Bed Height. . . . . . . . . . . . . . . . . . . . ............6

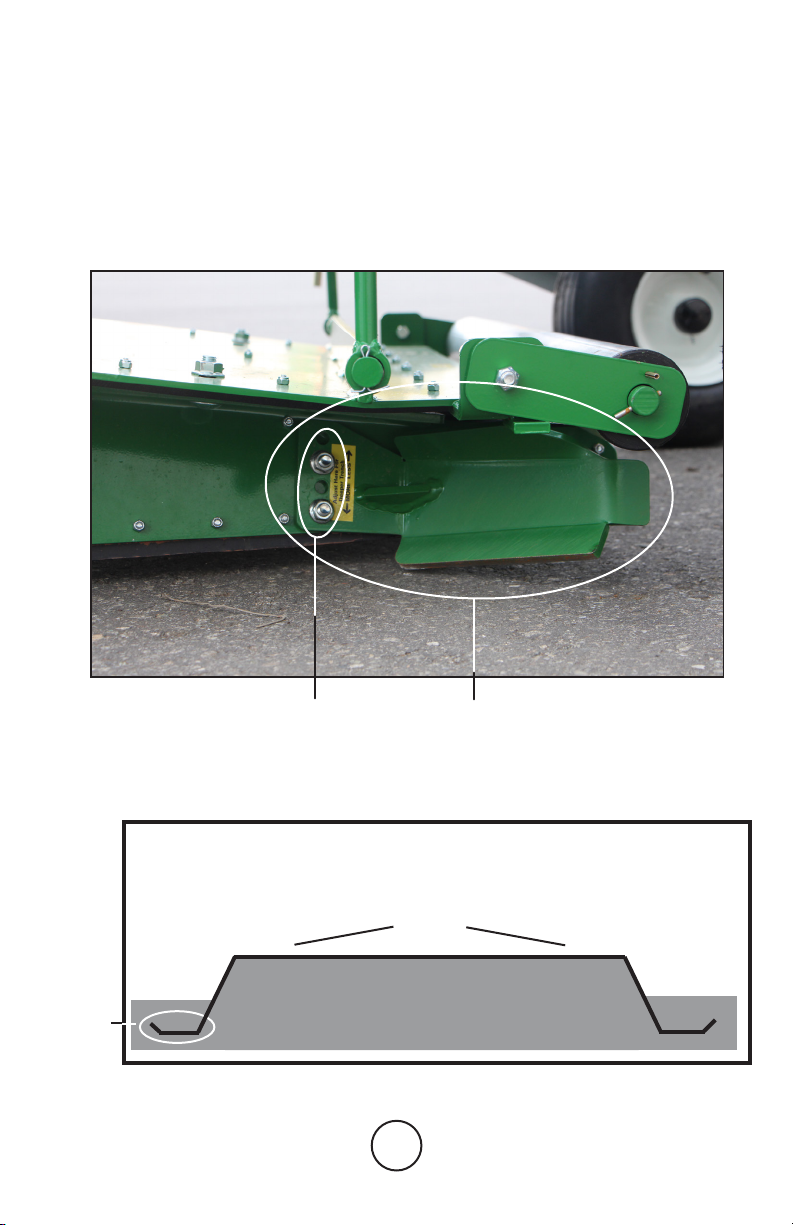

Bed Press................................7

Bed Width . . . . . . . . . . . . . . . . . . . . ............7

Chisel Tooth. . . . . . . . . . . . . . . . . . . ..........12

Cover Disk . . . . . . . . . . . . . . . . . . . . ..........11

Dirt Shield...............................11

Drip Irrigation Attachment . . . . . . . . . . . . . . . . . . 15

Drip Tape Down Pipe ......................15

Getting Started .. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Features .................................4

Helpful Tips..............................30

Options ..................................4

Parts Breakdown, Descriptions ...........24-28

Parts Breakdown, Exploded Views.........17-23

Plastic Rolls, Installing ......................8

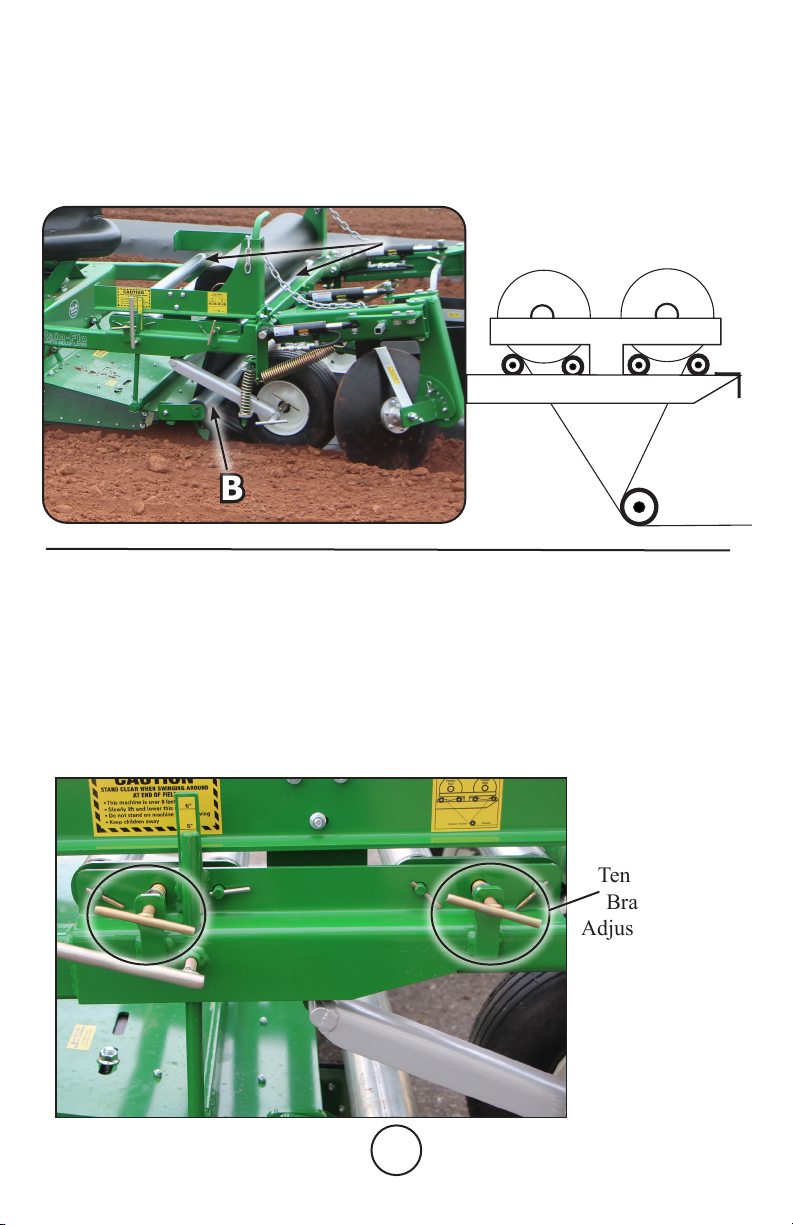

Plastic Tensioning . . . . . . . . . . . . . . . . . . . . . . . . . 8

Plastic Width. . . . . . . . . . . . . . . . . . . . .........16

Preparation Of Soil . . . . . . . . . . . . . . . . . . . . . . . . 4

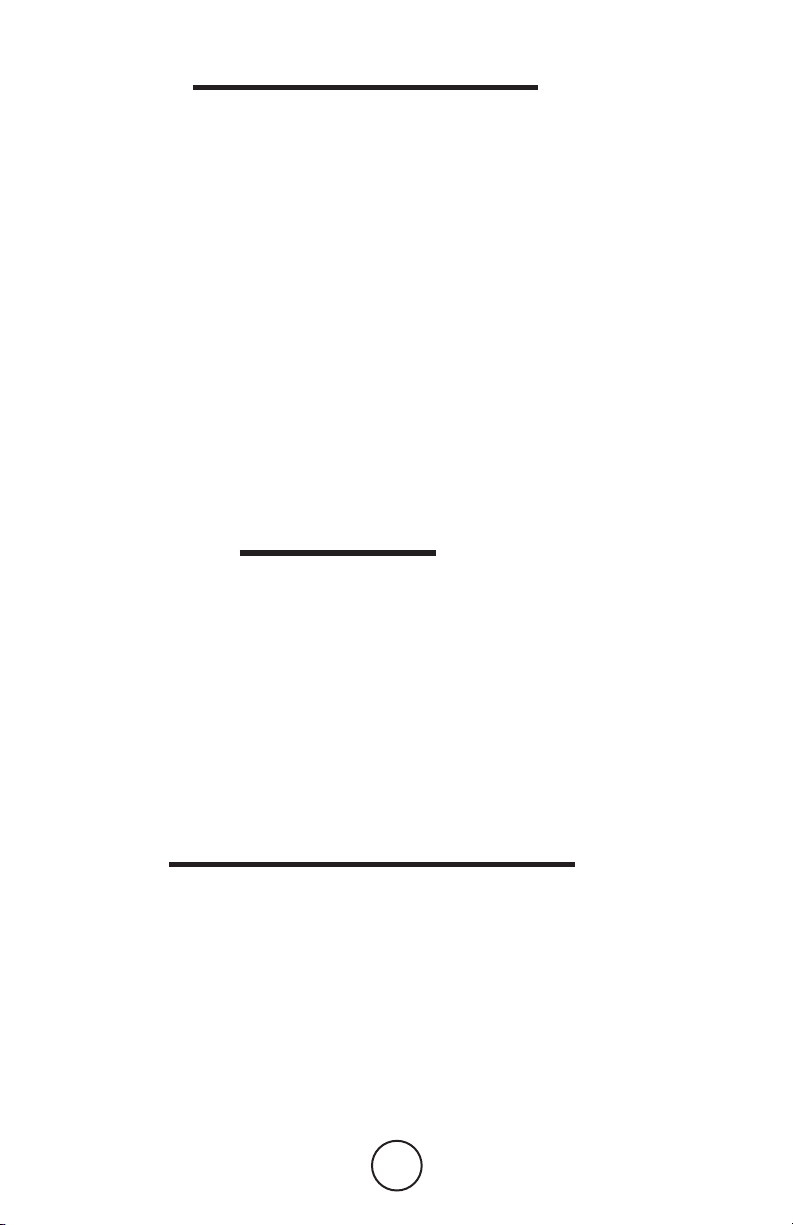

Press Wheel . . . . . . . . . . . . . . . . . . ...........9

Ro-Trak, Maintenance. . . . . . . . . . . . . . . . . . . . . 14

Ro-Trak, Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ro-Trak, Trouble Shooting ..................14

Safety First ...............................3

Trench Opener . . . . . . . . . . . . . . . . ..........10

Trouble Shooting. . . . . . . . . . . . . . . . . . . . . . . . . 31

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2

Table Of Contents