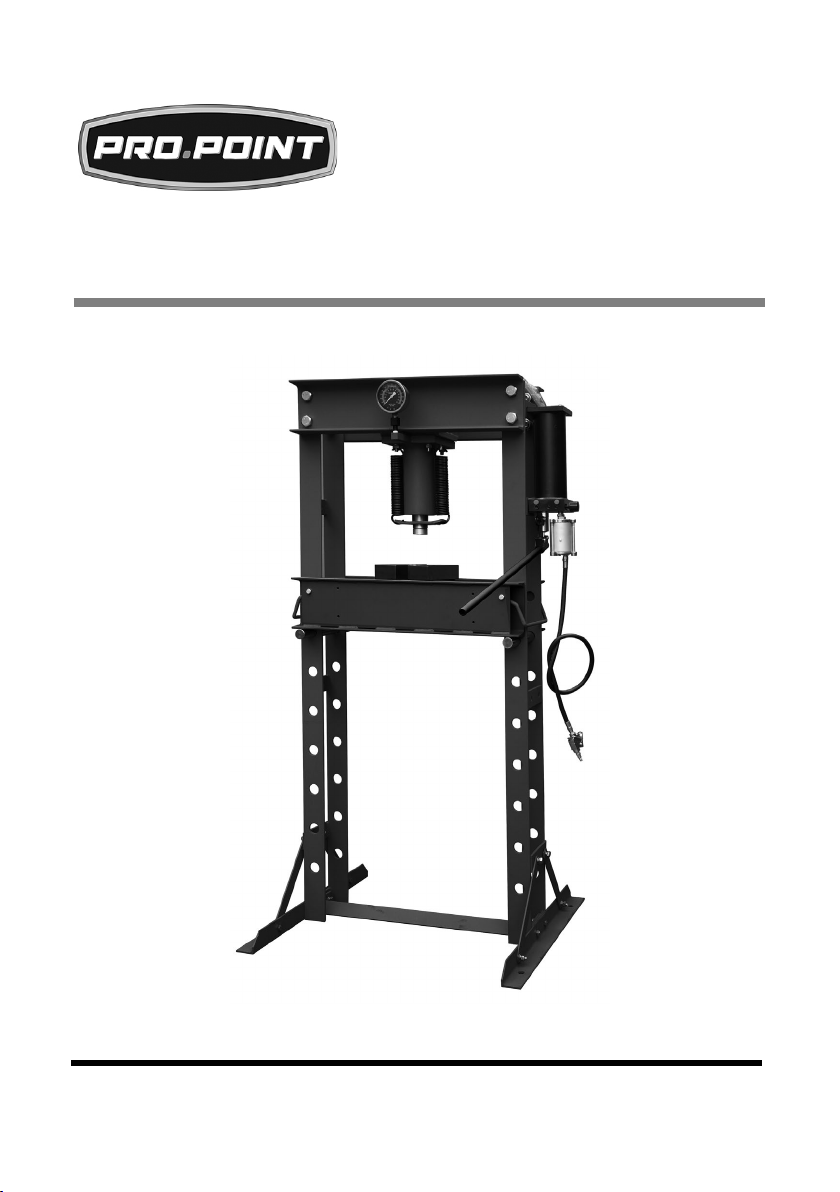

8836363 40-TON HYDRAULIC SHOP PRESS V1.0

8 For technical questions call 1-800-665-8685

2.1 The maximum load is 40 tons. Never apply excessive

force to a workpiece and always use the pressure gauge

to accurately determine the applied load.

3. Do not adjust the hydraulic system’s relief setting. The

settings are pre-set by the factory.

4. Hydraulic oil under pressure is hot and can cause a burn

injury if touched, sprayed or spilled. Allow the hydraulic

system to cool before conducting maintenance.

5. DO NOT use the press if any part is bent, broken, cracked,

leaking or otherwise damaged, or it has been subjected to

a shock load.

5.1. Hydraulic components require regular inspection.

Release all pressure from the system before you inspect

it. Replace damaged hydraulic parts with identical

manufacturer's components.

6. Do not attempt makeshift repairs to a hydraulic system.

Such repairs can fail suddenly and create a hazardous

condition.

7. A damaged or disconnected hydraulic hose under pressure

may whip around and inflict personal injury or damage the

work area. Secure the hose to a fixed or permanent

structure with clamps or cable ties.

8. Hydraulic fluid has a combustible flash point of 200°F

(93°F). Do not expose the fluid to an ignition source.

9. Change your clothing immediately if sprayed with hydraulic

fluid. Store clothing or rags contaminated with hydraulic

fluid in an approved metal safety can with a spring-closing

lid and venting designed to contain a fire.

10. Only use hydraulic fluid in the pump. Do not substitute or

mix brake fluid, or any other fluid, with the hydraulic fluid.

This can result in a pump failure and injure the user or

bystander. It may also damage the pump.