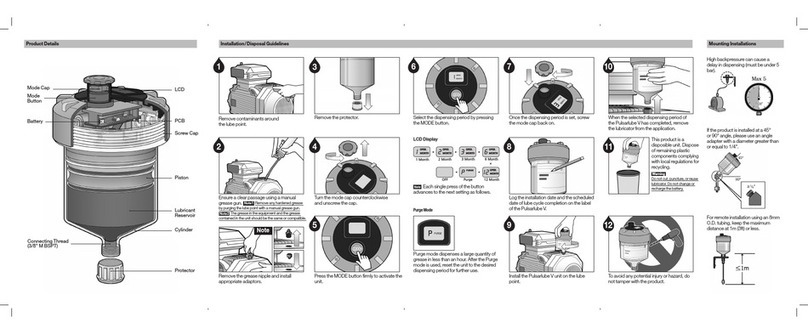

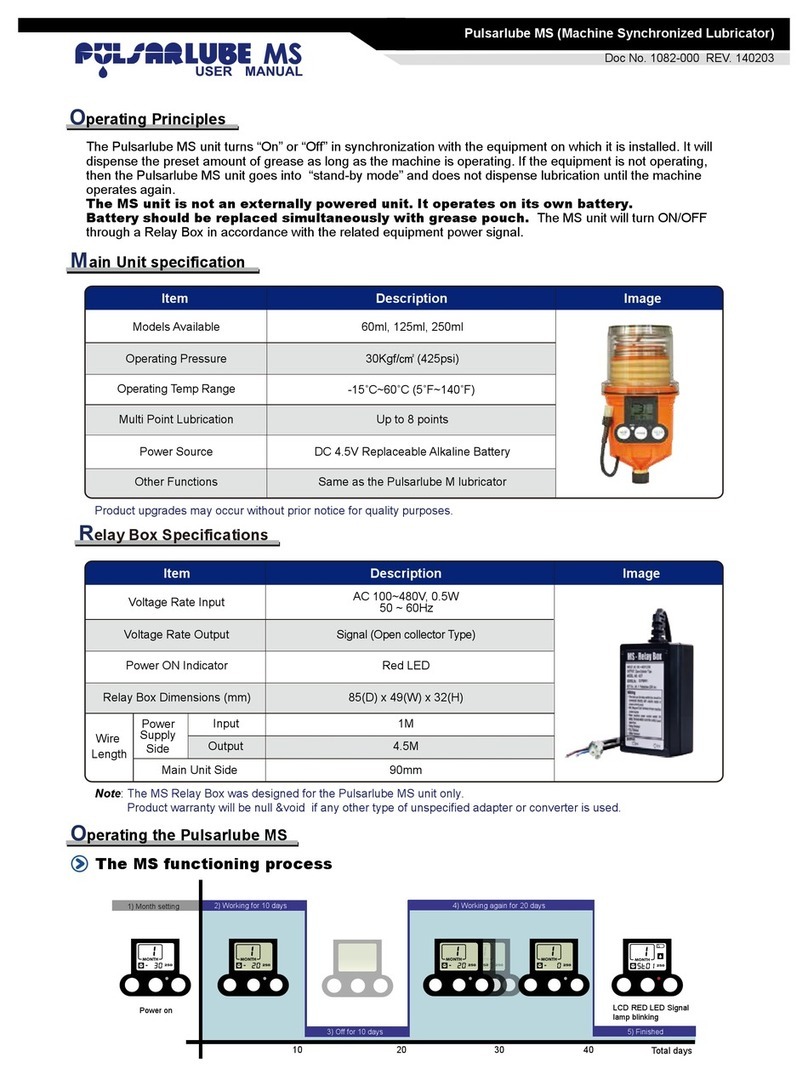

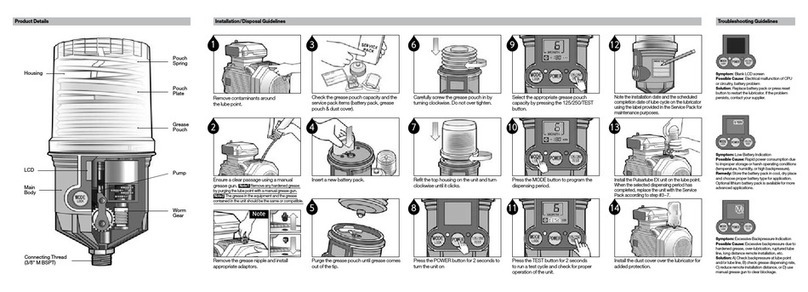

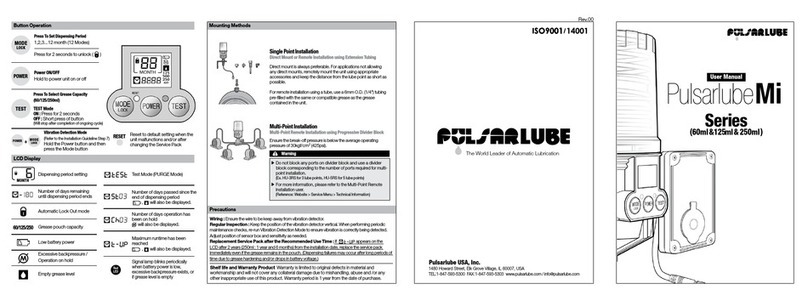

Installation Instructions - For First Installation

Press the MODE button to program the

dispensing period. Each time the MODE

button is pressed, the dispensing period

changes in ascending order:

1▶2 ▶4 ▶6 ▶12 ▶18 ▶24 ▶

H (H=Half month)

How to Replace a Battery Pack

1 2 3 4

Troubleshooting Guideline

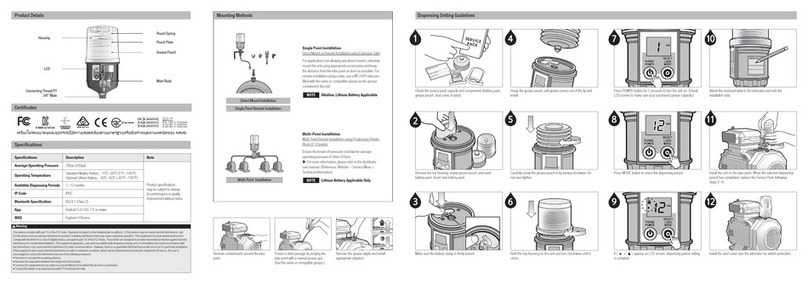

Dispensing Period Lube Cycle Dispensing Volume LCD Display

16.6ml/day

33.3ml/dayH (Half) 15 min

30 min

1 hr

2 hr

3 hr

6 hr

9 hr

12 hr

1month

2month

4month

6month

12month

24month

18month 0.9ml/day

0.7ml/day

8.3ml/day

4.2ml/day

2.8ml/day

1.4ml/day

Lube Cycle & Dispensing Equivalents

WARNING

Symptom Possible Cause of TroubleLCD Display Troubleshooting Steps

ㆍElectrical malfunction of CPU or circuitry

ㆍContact problem (open circuit) at buttons in

control panel

ㆍElectrical malfunction of CPU or circuitry

ㆍBattery pack installed incorrectly

ㆍFaulty or damaged battery pack

ㆍOld battery pack was not replaced

1. Make sure the battery pack is installed correctly

2. Replace battery pack

Contact your local supplier or manufacturer for either repair

or replacement

3. Contact your local supplier or manufacturer for either

repair or replacement

ㆍThe battery pack must be replaced when each dispensing

period set is complete

ㆍKeep battery pack stored in a cool, dry place to prevent

damage

ㆍExpired battery pack

ㆍExtreme storage conditions (temperature or

humidity)

ㆍFaulty or damaged battery pack

1. Ensure operating environment meets requirements

2. Replace battery pack

ㆍ

High backpressure in lube line due to ruptured

lube line, long distance remote installation etc.

Unit Won't

Operate

Low Battery

Indication

Excessive backpressure exists due to:

Unit Won't

Dispense Oil

Normal

Blank

Screen

ㆍLow battery power due to extreme operating

conditions

ㆍExtreme operating conditions

Use the included transparent dust cover

to keep the unit clean.

Output volume may vary depending on oil viscosity, length of lube line, ambient temperature, etc.

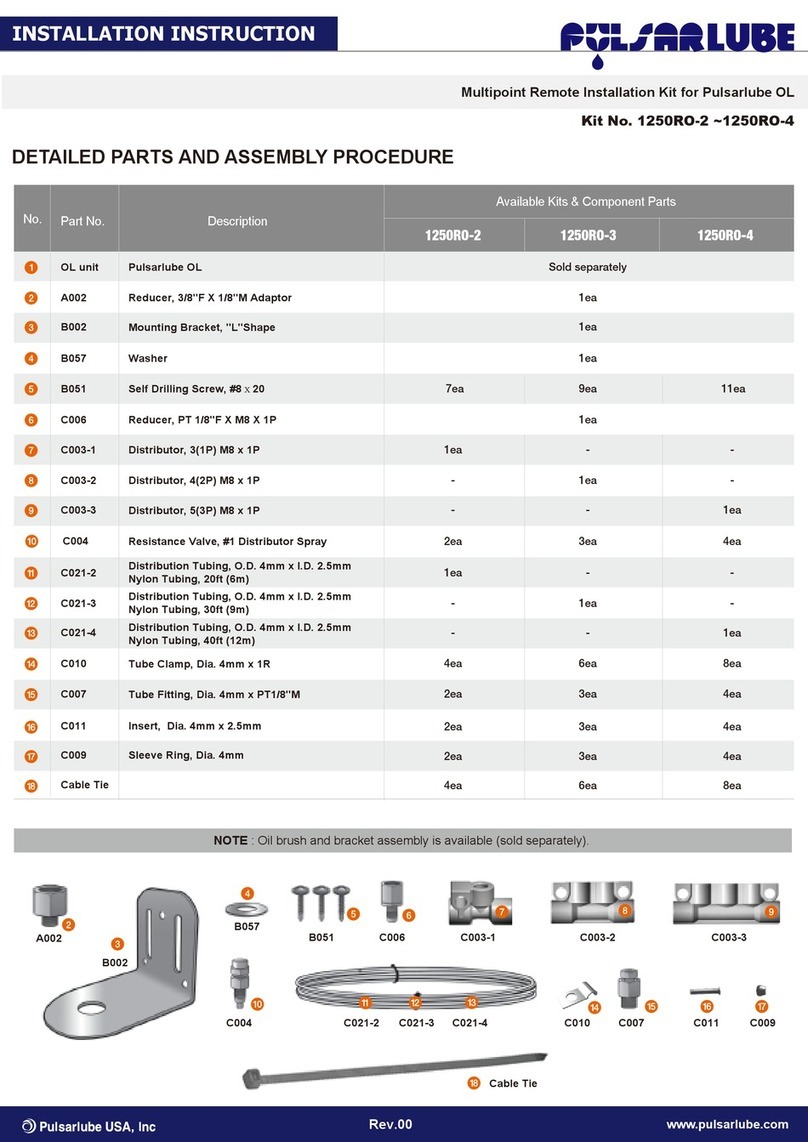

Assemble a single or multi-point remote

installation kit prior to installation of the

OL500.

Install the mounting bracket in a proper

location using screws provided.

Take the oil reservoir lid off and fill the

reservoir with oil to the 500ml level.

Turn the hand knob counter clockwise

1~2 turns before closing the lid to open

the vent and relieve vacuum pressure.

The Pulsarlube OL500 is a reusable unit but the battery pack must be replaced when each dispensing period set is complete.

1

2 3

4 5 6

CAUTION

CAUTION

The installation date and the scheduled

date of lube cycle completion should be

logged for maintenance purposes.

Mount the Pulsarlube OL500 unit in

close proximity to the lube point to keep

the total length of feed lines as short as

possible.

Use of standard Pulsarlube oil distributor is

recommended to ensure proper lubrication.

If after running test mode is

still present:

ㆍ

Replace battery pack

ㆍ

Check backpressure in lube line

ㆍ

Check grease dispensing rate

ㆍ

Reduce remote installation distance

ㆍ

Use a lithium battery pack in

extreme environments

If after running test mode is

no longer present, it is okay to

reinstall the lubricator.

unlock

ㆍResolve the cause of backpressure

before reinstalling lubricator

Turn on the lubricator and press the TEST

button for 2 seconds to run a test cycle.

The unit will start to dispense oil and operate

continuously in purge / test mode.

This process will last approximately 2 minutes

to ensure every function of lubricator works

properly.