If ( + ) appear on LCD screen, dispensing period setting

is complete.

Press MODE button to select the dispensing period.

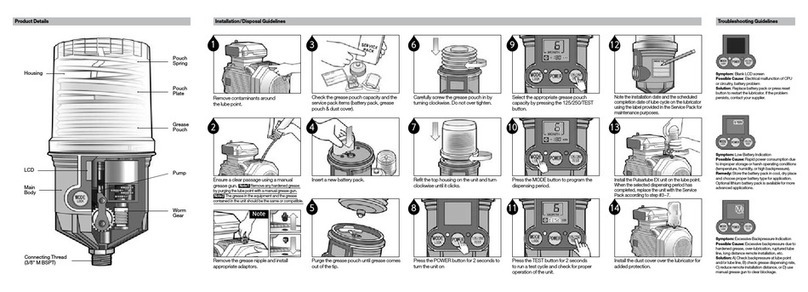

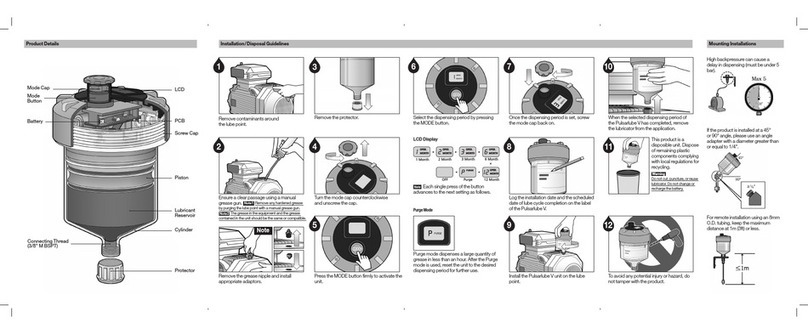

Remove contaminants around the lube

point.

Ensure a clear passage by purging the

lube point with a manual grease gun.

(Use the same or compatible grease.)

Remove the grease nipple and install

appropriate adaptors.

Carefully screw the grease pouch in by turning clockwise. Do

not over tighten.

Install the unit on the lube point. When the selected dispensing

period has completed, replace the Service Pack following

steps 2~6.

Purge the grease pouch until grease comes out of the tip and

install.

Press POWER button for 3 seconds to turn the unit on. (Check

LCD screen to make sure your purchased grease capacity.)

Attach the enclosed label to the lubricator and note the

installation date.

Dispensing Setting Guidelines

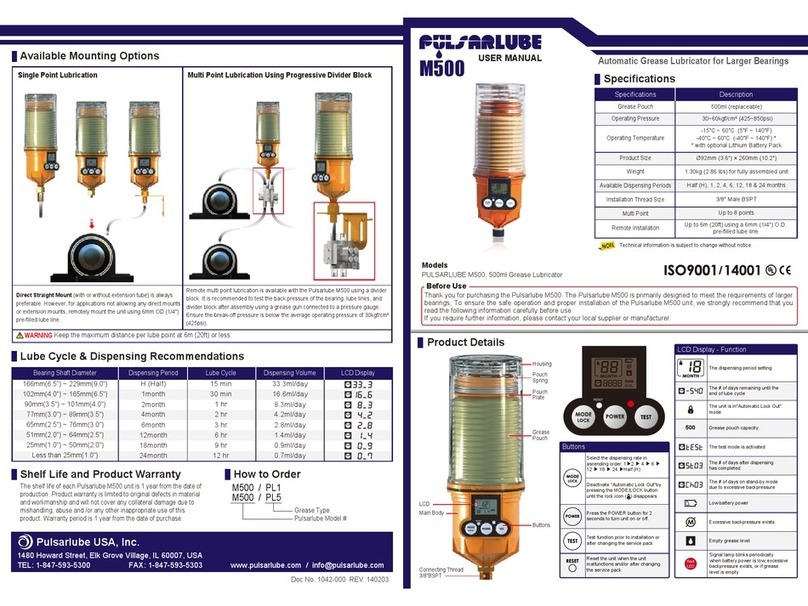

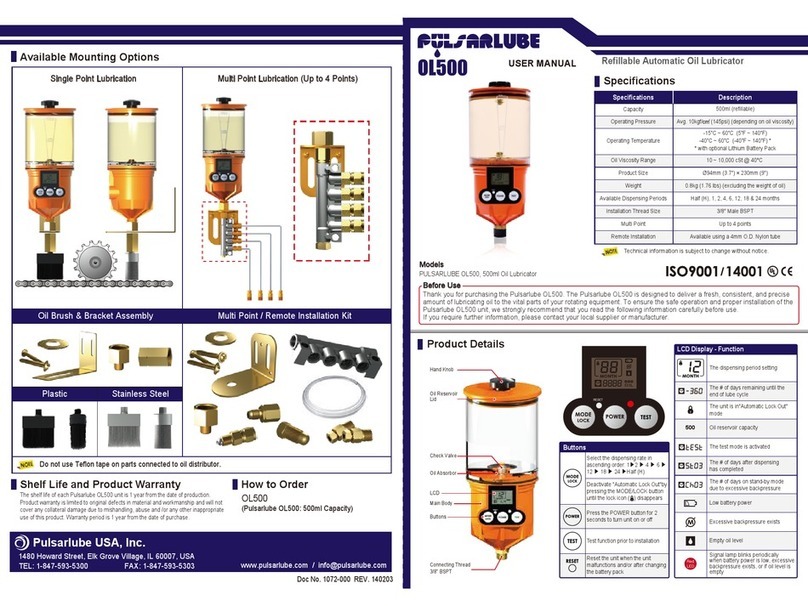

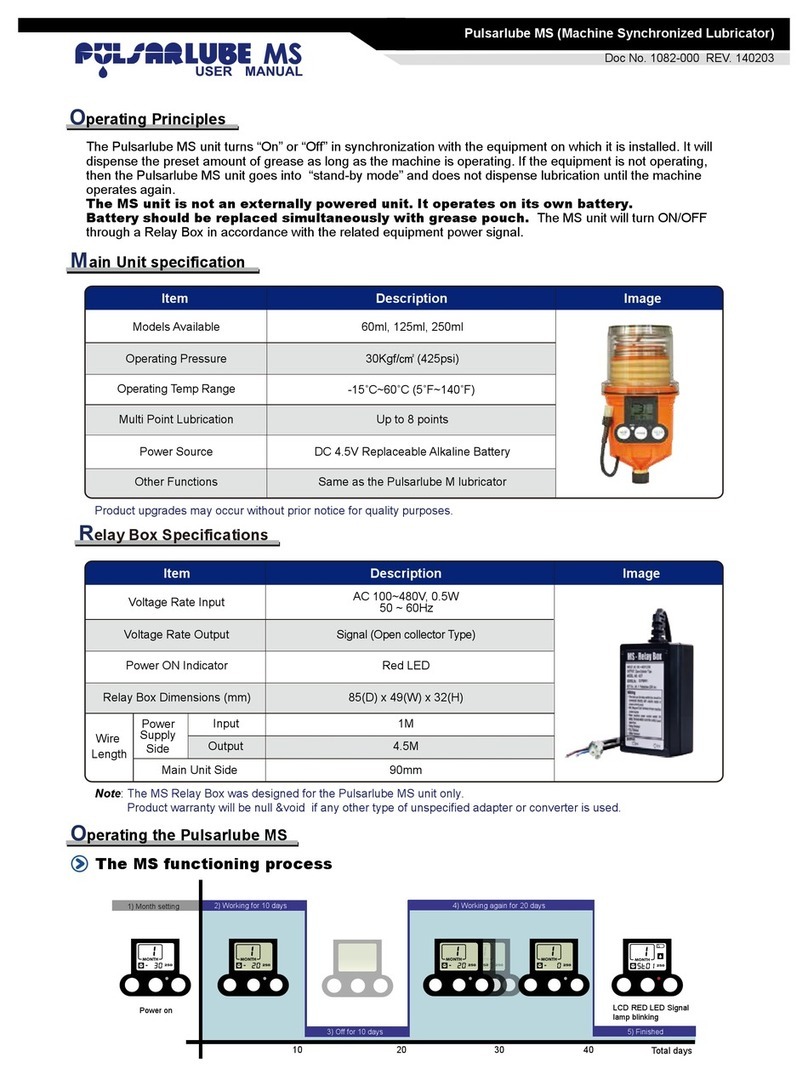

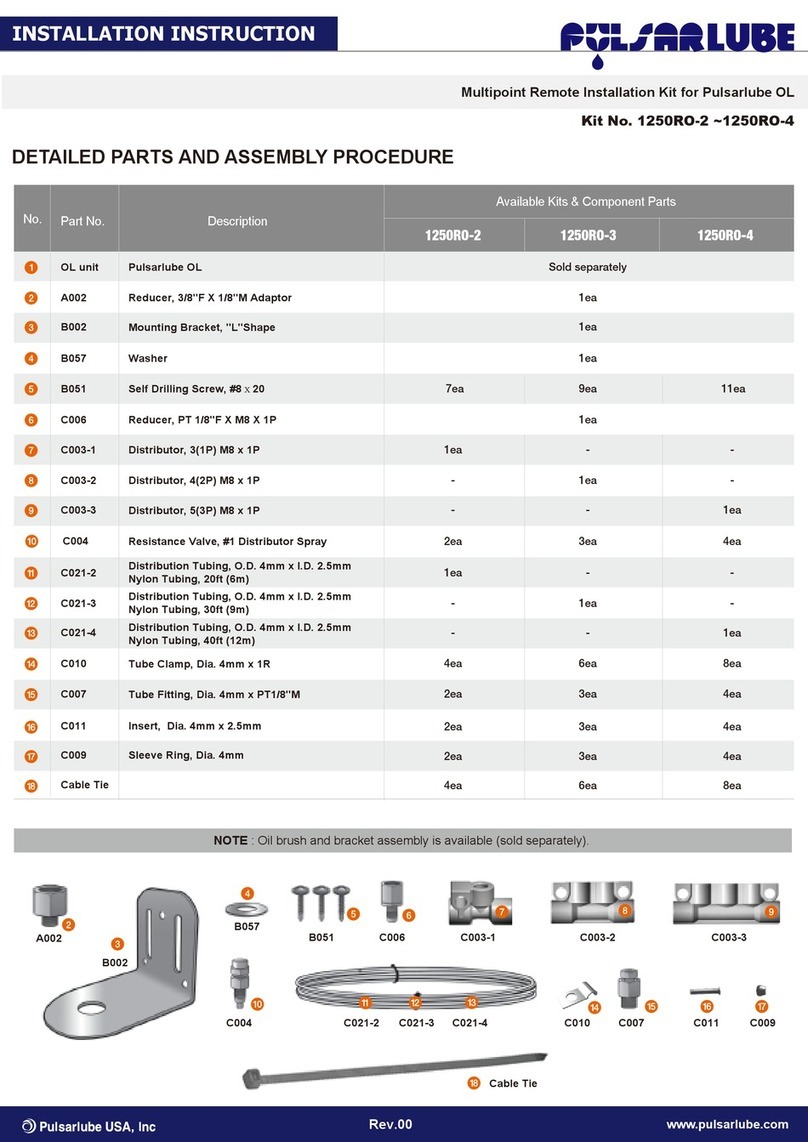

Product Details

Specifications

Warning

Remove the top housing, empty grease pouch, and used

battery pack. Insert new battery pack.

Check the service pack capacity and components (battery pack,

grease pouch, dust cover, & label).

Housing

Pouch Spring

Pouch Plate

Grease Pouch

Main Body

LCD

Connecting Thread PT

3/8" Male

14

3 6

7

912

Ret the top housing on the unit and turn clockwise until it

clicks.

Install the dust cover over the lubricator for added protection.

Make sure the battery clamp is rmly locked.

5 8 11

2

10

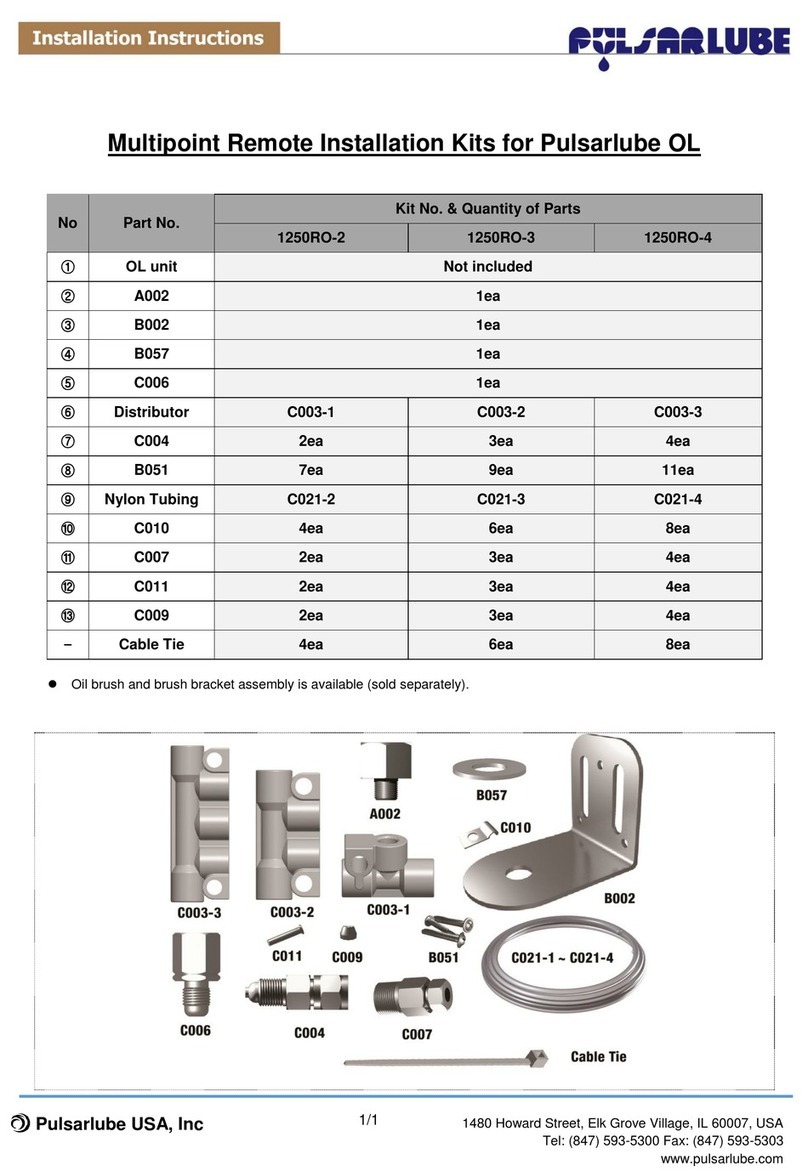

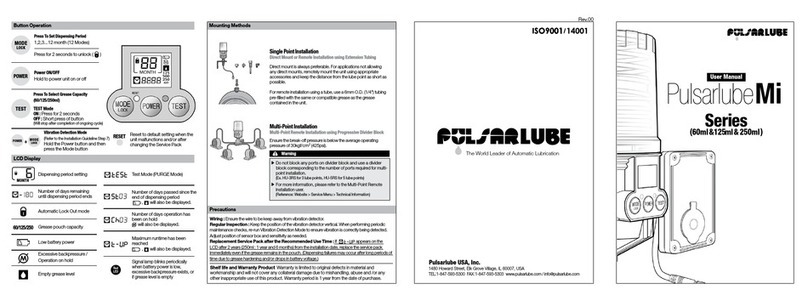

Mounting Methods

Direct Mount Installation

Single Point Remote Installation

Multi-Point Installation

Single Point Installation

Direct Mount or Remote Installation using Extension Tube

For applications not allowing any direct mounts, remotely

mount the unit using appropriate accessories and keep

the distance from the lube point as short as possible. For

remote installation using a tube, use a Ø6 (1/4") tube pre-

lled with the same or compatible grease as the grease

contained in the unit.

Multi-Point Installation

Multi-Point Remote Installation using Progressive Divider

Block (2~8 points)

Ensure the break-off pressure is below the average

operating pressure of 30bar (435psi).

▶ For more information, please refer to the distributor

user manual. (Reference: Website > Service Menu >

Technical Information)

NOTE

NOTE

Alkaline, Lithium Battery Applicable

Lithium Battery Applicable Only

Specications Description Note

Average Operating Pressure 30bar (435psi)

Product specications

may be subject to change

for performance or quality

improvement without notice.

Operating Temperature Standard Alkaline Battery : -15˚C~60˚C (5°F~140°F)

Optional Lithium Battery : -40˚C~60˚C (-40°F~140°F)

Available Dispensing Periods 1~12 months

IP Code IP65

Bluetooth Specication BLE4.1 (Class 2)

App Android 5.0 / iOS 7.0 or newer

WAS Explorer / Chrome

Certificates

KLT Co., Ltd.

型号(Model):

BT60

CMIIT ID: 2019DJ0846

BT120 CMIIT ID: 2019DJ0847

BT240 CMIIT ID: 2019DJ1090

เครื่องโทรคมนาคมและอุปกรณ์นี้มีความสอดคล้องตามมาตรฐานหรือข้อกําหนดทางเทคนิคของ กสทช.

TA-2 019/512 7

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions: (1)This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation. This equipment has been tested and found to

comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to correct the interference by one of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.