500

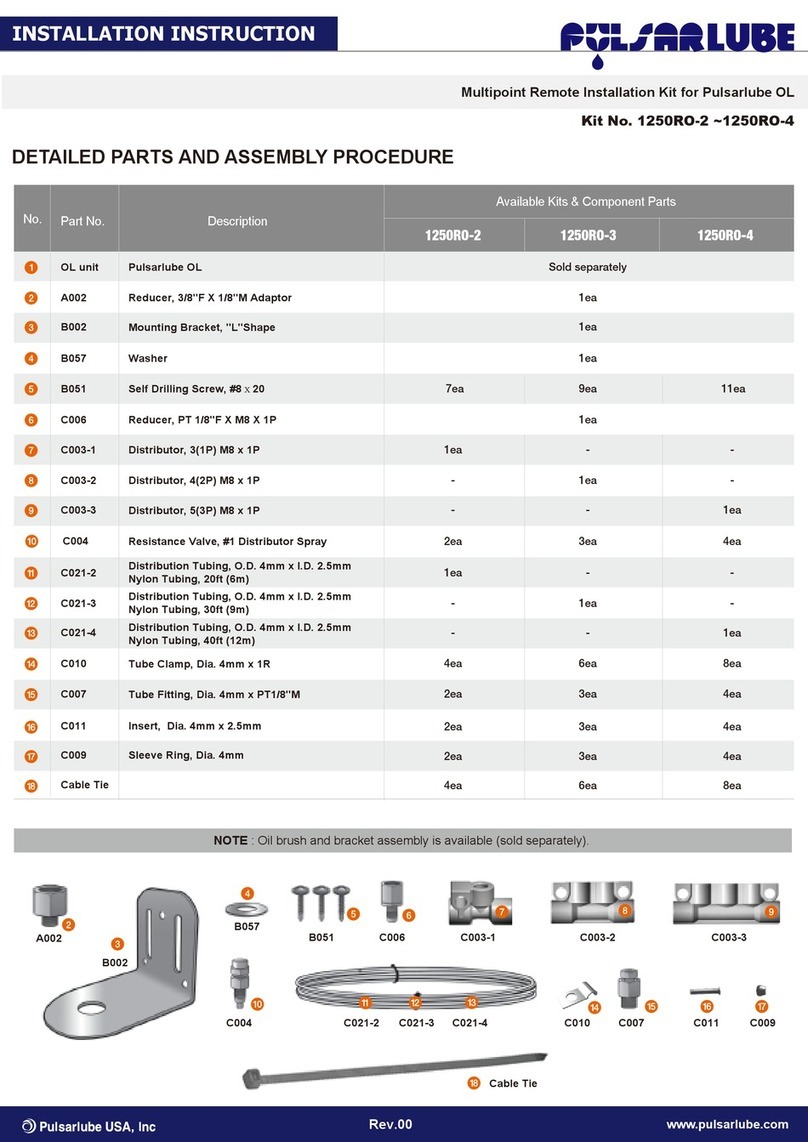

Installation Instructions

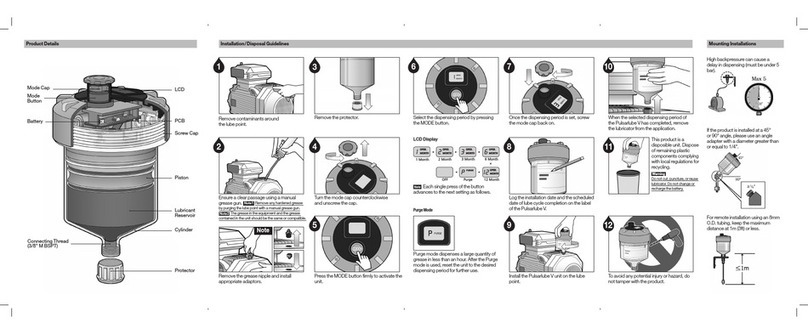

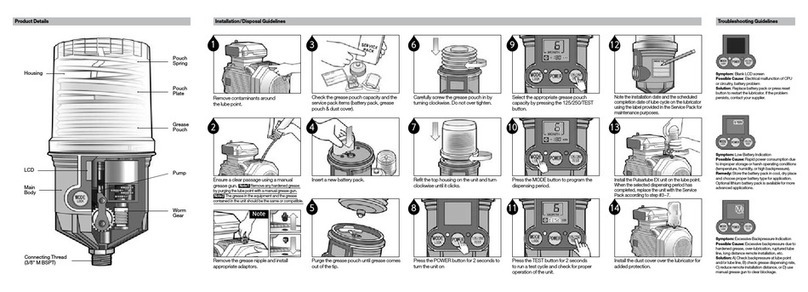

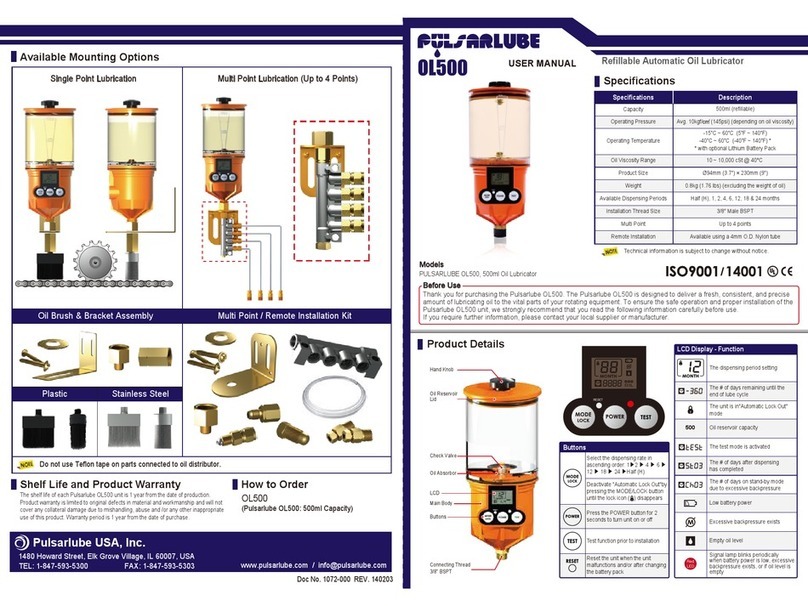

For Completely Assembled Pulsarlube M500 Unit - Initial Installation

Before installation of the Pulsarlube M500 unit, remove contaminants around the lube

point and ensure a clear passage by purging the lube point with a manual grease gun.

Remove the grease nipple and check for hardened grease at the bearing lube point.

If hardened grease exists, clean the lube point before mounting the Pulsarlube M500

unit on the bearing.

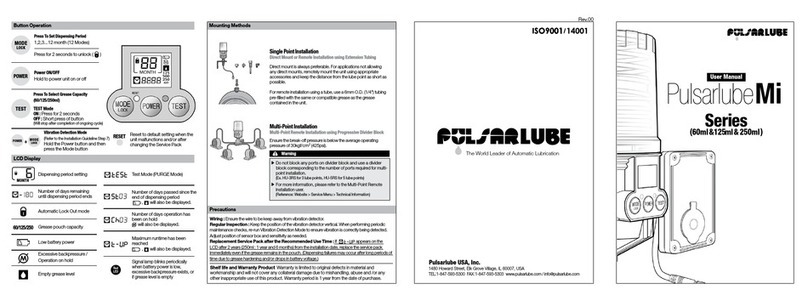

Press the MODE button to program the dispensing period.

Each time the MODE button is pressed, the dispensing period changes in ascending

order: 1▶2 ▶4 ▶6 ▶12 ▶18 ▶24 ▶H (H=Half month)

1

2

3

4

5

Install the Pulsarlube M500 unit on the lube point using appropriate adapters and

accessories as needed. Make sure that adapters and accessories are firmly tighten-

ed.

The installation date and the scheduled date of lube cycle completion should be

logged for maintenance purposes.

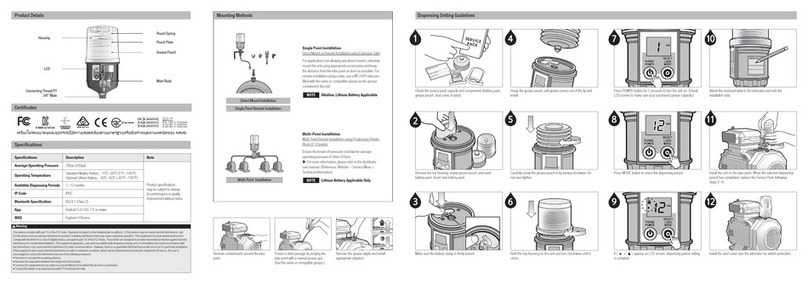

Quick Reference for Service Pack Installation

12 3 4 5

If the Pulsarlube M500 unit is provided with a replaceable service pack, the following procedure is required before step #2 of above.

For complete service pack installation instruction, please refer to the Service Pack user manual, step #2~6 in the section of "How to

Replace a Service Pack".

Service Pack Installation

Turn the Pulsarlube M500 unit ON by depressing the POWER button for 2 seconds.

The red LED blinks once as soon as the POWER button is depressed.

Press the TEST button for 2 seconds to run a test cycle.

The unit will start to dispense grease and operate continuously in purge / test mode.

This process will last approximately 2 minutes to ensure every function of the

lubricator is working properly.

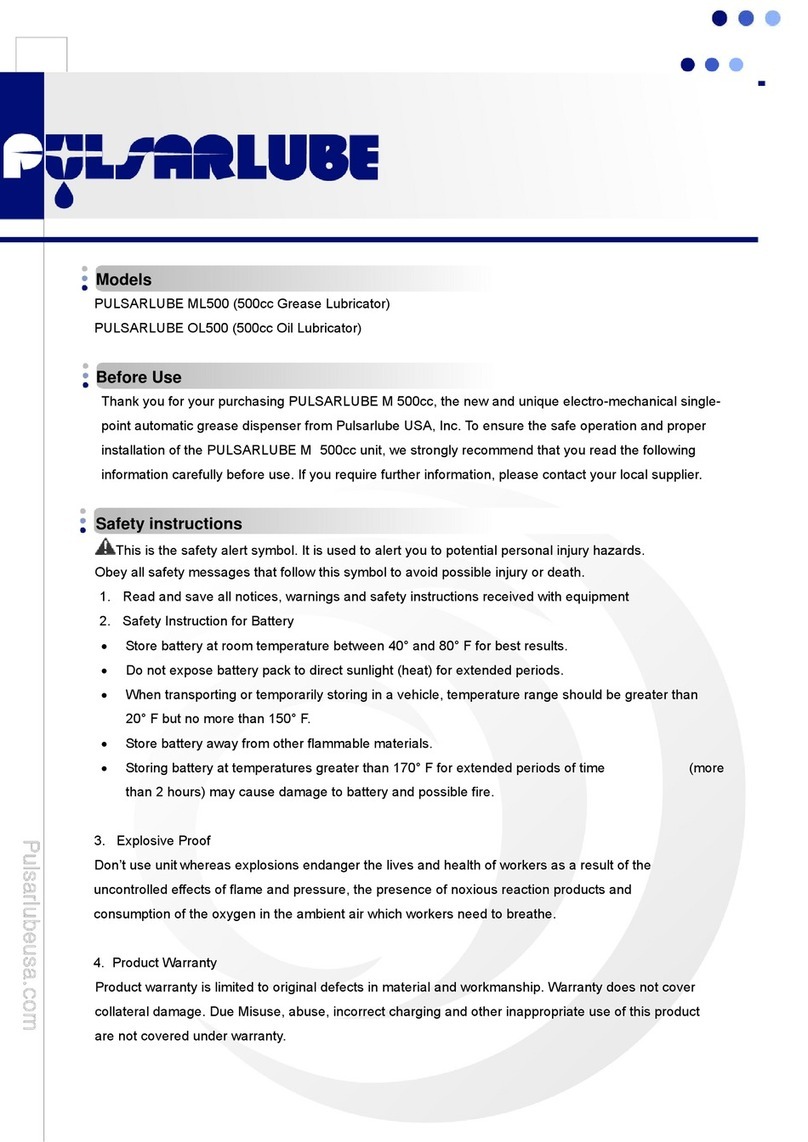

Troubleshooting Guideline

WARNING

Symptom Possible Cause of TroubleLCD Display Troubleshooting Steps

ㆍElectrical malfunction of CPU or circuitry

ㆍContact problem (open circuit) at buttons in

control panel

ㆍElectrical malfunction of CPU or circuitry

ㆍBattery pack installed incorrectly

ㆍFaulty or damaged battery pack

ㆍOld battery pack was not replaced

1. Make sure the battery pack is installed correctly

2. Replace battery pack

Contact your local supplier or manufacturer for either repair

or replacement

3. Contact your local supplier or manufacturer for either

repair or replacement

ㆍThe battery pack must be replaced together with each

grease pouch replacement

ㆍKeep battery pack stored in a cool, dry place to prevent

damage

ㆍExpired battery pack

ㆍExtreme storage conditions (temperature or

humidity)

ㆍFaulty or damaged battery pack

ㆍExtreme operating conditions

1. Ensure operating environment meets requirements

2. Replace battery pack

ㆍOver lubrication

ㆍHigh backpressure in lube line due to hardened

grease, ruptured lube line, long distance remote

installation, etc.

ㆍLow battery power due to extreme operating

conditions

ㆍGrease pouch incorrectly fitted

ㆍGrease pouch empty

ㆍGrease hardens due to cold temperature or

high oil separation

ㆍInstall and secure grease pouch correctly

ㆍReplace grease pouch and battery pack

ㆍUse appropriate quality grease for operating

environment

Unit Won't

operate

Low Battery

Indication

Excessive backpressure exists due to:

If the lubricator reaches the end of its cycle and

there is lubricant still remaining in the grease pack

Unit Won't

Dispense

Grease

Normal

Normal

Blank

Screen

ㆍCheck for grease hardening within the grease

pack or in the lube line.

unlock

1. Deactivate Auto Lock

3. Check if grease is

dispensing

2. Run test mode

If the issue is not solved, refer to

the steps below.

If after running test mode is

still present:

ㆍUninstall the lubricator from the bearing or remote

installation kit

ㆍResolve the cause of backpressure

before reinstalling lubricator

unlock

ㆍReplace battery pack

ㆍCheck backpressure at lube point

and/or lube line

ㆍCheck grease dispensing rate

ㆍReduce remote installation distance

ㆍUse a lithium battery pack in

extreme environments

If after running test mode is

no longer present, it is okay to

reinstall the lubricator.

To check for hardening of the grease.

1. Purge hardened grease out of

grease pack, then re-install.

2. Run the test mode and ensure that

the lubricator is dispensing properly.

Install the unit onto lube point.

3. If the lubricator is still not dispensing;

replace with new grease pack.