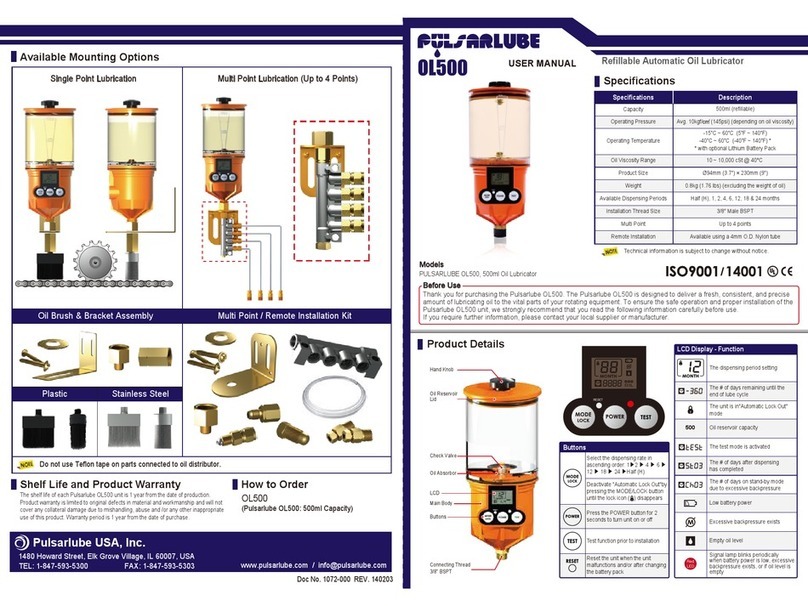

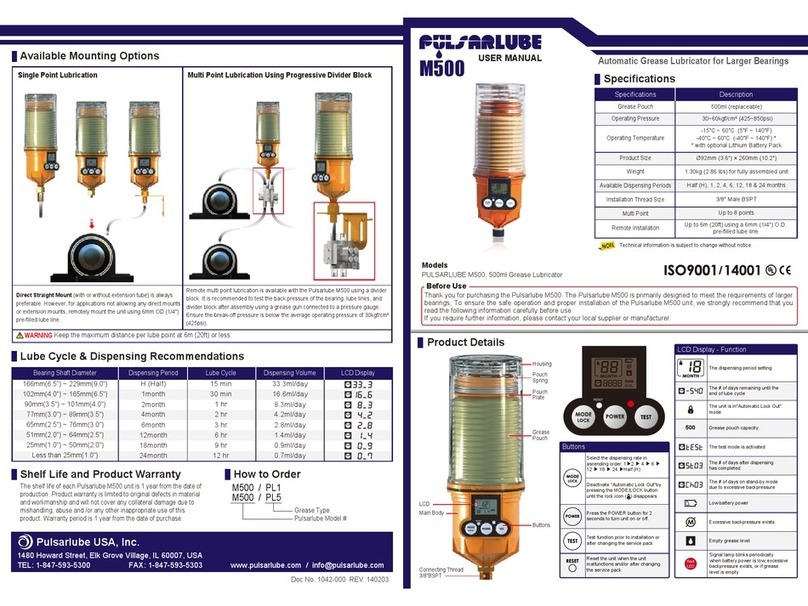

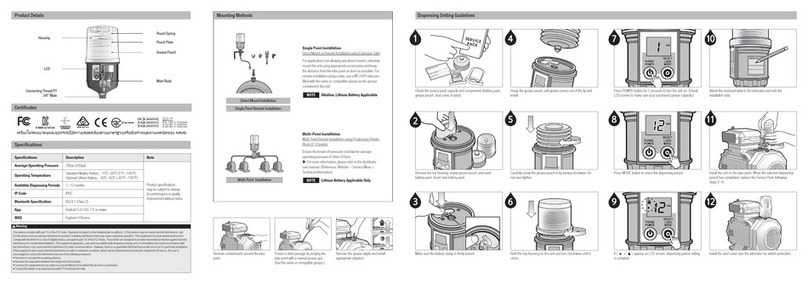

Available Mounting Options

Direct Straight/Angle Mount (with or without extension tube) is

always preferable. However, for applications not allowing any

direct mounts or extension mounts, remotely mount the unit

using a 6mm O.D. (1/4") pre-filled lube line.

WARNING

Keep the maximum distance per lube point at 6m (20ft) or less.

Single Point Lubrication Multi Point Lubrication Using Progressive Divider Block

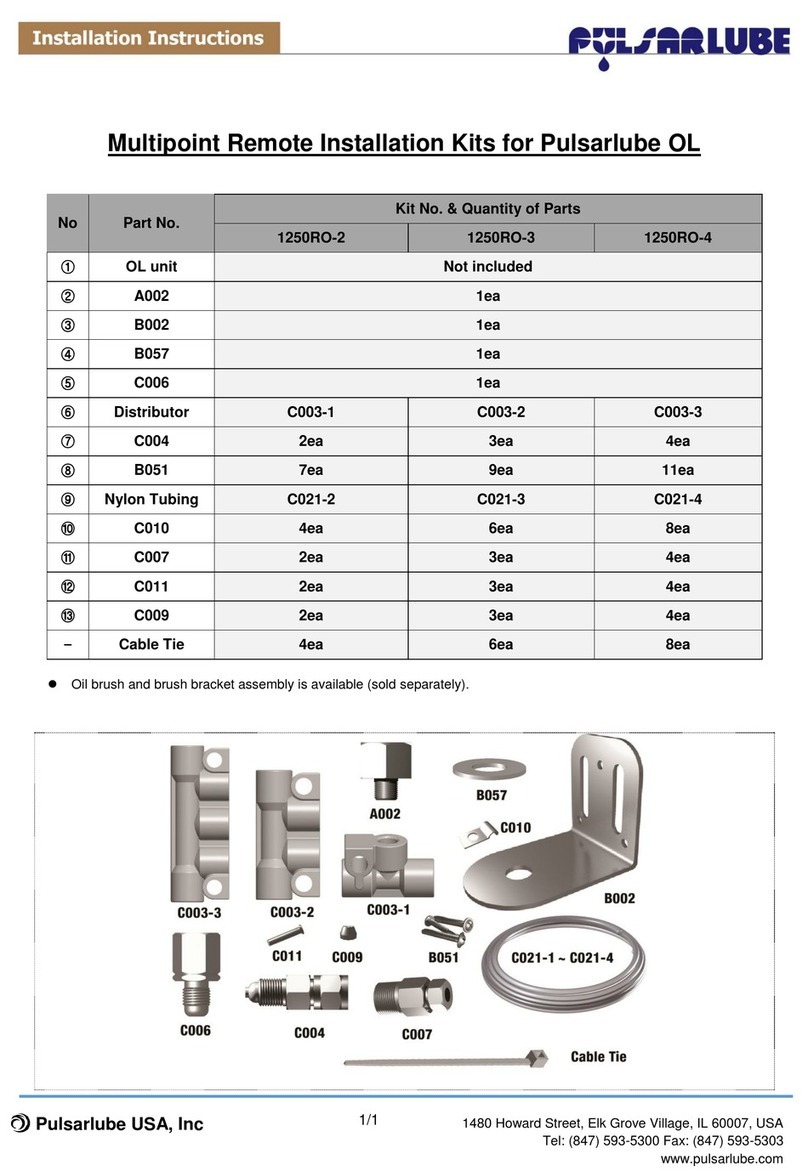

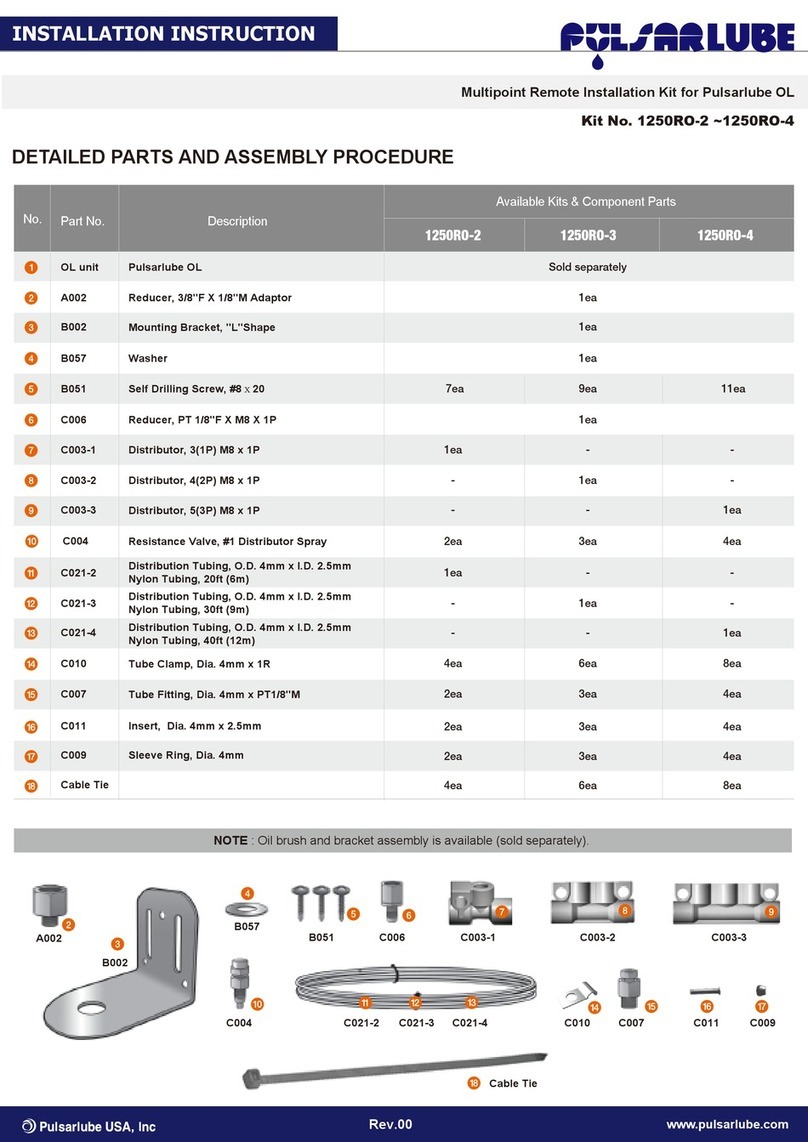

Installation parts for Multi Point Lubrication

Mounting Bracket Assembly Extension Tube Progressive Divider Block

Remote multi point lubrication is available with the Pulsarlube M using

a divider block. It is recommended to test the back pressure of the bearing,

lube lines, and divider block after assembly using a grease gun connected to

a pressure gauge. Ensure the break-off pressure is below the average operating

pressure of 30kgf/㎠(425psi).

High Performance Automac Grease Lubricator

PULSARLUBE M 125/250cc Grease Lubricator

Models

Specifications

Grease Pouch

Installation Thread Size

Available Dispensing Periods

Multi Point

Weight

Product Size

Remote Installation

125 / 250cc (replaceable)

-15˚C ~ 60˚C (5˚F ~ 140˚F)

-40˚C ~ 60˚C (-40˚F ~ 140˚F) *

30~60kgf/㎠ (425~850psi)

3/8" Male BSPT

Up to 8 points

Half (H), 1, 2, 3, 6 & 12 months

125cc: Ø91mm (3.6") × 183mm (7.2")

125cc: 860g (1.89 lb)

250cc: 1,050g (2.31 lb)

250cc: Ø91mm (3.6") × 210mm (8.2")

Up to 6m (20ft) using a 6mm (1/4") O.D.

pre-filled lube line

Operating Pressure

Operating Temperature

Specifications Description

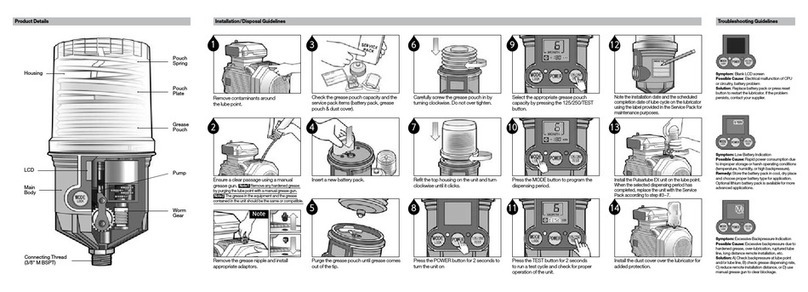

Product Details

How to Order

Technical information is subject to change without notice.

Before Use

Shelf Life and Product Warranty

KLT125 / PL1

KLT250 / PL1

Pulsarlube Model #

(KLT125: 125cc, KLT250: 250cc)

Grease Type

Pulsarlube USA, Inc.

4312 Di Paolo Center, Glenview, IL 60025, USA

Doc No. 1042-000 REV. 120600

TEL: 1-847-795-0591 FAX: 1-847-795-0119

The shelf life of each Pulsarlube M unit is 1 year from the date of production.

Product warranty is limited to original defects in material and workmanship

and will not cover any collateral damage due to mishandling, abuse and /or any

other inappropriate use of this product. Warranty period is 1 year from the date

of purchase.

/

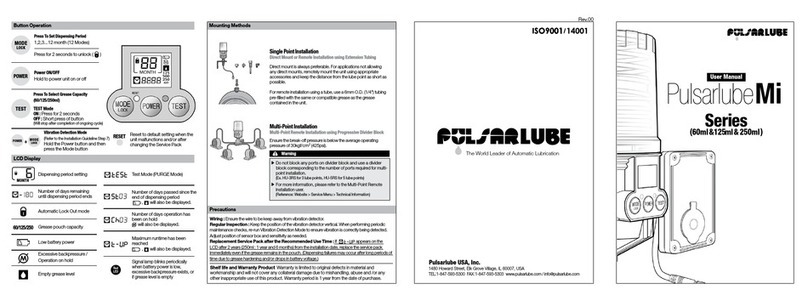

Deactivate "Automatic Lock Out"by

pressing the MODE/LOCK button

until the lock icon ( ) disappears

125 / 250

Thank you for purchasing the Pulsarlube M, the electromechanical automatic grease lubricator from Pulsarlube USA, Inc.

To ensure the safe operation and proper installation of the Pulsarlube M unit, we strongly recommend that you read the

following information carefully before use.

If you require further information, please contact your local supplier or manufacturer.

* with optional Lithium Battery Pack

The dispensing period setting

The # of days remaining until the end

of lube cycle

The unit is in"Automatic Lock Out"

mode

Selected grease pouch capacity

The test mode is activated

Select the dispensing rate in

ascending order: 1▶2 ▶ 3 ▶ 6 ▶

12 ▶ Half (H)

Press the POWER button for 2

seconds to turn unit on or off

Select the volume of grease pouch

Run a test cycle by pressing the

TEST button for two seconds

Reset the unit when the unit

malfunctions and/or after changing

the service pack

The # of days after dispensing has

completed

The # of days on stand-by mode

due to excessive backpressure

Low battery power

Excessive backpressure exists

Empty grease level

Signal lamp blinks periodically

when battery power is low, excessive

backpressure exists, or if grease

level is empty

250

125

OIL

Buttons

LCD Display - Function

Pouch

Spring

Pouch

Plate

Grease

Pouch

Motor

Gear

Set

Worm

Gear

Connecting Thread

3/8"BSPT

Piston

LCD

Main Body

Housing

Push-in One-touch

Fitting

Empty & Pre-filled Nylon

Tubing