2 of 55

FF 500 CNC Commissioning Manual

1. Some generalities in advance…...................................................................................4

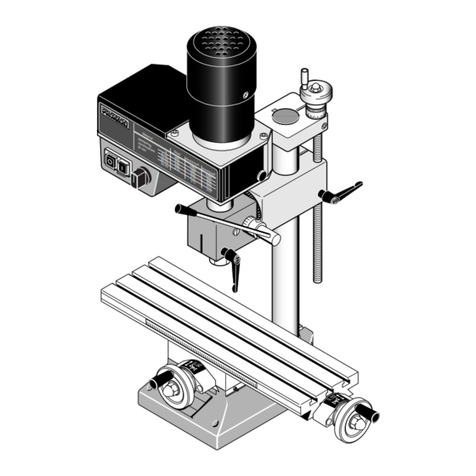

2. The technology of your FF 500 CNC at a glance .........................................................5

2.1. A short overview of the mechanics:..........................................................................5

2.2. A short overview of the electronics:..........................................................................6

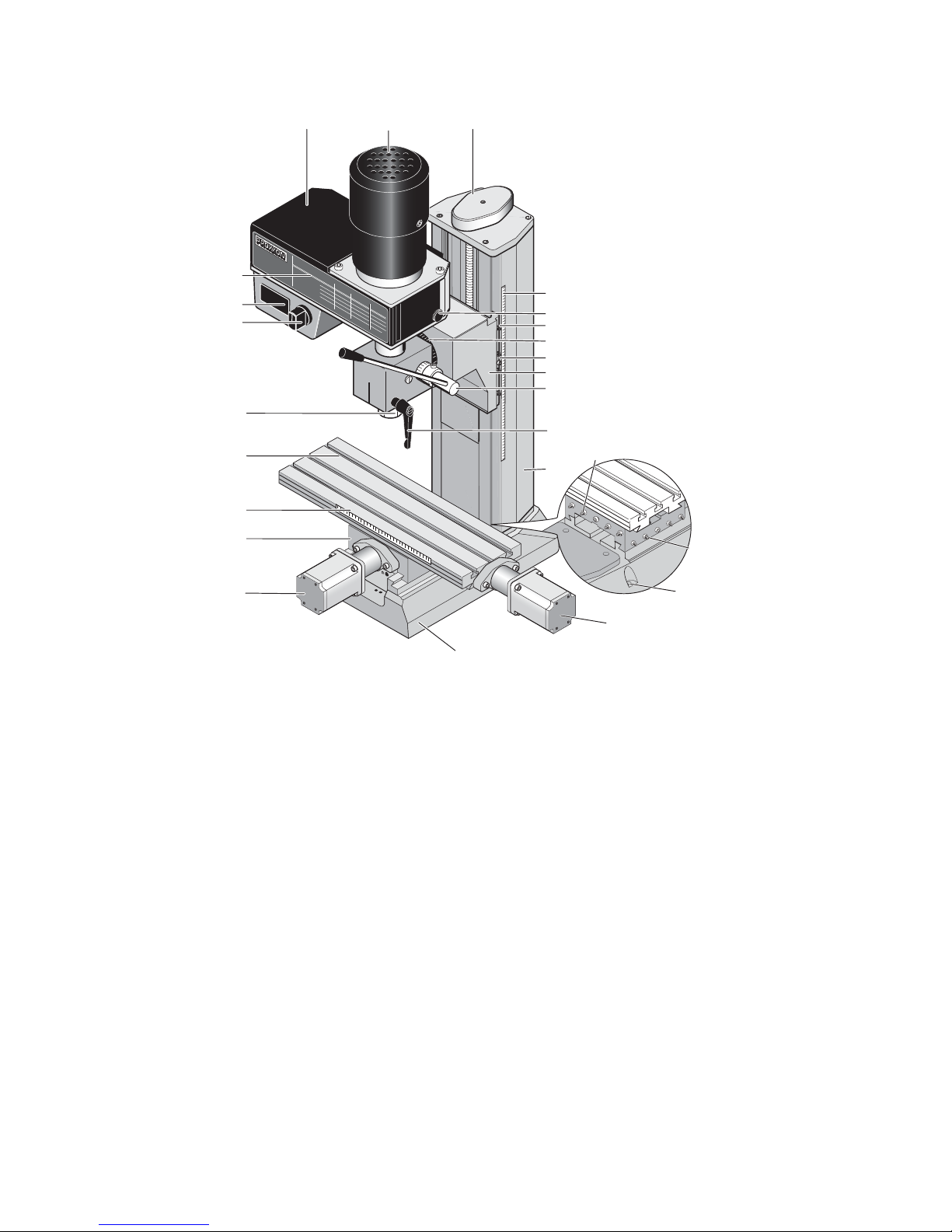

3. View of the machine with its elements..........................................................................8

4. CNC control MCS with operating elements ..................................................................9

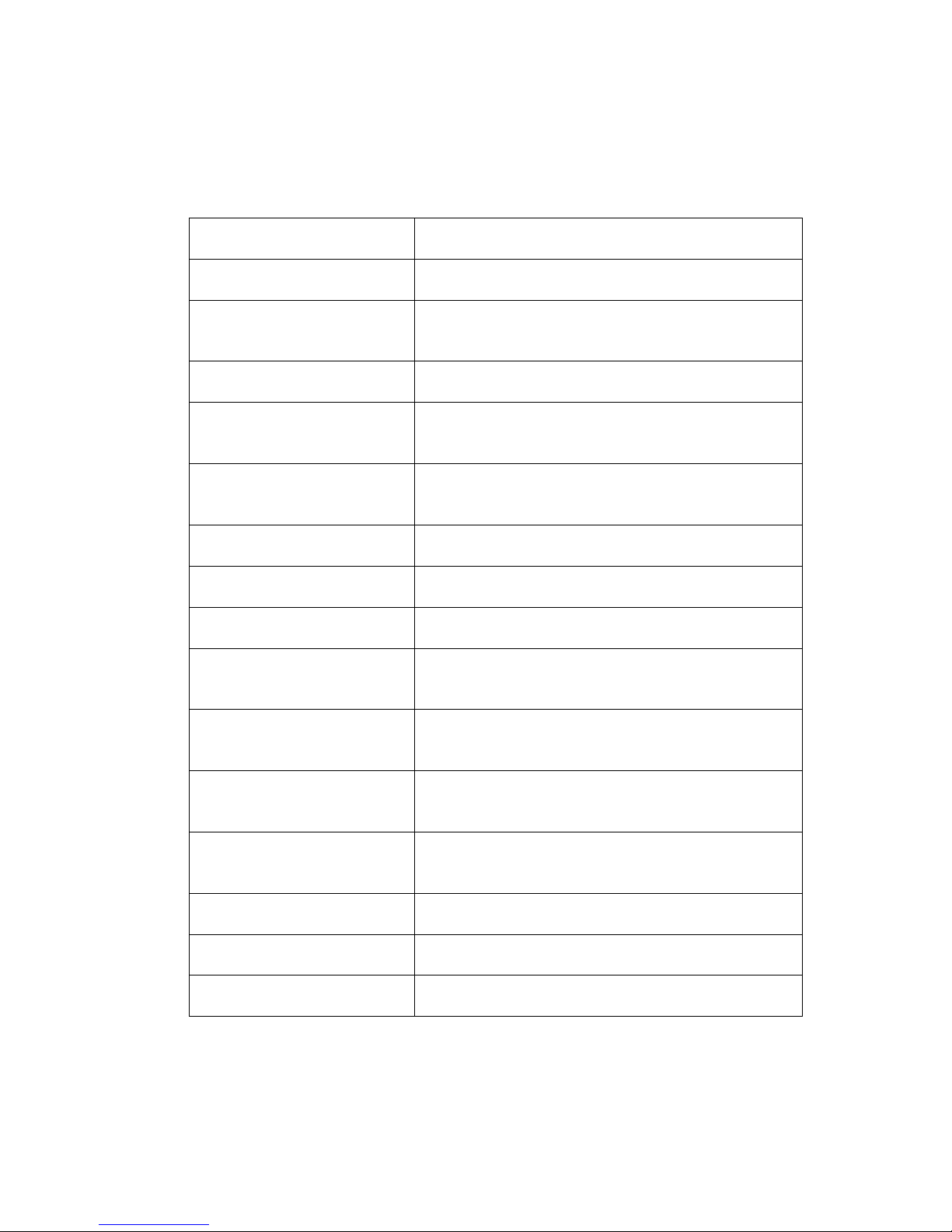

5. Technical data ............................................................................................................10

5.1. Milling machine:......................................................................................................10

5.2. Drives of the tool axes ............................................................................................11

5.3. Software and stepping motor controllers ................................................................11

5.4. Further data ............................................................................................................12

5.5. Milling cutter dimensions ........................................................................................12

6. Scope of delivery ........................................................................................................12

7. Basic tips on setting up and installing the machine ....................................................13

7.1. Unpacking and setting up the machine ..................................................................13

7.2. Connecting the cabling ...........................................................................................15

7.3. Additional connection options.................................................................................16

8. Installing the software.................................................................................................17

8.1. Minimum hardware requirements ...........................................................................17

8.2. Installation procedure .............................................................................................17

8.3. Starting the software nccad7.5 ...............................................................................18

8.4. Parameter settings .................................................................................................18

8.5. The status display at the CNC control MCS ...........................................................18

8.6. EMERGENCY stop / lock .......................................................................................19

9. The program nccad 7.5 milling ...................................................................................20

9.1. The integrated manual with the help system ..........................................................20

9.2. The structure of the "Help topics" window ..............................................................21

9.3. Search methods .....................................................................................................21

9.3.1 Contents .............................................................................................................21

9.3.2 Index...................................................................................................................21

9.3.3 Search ................................................................................................................21

9.3.4 Explanation of the icons and the Status bar .......................................................22

9.4. Online support ........................................................................................................22

10. Important note for working in practice ........................................................................23

10.1. Simple stopping of the machine and the Emergency-Off switch ........................23

10.2. Safety stop, lock .................................................................................................23

10.3. Direction of rotation switch..................................................................................23

10.4. Room EMERGENCY Off ....................................................................................23

11. First steps ...................................................................................................................24

11.1. Simple test of the machine .................................................................................24

11.2. Semi-automatic operation: Traversing the CNC axes with the cursor keys........25

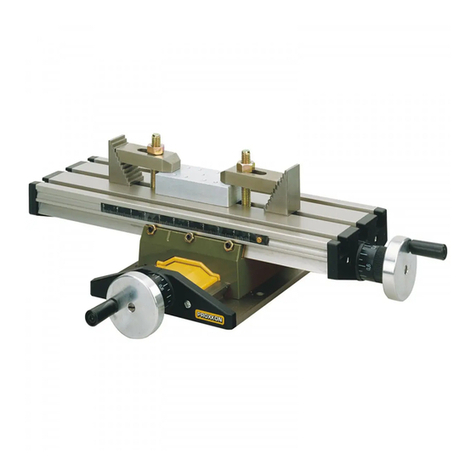

12. Working with the milling cutter....................................................................................26

12.1. General information for working with milling cutter .............................................26

12.2. Working with the drilling lever .............................................................................27

12.3. Swivelling the milling head by its own transverse axis .......................................28

12.4. Mounting the collet chucks .................................................................................28

12.5. Changing the spindle speed ...............................................................................30

12.6. Milling..................................................................................................................32

12.7. Feed:...................................................................................................................32

13. Accessories ................................................................................................................33

14. Repair, Cleaning and Maintenance ............................................................................34

14.1. In general............................................................................................................34

14.2. Replacing the drive belt ......................................................................................35

14.3. Adjusting the play of the cross table or Z carriage guides..................................36