- 3 -

Operating Instructions

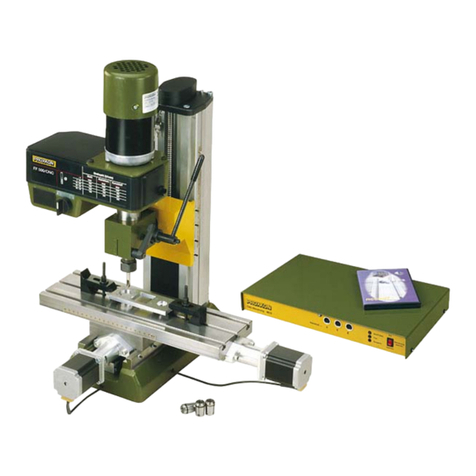

Micro Milling Machine MF 70

Dear Customer,

By purchasing your PROXXON Micro Milling Machine

MF 70, you have chosen a good-quality, high-grade

machine. The PROXXON MF 70 MICRO Milling Machine is

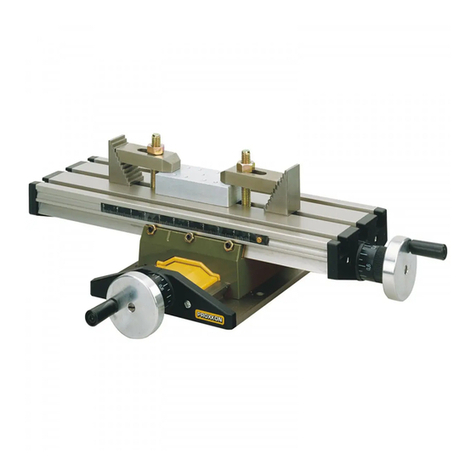

equipped with the proven KT 70 microcoordinate table.

This enables you to perform small, precise milling operati-

ons on metal, plastics or wood. In order to operate the

milling machine and the accompanying accessories safely

and correctly, please read the enclosed safety information

and operating instructions prior to operation.

This instruction manual covers:

• safety regulations

• operation and maintenance

• spare parts list

Please read carefully!

Using this instruction manual will

•make it easier for you to get used to the machine,

•help prevent faults occurring due to improper use and

•increase the service life of your machine.

Keep this instruction manual in an easily accessible place.

Only operate this machine if you are qualified to do so

and follow the guidelines in this instruction manual.

PROXXON does not accept responsibility for the safe fun-

ctioning of the machine

• if it is handled in a manner which constitutes improper

use,

• if it is used for other purposes which are not specified

in the instruction manual,

• if the safety regulations are not observed.

Warranty claims are invalid if

• the machine is incorrectly operated,

• the machine has not been sufficiently maintained.

In the interests of your safety, please always observe the

safety regulations.

Only use genuine PROXXON spare parts.

We reserve the right to make further alterations for the

purpose of technical progress.

We wish you every success with your machine.

General safety instructions:

1. REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting wren-

ches are removed from tool before turning it on.

2. KEEP WORK AREA CLEAN. Cluttered areas and ben-

ches invite accidents.

3. DON'T USE IN DANGEROUS ENVIRONMENT. Don't

use power tools in damp or wet locations, or expose

them to rain. Keep work area well lighted.

4. KEEP CHILDREN AWAY. All visitors should be kept safe

distance from work area.

5. MAKE WORKSHOP KID PROOF with padlocks, master

switches, or by removing starter keys.

6. DON'T FORCE TOOL. It will do the job better and safer

at the rate for which it was designed.

7. USE RIGHT TOOL. Don't force tool or attachment to

do a job for which it was not designed.

8. USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersi-

zed cord will cause a drop in line voltage resulting in

loss of power and overheating. Table 1 shows the cor-

rect size to use depending on cord length and name-

plate ampere rating. If in doubt, use the next heavier

gage. The smaller the gage number, the heavier the

cord.

Exception No. 1: The reference to the table and the

table itself may be omitted if a statement indicating

the appropriate gage and length is incorporated into

the instruction.

Exception No. 2: The information regarding extension

cords need not be provided for a permanently

connected tool.

9. WEAR PROPER APPAREL. Do not wear loose clo-

thing, gloves, neckties, rings, bracelets, or other jewel-

ry which may get caught in moving parts. Non-slip

footwear is recommended. Wear protective hair cover-

ing to contain long hair.

Exception: The reference to gloves may be omitted

from the instructions for a grinder.

10. ALWAYS USE SAFETY GLASSES. Also use face or

dust mask if cutting operation is dusty. Everyday

eyeglasses only have impact resistant lenses, they are

NOT safety glasses.

11. SECURE WORK. Use clamps or a vise to hold work

when practical. It's safer than using your hand and it

frees both hands to operate tool.

12. DON'T OVERREACH. Keep proper footing and

balance at all times.

13. MAINTAIN TOOLS WITH CARE. Keep tools sharp and

clean for best and safest performance. Follow instruc-

tions for lubricating and changing accessories.

14. DISCONNECT TOOLS before servicing; when chan-

ging accessories, such as blades, bits, cutters, and

the like.

15. REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure switch is in off position before plugging in.

16. USE RECOMMENDED ACCESSORIES. Consult the

owner's manual for recommended accessories. The

use of improper accessories may cause risk of injury

to persons.

17. NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped or if the cutting tool is unintentionally

contacted.

18. CHECK DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate pro-

perly and perform its intended function -- check for

alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions

that may affect its operation.

A guard or other part that is damaged should be pro-

perly repaired or replaced.

19. DIRECTION OF FEED. Feed work into a blade or cut-

ter against the direction of rotation of the blade or

cutter only.

20. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Don't leave tool until it comes to a com-

plete stop.

- 4 - - 9 -

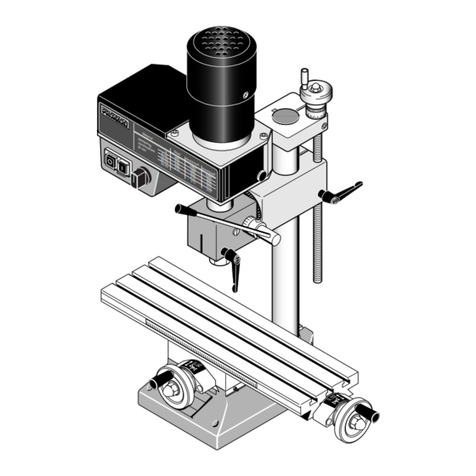

SchematicsNotes

1

19

8

6

37

15

22

14

33

13

16

7

9

5

3

5

9

7

37

32

33 14 13 22 15

20

411 30b

32

31

20

12b

2

18

34

36

17

36 35 12a

10

31

30a

21

31

16 6

8