Table of Contents1.

Table of Contents ..................................................................................... 31.

Introduction ............................................................................................. 52.

Document History ............................................................................................... 52.2

Safety .................................................................................................................. 62.3

Theory of Operation............................................................................................72.4

Personal Protective Equipment ..........................................................................72.5

Waste Disposal.................................................................................................... 72.6

Necessary Tools ..................................................................................................72.7

Setup........................................................................................................ 83.

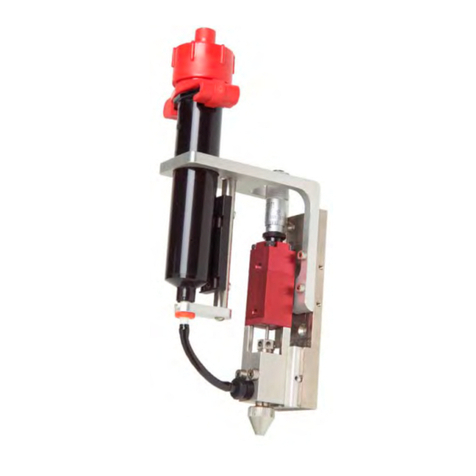

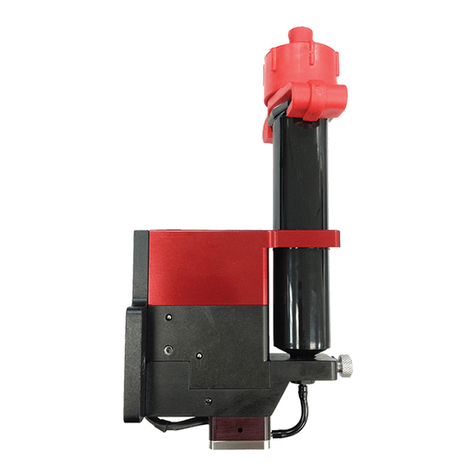

Overview .............................................................................................................83.1

Operation................................................................................................. 94.

Bleed the Valve ...................................................................................................94.1

Shutdown..........................................................................................................104.3

Maintenance .......................................................................................... 115.

Valve Lubricant ................................................................................................. 115.1

Disassembly.......................................................................................................115.2

Clean the Valve Components............................................................................225.3

End Cap ..................................................................................................... 225.3.1

Fluid Body..................................................................................................235.3.2

Separation Body........................................................................................ 235.3.3

Air Cylinder................................................................................................235.3.4

Air Cap....................................................................................................... 245.3.5

Assemble the Valve........................................................................................... 245.4

To Replace O-rings ............................................................................................395.5

To Replace Lip Seals ..........................................................................................405.6

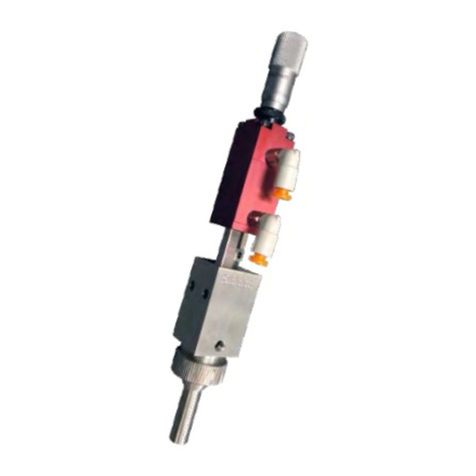

Exploded View........................................................................................ 416.

Exploded View of the NPT Version ...................................................................416.1

Item Numbers and Descriptions for 112-07519, NPT version .......................... 426.2

REVISION A (2014) 3 of 50