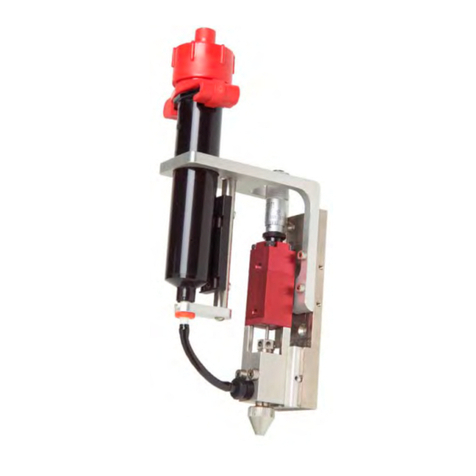

SV200

Servo Driven Auger Style Dispense Valve

Thank you for purchasing the SV200 dispensing valve from PVA. Before

attempting to operate the SV200, we recommend that you take a few minutes and read

the following operation and setup manual. This will assist in familiarizing you with the

product and ensure a successful installation.

As always, if any questions or problems arise, do not hesitate to contact PVA’s

Valve Service Department for support. This department can be reached at PVA

headquarters via telephone or e-mail.

Again, thank you for your purchase, and we look forward to assisting you in the

future as you continue to improve your dispensing processes.

Theory of Operation

The SV200 uses a servo driven motor to rotate an auger inside the luer adapter of

the valve to provide a form of positive displacement control over fluid flow. Typical

applications include applying consistent bead patterns and dots of fluid where a high

degree of accuracy is required. With the quick release function of this valve, the motor

and auger assembly can be quickly removed from the luer adapter to clean the wetted

section. This valve is typically supplied with an SVC100 controller which is used to

program auger speed, dispense time, reverse time, and air pressure.

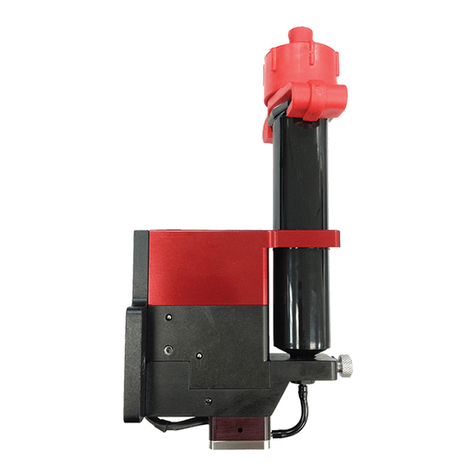

The SV200 has a divorced design comprising of two major sections. These include:

1) Servo Motor Drive (upper section)

2) Fluid Section (Red anodized aluminum and stainless steel)

The upper section is a servo drive motor used to accurately control the speed of

the auger screw and time that it rotates in the forward and reverse direction. The SCV100

controller has a digital display to select and program all parameters that will determine

fluid flow rate, shot size, and suck back.

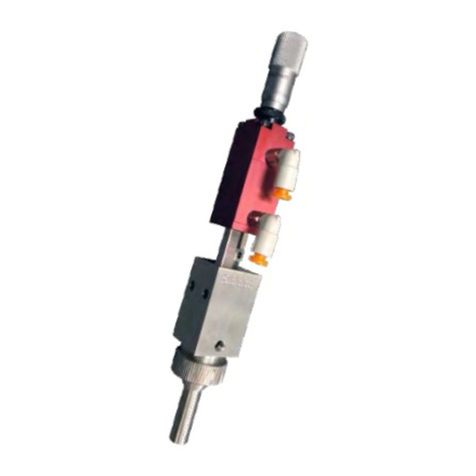

The fluid section uses an aluminum retainer to house a stainless steel luer adapter

which acts as the fluid chamber. A screw type auger fits tightly inside to feed fluid

through to the dispense tip. The auger is connected directly to the servo motor and the rate

at which it is turned inside the luer adapter will determine fluid flow rate and dispense

volume. With little wear between the luer adapter and auger, this valve was originally

designed to dispense filled and abrasive pastes and fluids.

Wetted parts on the SV200 include:

- 304 stainless steel

- Aluminum, Red Anodized

- Viton, standard