED is solid red.

•

Press again, the instrument will reset and enter TILT function again, and

re-leveling.

TILT Mode switch

•

Press to switch to Auto-leveling Mode in TILT Mode, TILT LED will be off.

Remark:

When the instrument is in Manual Mode, it can not switch to TILT

function; If necessary, please resume to Auto Mode.

Operation in Slope function

Horizontal Slope function:

•

First to turn on the Manual Mode after the instrument is powered on.

The is solid green, and the is solid red.

Short press to enter the slope function, the LED is solid green ,

it indicates the instrument is in X axis manual slope function.

Remark:

(In TILT Mode also need to enter the Manual Mode first, then press to enter the

slope mode).

•

/ can control the laser tilt along the X axis.

9

Press the laser will raise at +X direction of the instrument.

Press the laser will lower at +X direct of the instrument.

*A single short press the laser will tile 20".

*Press and hold / >1 second, the laser will tile 15'/second.

*Press and hold / >4 seconds, the laser will tile 1°/second.

•

The will blinking green when the tile is over run. Release / , the

will be solid green.

•

Press to switch to Y axis manual slope functuon, the is solid red.

•

/ can control the laser tilt along the Y axis.

Press the laser will raise at +Y direction of the instrument.

Press the laser will lower at +Y direct of the instrument.

(The key-hold time and adjustment amount are same as X axis.)

•

The will blinking green when the tile is overrun.

Release / , the will be solid green.

•

Short press to quit slope function, and back to Manual Mode.

The is off, is solid green and is solid red;

The horizontal slope function can only be entered in Manual Mode,

it will resume to Manual Mode when quit the slope function.

Vertical Slope function:

•

When powered on in vertical state, enter the Auto-leveling Mode, the

is blinking green, and the instrument starts to leveling.

Short press to enter the vertical slope function(Z axis is Autoleveling),

the is solid red.

(In vertical TILT Mode also can enter Slope Mode, TILT and Slope

function can exist concurrently)

•

The operation of vertical slope function is the same as horizontal slope function.

•

Short press to quit slope function, and resume to Auto Mode.

10

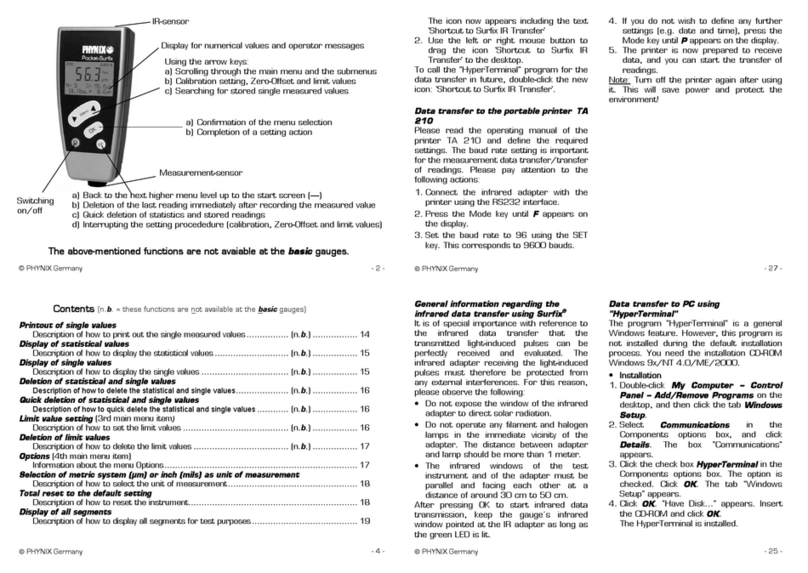

Accuracy Check and Calibration

Y+

X+

X-

Y-

A

B

11

X1

D1

D1

D2

D0

20 m

20 m

1

3

X2

Y1

D2

20m

20m

2

4

2 m

D1

1 m

2 m

1 m

D2

D1D2

D0

A

B

A

B

C

E

12

NOTE:

•

See Feature Set to reference which models offer specific functions.

•

The laser tools are sealed and calibrated at the factory to the accuracies specified.

•

It is recommended to perform a calibration check prior to its first use and then

periodically during future use.

•

Be sure to allow the laser tool adequate time to Auto-Level (< 60 seconds) prior to

a calibration check.

•

The laser tool should be checked regularly to ensure its accuracies, especially for

precise layouts.

Horizontal Check (See Figure C )

•

Set the laser tool on a tripod 20 m away from a wall with the ”X1” side

facing the wall ( C1).

•

Power ON the laser tool and allow the laser tool to Auto-Level and be sure laser is

rotating.

•

Go to the wall and mark a reference point “D1” where the laser line is on the wall.

If available, using a detector may help in locating the beam more easily.

•

Loosen the laser tool from the tripod and rotate the laser tool 180° so

that the “X2” side is now facing the wall ( C2).

•

Go back to the wall and measure the distance between the first

reference point “D1” and the second reference point “D2” ( C3).

•

There is no need to adjust calibration if the distance between reference

point “D1” and “D2” is < 2 mm.

•

If the distance measured is ≥ 2 mm then a calibration adjustment is necessary.

•

Perform the same steps for the “Y” axis as was done for the “X” axis.

Replace “X1” and “X2” with Y1” and “Y2” ( C4).

Vertical Check (See Figure E )

(Only necessary on models with Vertical Auto-Leveling)

•

Set the laser tool on a stable surface in its vertical position 1 m away from

a wall that extends ≥ 2 m high with the “Y1” side facing that wall.

•

Power ON the laser tool and allow the laser tool to Auto-Level and be

sure laser is rotating.

•

Mark reference points “A” (where laser line is on floor 1 m away from wall), “B”

(where laser beam is at corner), and “D1” (where laser beam is 2 m up the wall).

•

Rotate the laser tool 180° so that the “Y2” side is now facing the wall.

•

Align the laser beam with reference points “A” and “B” and then go back to the wall

and measure the distance between the reference points “D1” and “D2”.

•

There is no need to adjust calibration if the distance between reference point

“D1” and “D2” is < 1 mm.

•

If the distance measured is ≥ 1 mm then a calibration adjustment is necessary.

13

SPECIFICATIONS

Horizontal Rotary Accuracy:

Vertical Rotary Accuracy:

Vertical Up Beam Accuracy:

Compensation Range:

Slope Range:

Minimum Increment:

Scan Range:

Working range with Detector (φ)

Leveling Time:

Rotation Speed:

Laser Class:

Laser Wavelength:

Operating Time:

Recharging Time:

Power Supply:

IP Rating:

Operating Temperature Range:

Storage Temperature Range:

±1.5 mm @ 30 m

±3 mm @ 30 m

±3 mm @ 30 m

±5°

±10%

0.01%

15°, 30°, 60°

0.5m ~ 600m

≤ 20 seconds

Class 2 (EN60825-1)

500-540nm

30 h(Li-Ion Battery Pack) / 20 h(4 * 2# Batteries)

≤ 8 h

Li-Ion Battery Pack / 4 * 2# Batteries

IP66

-10° C ~ +40° C

-20° C ~ +60° C

600/300/0 rpm ±10%

14

•

Handle measuring devices with care.

•

Clean the device after every use with a soft cloth. If necessary, dampen the cloth

with water.

•

If the instrument gets wet, clean it and dry it carefully.

•

Only put the laser away when it is completely dry.

•

Remove the batteries or rechargeable batteries when switching off the laser for a

long time.

•

Do not use solvent to clean the laser.

•

Only transport the laser in its original case.

Do not leave the Prexiso laser in direct sunlight. Do not expose the laser to high

temperatures.

The laser body and some internal parts are made of plastic and can warp at high

temperatures. Do not store the laser in a very cold environment, as this can cause

condensation to form on the internal parts when the laser is warmed up. This can

mist up the beam windows and cause the internal circuit boards to rust.

POSSIBLE ERRORS

If the measurements calculated by the laser are incorrect, this could

be caused by :

•

use of the laser near plastic or glass windows.

•

dirt or obstruction of the beam windows.

•

the laser may have fallen over without your knowledge. This highlights the

importance of regularly checking the laser’s precision.

•

extreme changes in temperature, e.g. using the laser in a cold environment after

storing it in a warm environment. Wait a few minutes for the device to reach room

temperature.

WARRANTY AND RESPONSIBILITY

The device has a 2-year basic warranty. This warranty does not cover breakdowns

or faults which may have been caused by :

•

incorrect use of the device.

•

non-respect of the instructions described In the user manual.

•

off cuts, poor handling, use of unsuitable batteries, poor electrical connections etc.

Repairs made other than by our factory, Prexiso service centre or authorized service

station relieve Prexiso of further liability under this guarantee. This guarantee is

made expressly in place of all other guarantees or warranties, ex- pressed or

implied, with respect to quality, merchantability, or fitness for a particular purpose.

MAINTENANCE AND CARE

15

DISPOSAL

LASERS ARE DESIGNED TO CARRY OUT ALL TYPES OF WORK

REQUIRING HORIZONTAL OR VERTICAL ALIGNMENTS. ALL

DEVICES ARE CHECKED AND THEN SHIPPED WITH PERFECT

SETTINGS, BUT SHOULD ANY IMPACT OCCUR, A DEVICE MAY

LOSE PRECISION OR EVEN COMPLETELY LOSE ITS SETTINGS.

THE USER MUST CHECK THE DEVICE REGULARLY AND

BEFORE CARRYING OUT SUBSTANTIAL WORK.

We shall accept no responsibility for problems regarding the

construction, installation, manufacture or assembly which

may result from a device failure due to poor maintenance

or hazardous connections to other devices.

RoHS-compliance

This product complies with the directive 2011/65/EU.

CAUTION

The battery must not be disposed with household waste. Care for the

environment and take them to the collection points provided in

accordance with national or local regulations.The product must not be

disposed with household waste. Dispose of the product appropriately in

accordance with the national regulations in force in your country.

Adhere to the national and country specific regulations.

16

Lithium

Prexiso AG

Fabrikstrasse 1

CH-8586 Erlen / Switzerland

Internet: www.prexiso-eu.com

Table of contents

Other Prexiso Measuring Instrument manuals

Prexiso

Prexiso PMX-42A User manual

Prexiso

Prexiso XL2 User manual

Prexiso

Prexiso P30M User manual

Prexiso

Prexiso P20LI User manual

Prexiso

Prexiso P70DLI User manual

Prexiso

Prexiso PTX-99 User manual

Prexiso

Prexiso P20 User manual

Prexiso

Prexiso PMX-42B User manual

Prexiso

Prexiso P40A User manual

Prexiso

Prexiso G5 Series User manual