Operation

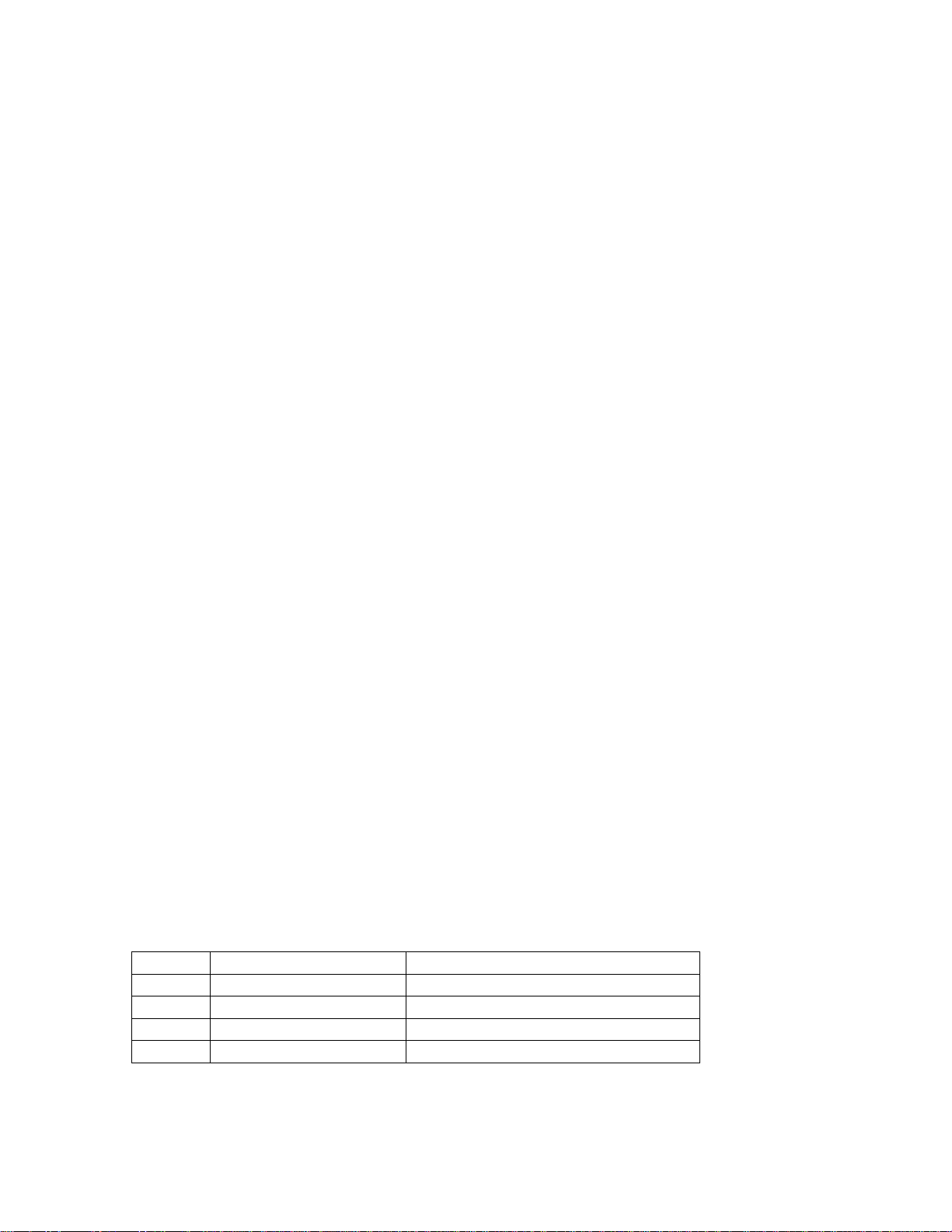

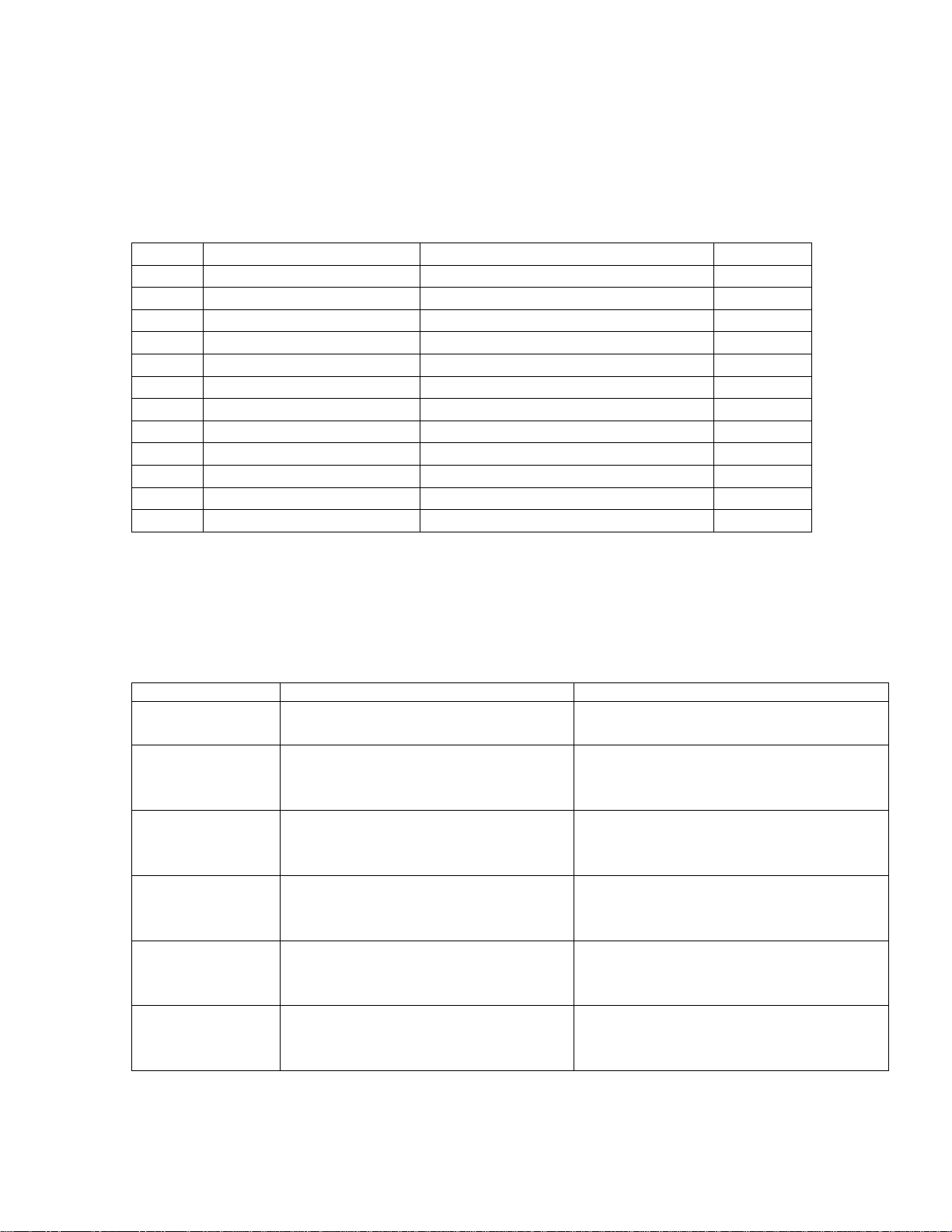

Refer to assembly drawing 112-2928 for part reference numbers.

1) Plumb up the valve as outlined above in the Setup procedures.

2) Being sure the valve is not aimed toward anyone, pressurize the fluid delivery

system. Note: The fluid pressure must be set to a minimum of 15psi. to flex the

diaphragm to the open position.

3) Cycle the valve to the open position by depressing the lever (7) to purge. Fluid

should begin to dispense from the tip of the valve. Continue dispensing until all

air is removed.

4) Check fluid connection for leaks. If the valve is leaking or dripping, refer to the

Troubleshooting section.

5) Adjust the material pressure until the desired flow rate is achieved.

6) Fine tune the flow rate with the stroke adjustment nut (5). First loosen the set

screw (11) with a .050” Allen key then turn the stroke adjustment clockwise to

increase flow and counter-clockwise to decrease the flow rate. If the stroke is

loosened too far out then the valve will not open.

7) Once the stroke adjustment setting is determined, retighten the set screw (11)

using a .050” Allen key.

Note: Refer to Troubleshooting section for any problems.

Routine Cleaning and Disassembly

Cleaning and rebuilding the valve will be required from time to time. A spare

parts kit, part # CAM2-SP is available with all the normal wear parts included.

1) If possible, flush the valve thoroughly with an appropriate solvent before

disassembly. (Refer to MSDS sheets of fluid for suggested solvent)

2) Begin disassembly by first removing fluid pressure from the system.

3) Remove all fluid delivery fittings, hoses, etc. from the valve.

4) Using the tip of a 9/64” Allen key, remove the four machine screws (12) that hold

the top cap (1) to the fluid section (3).

5) Lift off the top cap assembly and remove diaphragm (2).

6) Using an adjustable wrench, unthread and remove the plastic luer adapter (9) from

the fluid section (3).

7) Clean all of the wetted parts thoroughly with an appropriate solvent.

8) Using a .050” Allen key unthread and remove the set screw (11) that threads into

the stroke adjustment nut (3).

9) Unthread and remove the stroke adjustment nut (3) from the piston (4) which will

allow the piston and spring (8) to slide out through the bottom of the top cap (1).

10)Using a .050” Allen key unthread and remove the two set screws (11) that thread

into the standoffs (6).

11)Slide the dowel pin (10) out of the standoffs (6) and lever (7) to separate them

from the top cap (1).

•Replace components with spares provided in the spare parts kit.