PB 1

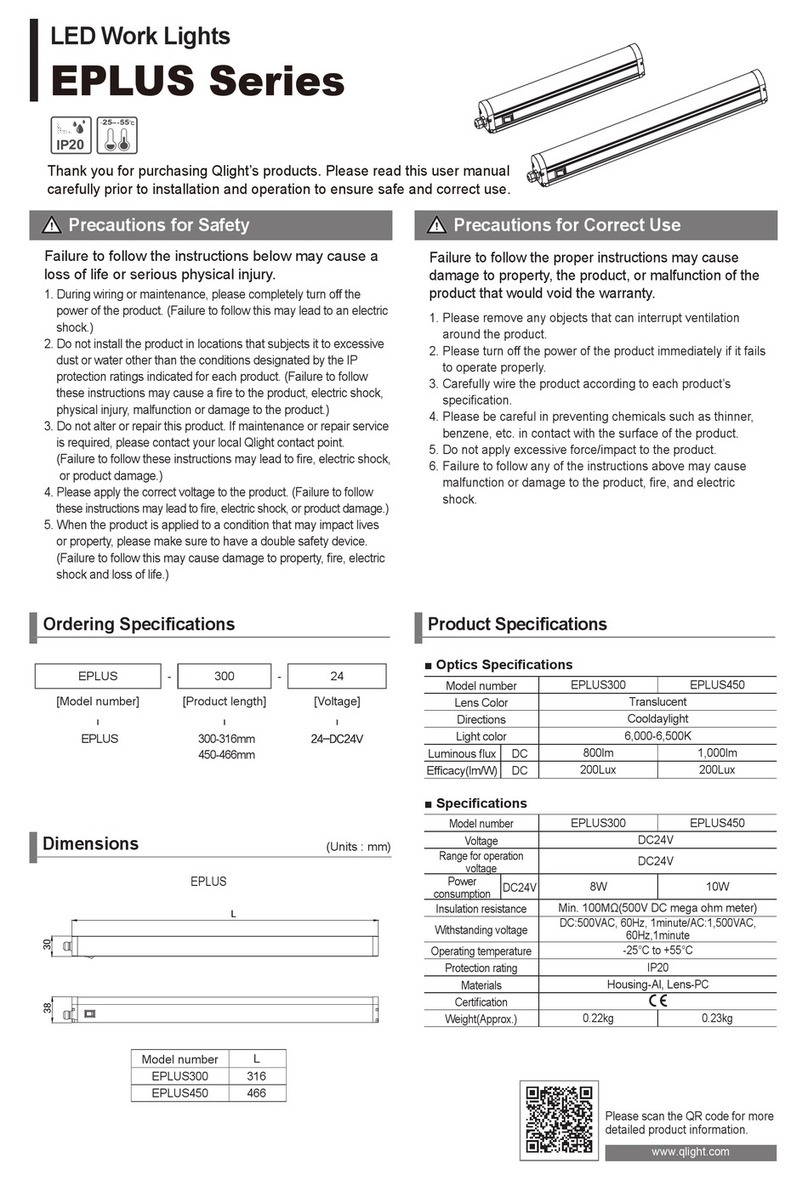

Explosion Proof LED Work Light

QLEX-SLM series

Thank you for purchasing Qlight’s products. Please read this user manual carefully

prior to installation and operation to ensure safe and correct use.

1. During wiring or maintenance, please completely turn o-• the power of the product. (Failure to follow this may lead to an electric shock.)

2. Do not install the product in locations that subjects it to excessive dust or water other than the conditions designated by the IP protection

ratings indicated for each product. (Failure to follow these instructions may cause a ¿re to the product, electric shock, physical injury,

malfunction or damage to the product.)

3. Do not alter or repair this product. If maintenance or repair service is required, please contact your local Qlight contact point.

(Failure to follow these instructions may lead to ¿re, electric shock, or product damage.)

4. Please apply the correct voltage to the product. (Failure to follow these instructions may lead to ¿re, electric shock, or product damage.)

5.

When the product is applied to a condition that may impact lives or property, please make sure to have a double safety device.

(Failure to follow this may cause damage to property, ¿re, electric shock and loss of life.)

Precaution for Safety

Failure to follow the instructions below may cause a loss of life or serious physical injury.

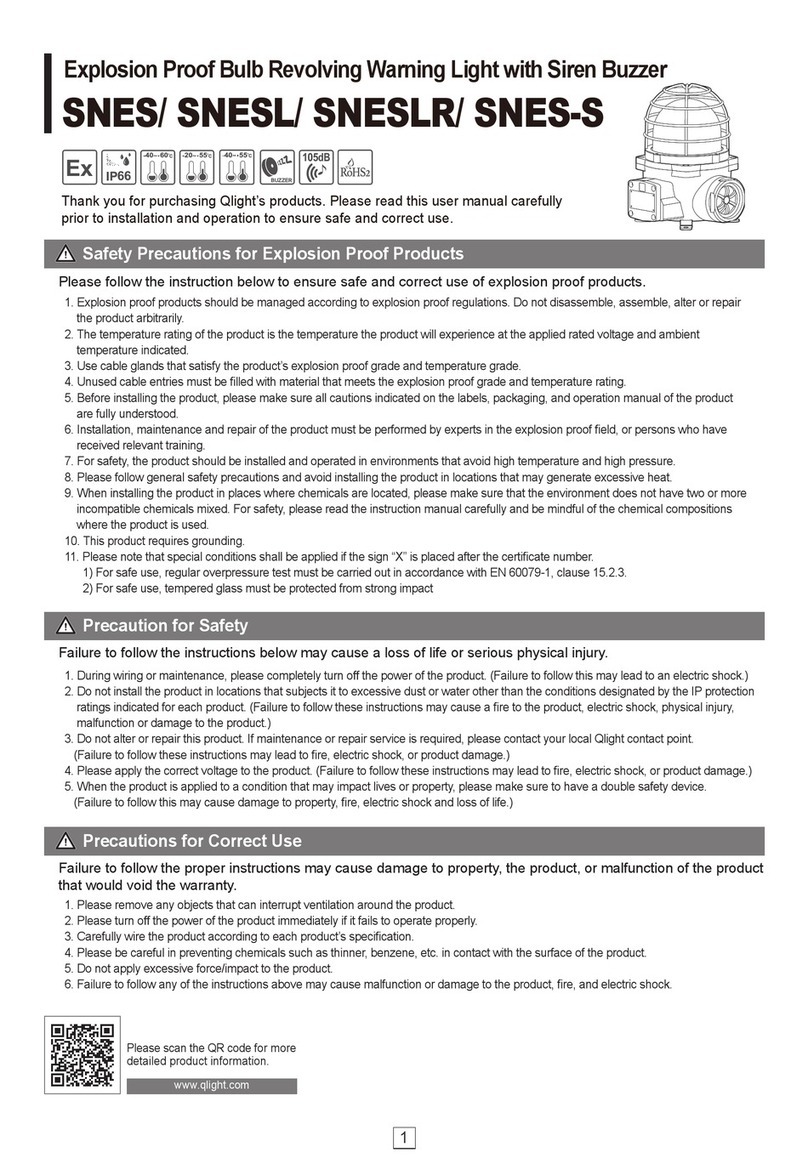

Safety Precautions for Explosion Proof Products

Please follow the instruction below to ensure safe and correct use of explosion proof products.

1. Explosion proof products should be managed according to explosion-proof regulations. Do not disassemble, assemble, alter or repair

the product arbitrarily.

2.

The temperature rating of the product is the temperature the product will experience at the applied rated voltage and ambient

temperature indicated.

3. Use cable glands that satisfy the product’s explosion proof grade and temperature grade.

4. Unused cable entries must be ¿lled with material that meets the explosion proof grade and temperature rating.

5. Before installing the product, please make sure all cautions indicated on the labels, packaging, and operation manual of the product are

fully understood.

6. Installation, maintenance and repair of the product must be performed by experts in the explosion proof ¿eld, or persons who have

received relevant training.

7. For safety, the product should be installed and operated in environments that avoid high temperature and high pressure.

8. Please follow general safety precautions and avoid installing the product in locations that may generate excessive heat.

9. When installing the product in places where chemicals are located, please make sure that the environment does not have two or more

incompatible chemicals mixed. For safety, please read the instruction manual carefully and be mindful of the chemical compositions

where the product is used.

10. Static electricity may be generated by physical contact due to the surface characteristics of this product so please use a wet towel

or anti-static cleaner to remove the foreign substances on the product.

11. Please be careful of static electricity during product installation.

Please eliminate static electricity by using static eliminator or handle the product with anti-static globes.

12. Be cautious of generating static electricity when installing the product. To avoid static electricity , use static-protective accessories or

Where anti-static gloves when handling the product.

13. Please note that special conditions shall be applied if the sign “X” is placed after the certi¿cate number.

14. For safe use, regular overpressure test must be carried out in accordance with EN 60079-1, clause 15.2.3.

15. For safe use, tempered glass must be protected from strong impact

1. Please remove any objects that can interrupt ventilation around the product.

2. Please turn o-• the power of the product immediately if it fails to operate properly.

3. Carefully wire the product according to each product’s speci¿cation.

4. Please be careful in preventing chemicals such as thinner, benzene, etc. in contact with the surface of the product.

5. Do not apply excessive force/impact to the product.

6. Failure to follow any of the instructions above may cause malfunction or damage to the product, ¿re, and electric shock.

Precautions for Correct Use

Failure to follow the proper instructions may cause damage to property, the product, or malfunction of the product

that would void the warranty.

Please scan the QR code

for more

detailed product information.

www.qlight.com

6040

Ex