Pulsarlube USA, Inc.

ISO9001 Registered, Single Point Lubricator Company

Pulsarlube USA, Inc

4312 DiPaolo Center. Glenview, IL 60025

TEL: 847-795-0591

FAX: 847-7895-0119

Web Site: www.pulsarlubeusa.com

Email: info@pulsarlubeusa.com

FORM

DOC#: PM-T-101

Aug, 2007(Rev05)

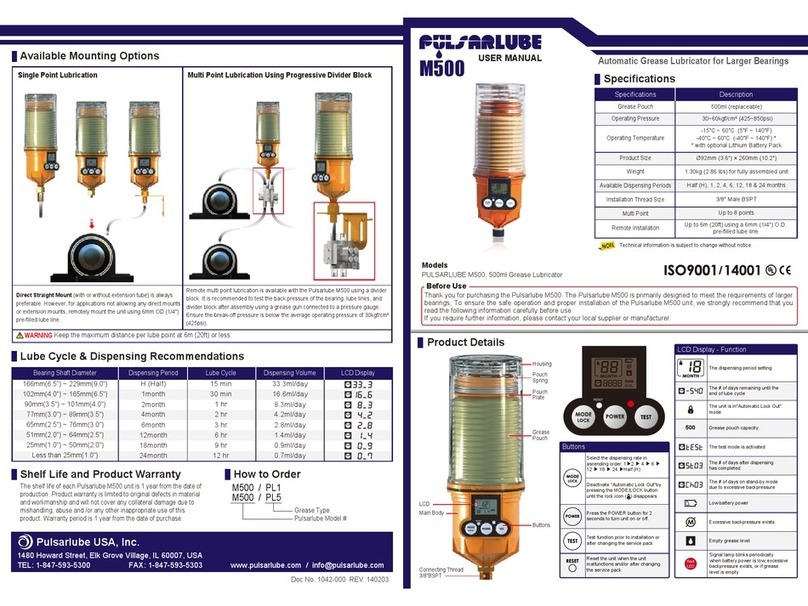

Disposable 500cc Service pack

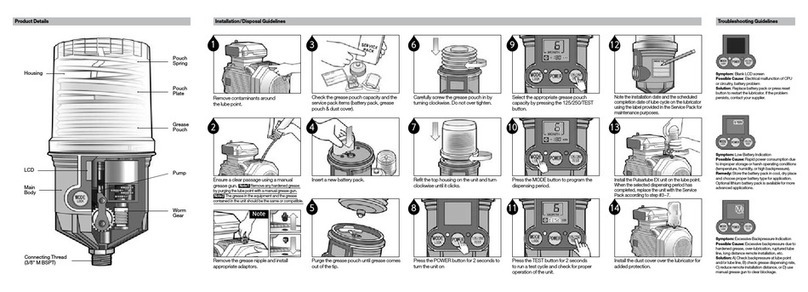

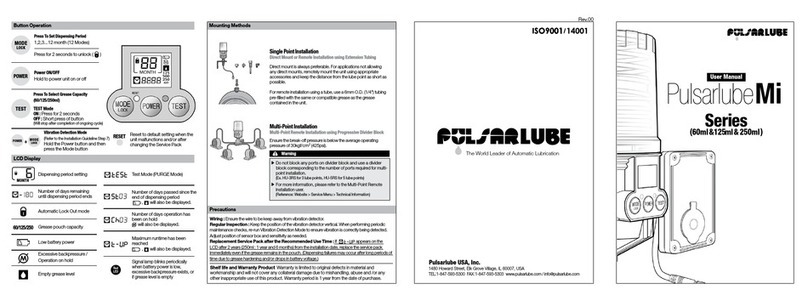

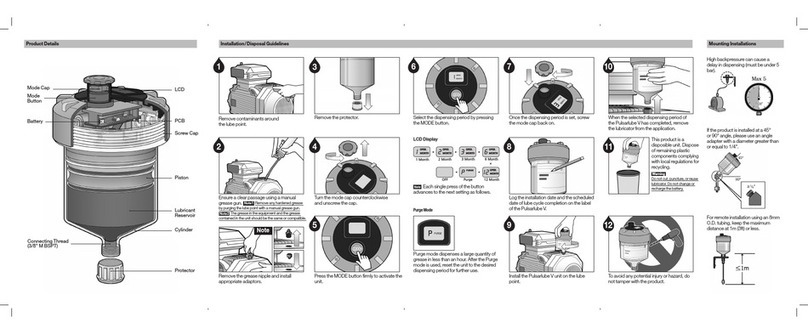

Initial Installation Procedure.

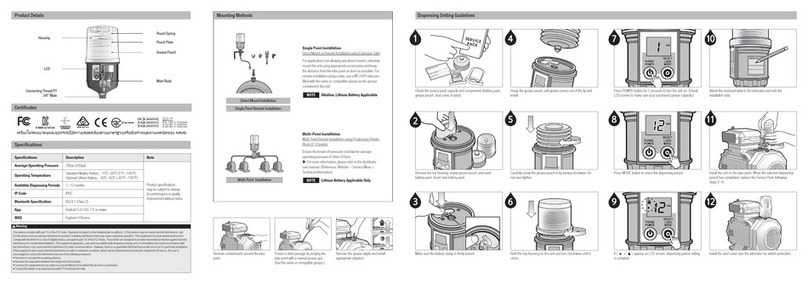

1. Make sure the lubrication point is manually lubricated with a grease gun to ensure that the bearing has a clear

passageway before installing your 500cc unit. It is recommended that this procedure be conducted using

either the same or a compatible lubricant with what is contained in the grease cartridge of the Pulsarlube M

500cc unit

2. If any doubts exist in regards to a clear lubrication flow, test the backpressure of the bearing with a grease

gun connected to a pressure gauge. Ensure that the break – off pressure is below 500 psi (approx. 35 kg-

f/cm2: 34.5 bar). Note that it is always desirable to keep the constant delivery pressure as low as possible.

3. Insert the Battery Pack into the battery compartment of the main unit. (Make sure that the battery is locked in

place after insertion by turning the metal clip on top). Place the pointed open end of the Top Housing over the

lubricators’ top check valve and turn Top Housing clockwise until you hear the Top Housing “click”.

4. Open Top Housing Cap and put 500cc grease pouch and replace Top Housing Cap.

5. Turn the Pulsarlube ML500 unit ON by depressing the Power Button for 2 seconds. To confirm that the LCD

is working, make sure that the Red LED blinks once as soon as you press the “Power” button. The unit is

working as long as the LCD displays information.

6. To test that the unit is functioning properly, simply follow the TEST MODE PROCEDURE:

• Press the Power button first (for 2 seconds) to turn on unit, and then press the TEST button for 2

seconds. The unit will begin start dispensing grease. The unit will operate continuously in Purge mode

and go through an entire cycle of (approximately 2 min).

• To deactivate the TEST MODE FUNCTION, press the TEST button again. The unit will stop testing within

the next 20 seconds.

• If the unit is malfunctioning or if you encounter any difficulty, please refer to the troubleshooting guide.

7. Depress the MODE button to set the dispensing rate. Each time the MODE button is depressed,

the dispensing rate changes in ascending order

i.e. 1►2►4►6►12►18►24►H. Note: (H = Half month.)

Note: If you are unable to program a setting and a lock icon is displayed, press the mode button for

2 seconds until the lock icon disappears. Program your lubricator. The unit will automatically

lock 60 seconds after you stop pressing any of the 3 programming buttons.