GB

DONOTOVERLOOK!

Maintenance and cleaning should only be carried out on painted and glass parts with soft non-abrasive cloths and cleaning liquids. Do not use any abrasive pastes,

wirewoolorchemicalcleanerse.g.,thinners,acetoneetc.Themanufacturerisnotliablefordamagecausedbywrongorcarelessuseofcleaningmaterials.

The manufacturer recommends the use of the following Ravak products: RAVAKANTICALC CONDITIONER - To be used for perfect maintenance of the protective

Anticalc glass layer. This layer is factory applied to all safety glass panels. Easy application-perfect results. RAVAK DISINFECTANT - A solution with significant

disinfecting effects-intended for versatile use in every household, also recommended for maintenance of bathtub hydromassage systems. RAVAK CLEANER - This

highefficiencydetergenthasapleasantfragrance.TheproductcomplementstheseriesofspecializedchemicalsbyRAVAK.

Provided that installation is carried out in a professional manner and in accordance with above schedule, the product is subject to 24 months warranty. In alternative

cases,localcountryorEUlawswillprevail.Themanufacturerisnotliablefordamagecausedbyincorrectinstallation,useormaintenance.

Forfurtherinformation,contactyourlocalRavakdealer.

Themanufacturerreservestherighttoamendorimproveonexistingdesignsorfeatures.

Please help preserve the environment by observing local country guidelines or laws regarding re-cycling. Materials which are not suitable for re-cycling must be

disposedofatanofficialandsuitablewastecontrolcentre.

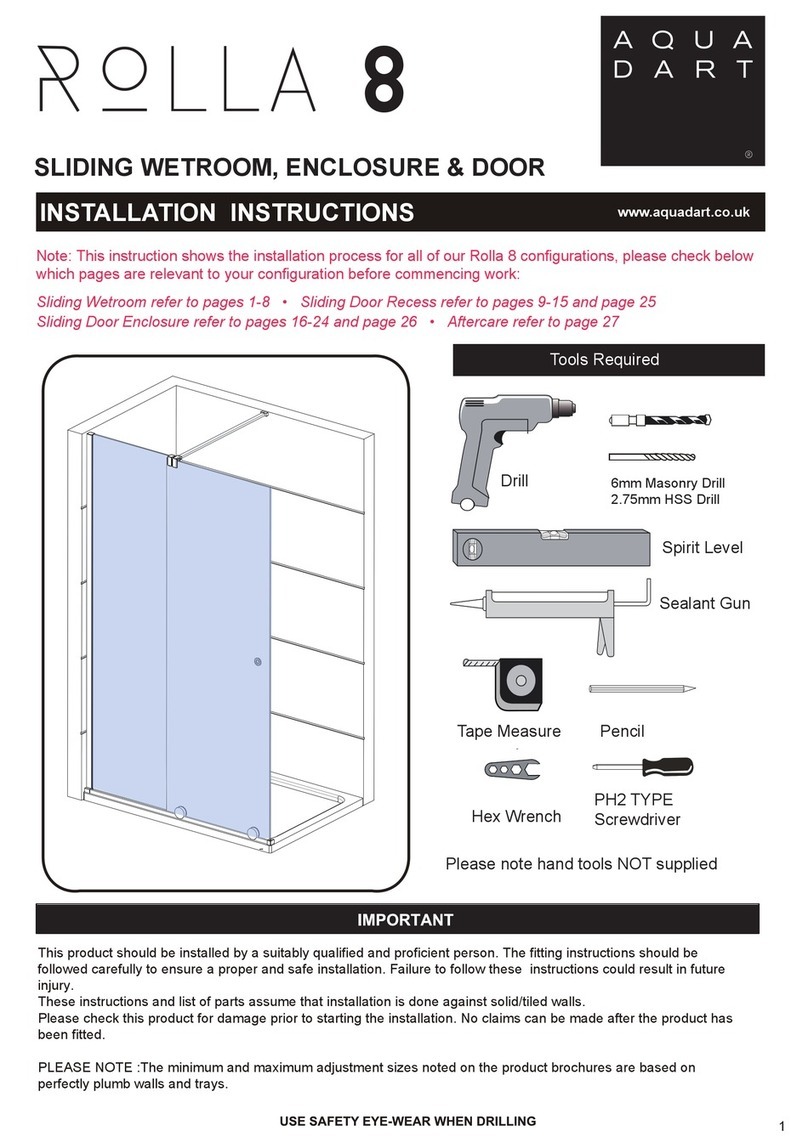

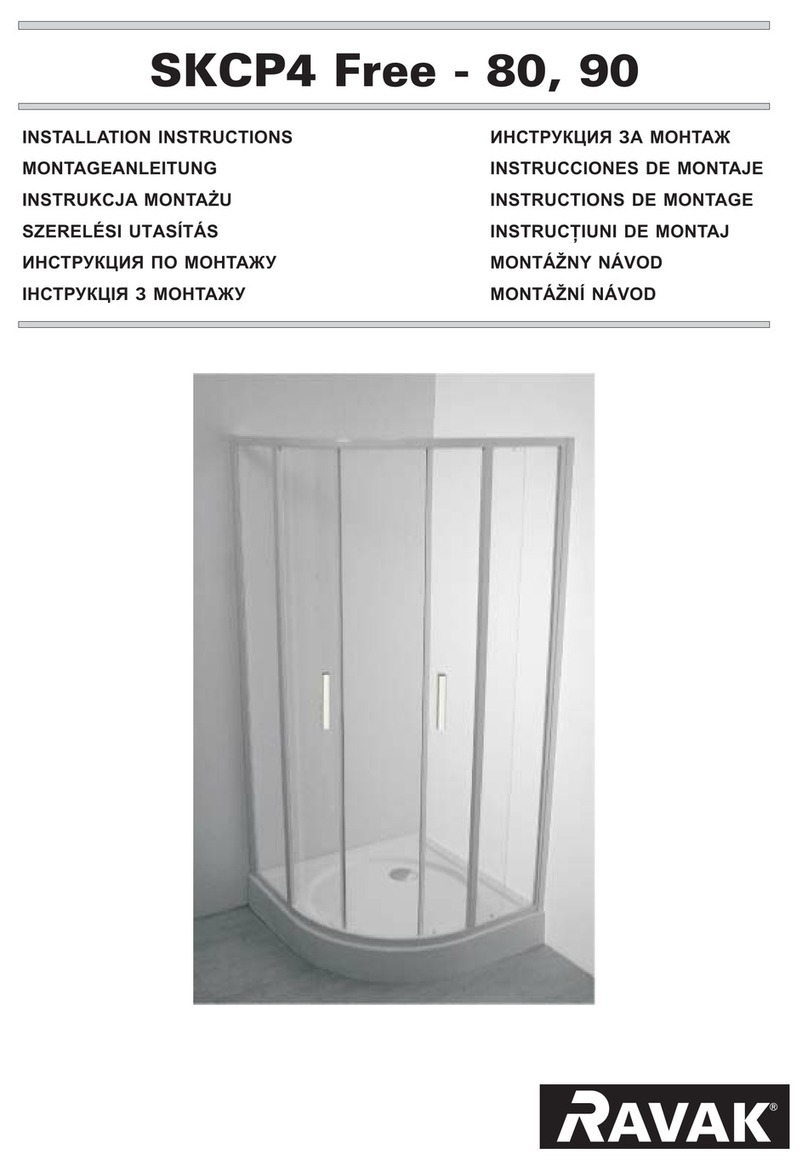

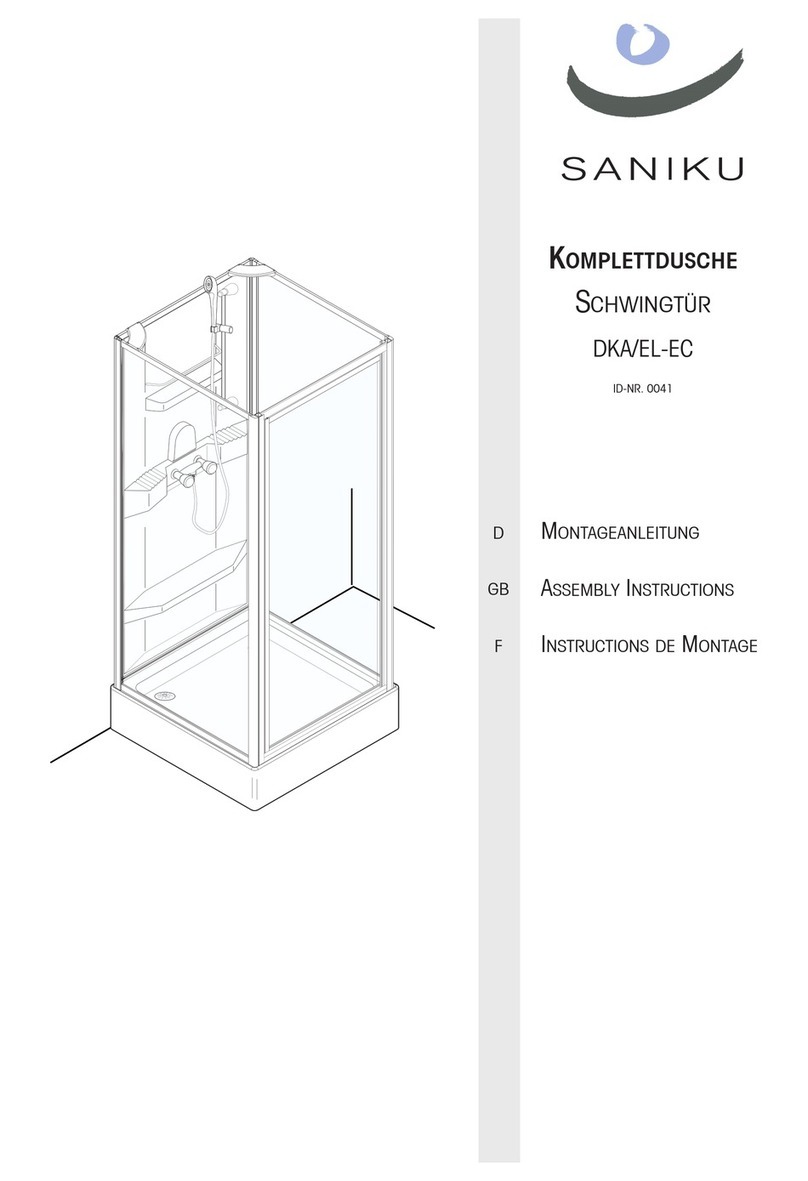

ASSEMBLY INSTRUCTIONS

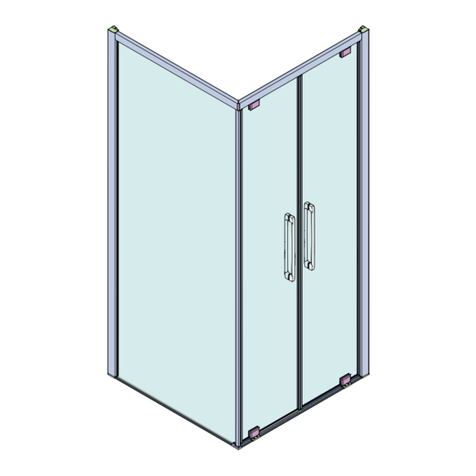

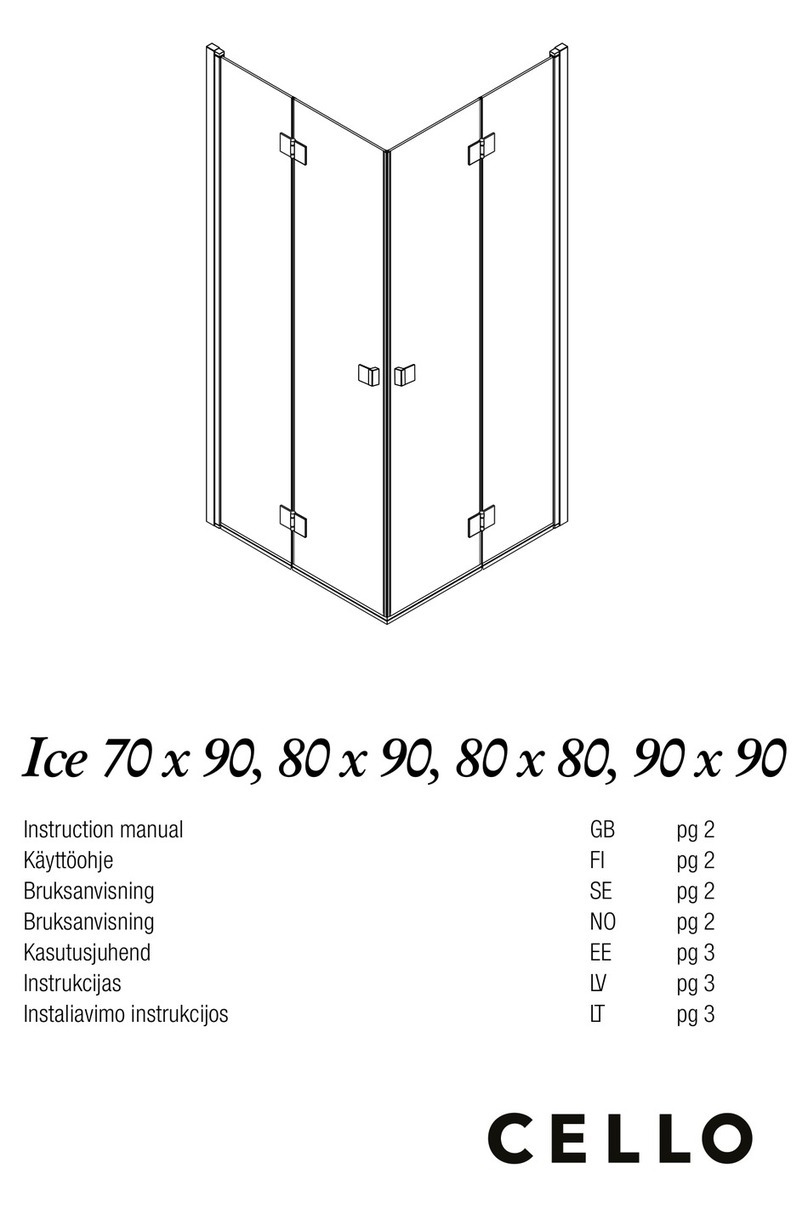

FOUR-PART CORNER ENTRY SHOWER DOOR PAIR GSRV4

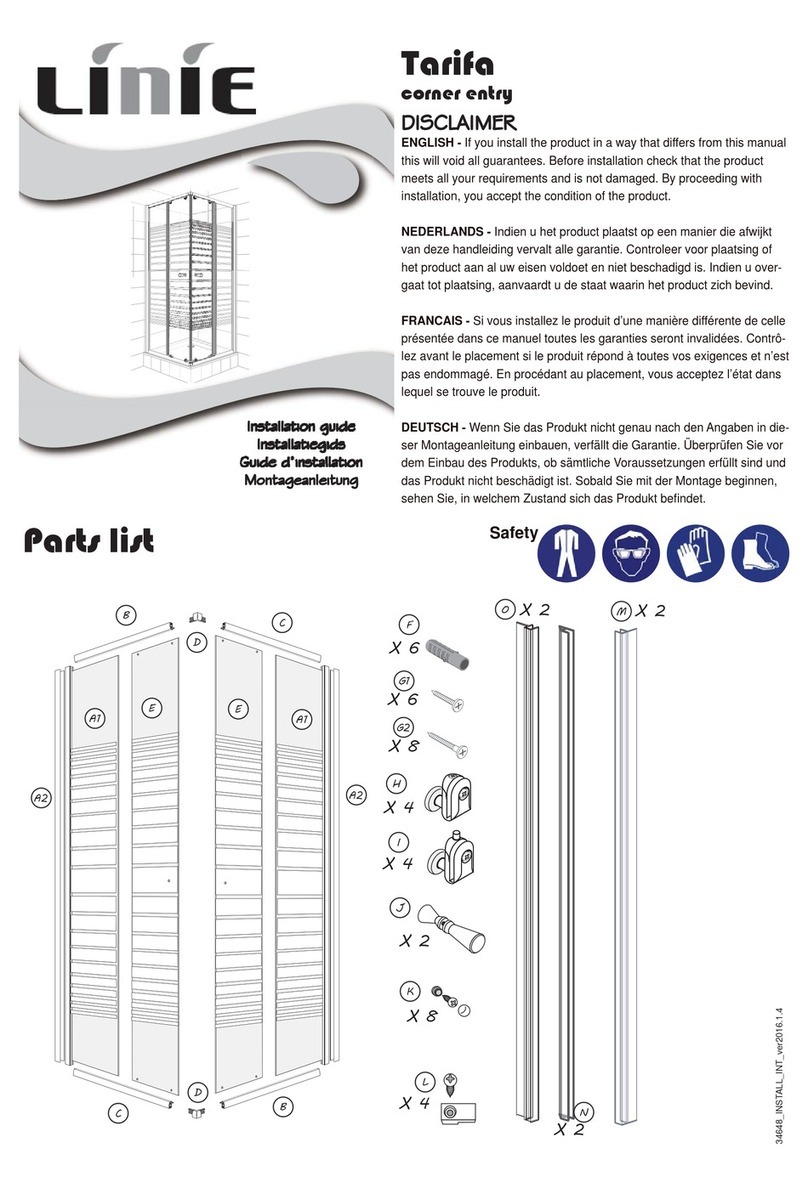

The product is for mounting in a totally finished (tiled, plumbed, etc.) bathroom and fitted shower tray (if used). The constructional dimensions and/or shower tray

dimensions must be in strict accordance with the dimensions of the selected shower door or enclosure i.e. nominal 80, 90, 100, 110, or 120 cm. according to type.

For best results, the product must only be fitted to a strong and rigid, solid bathroom wall that is vertical and adjacent walls should be square to each other.

WARNING:when manipulatingthe glass panels,always ensure that some soft material is placed under the bottom edge,for protection.

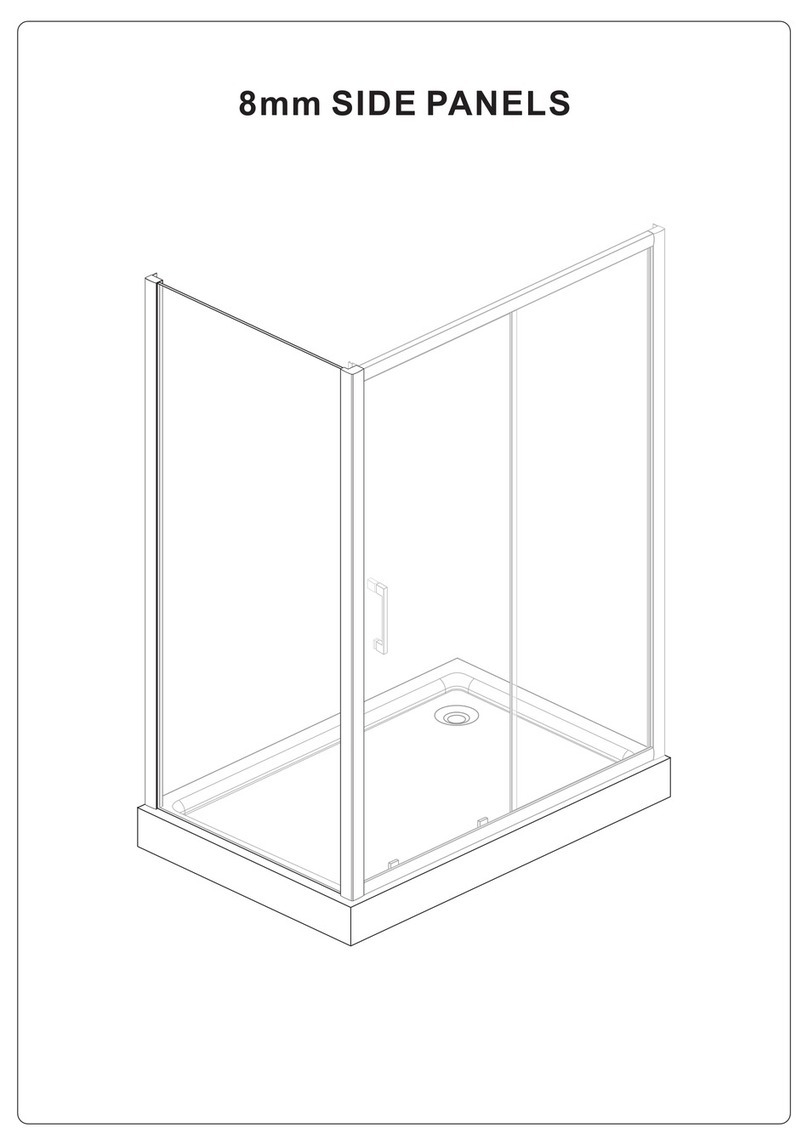

Un-pack and prepare individual glass components according to the scheme for left (and right) variants. The glass for the fixed wall with a thickness of 8mmat

the wall has two fixing holes and on the other side there are 4 holes for door hinges. The door glass has 2 holes for hinges and on the other side there is 1 hole for

thehandle halfway up the height of the door.Marksontheglassmustbereadable when viewed from the outside.

Fit the long plastic sealing profiles to the vertical edge of the fixed glass walls on the sides where they will contact the wall. For easier manipulation, dampen the

sealswith a little soapy water.(Item1)

Ontothe opposite edge of the fixed glass walls, fit the long softedged door seals. (Item 2)

Fit to the fixed glass walls, the dismantled halves of the hinges, the lower part of the hinges, with the side for the screw on the inner side of the glass. Repeat with

theupper hinge parts onto the folding doors. Ensure that protection pieces arein place. Never fit hinges directly metal to glass without the protectionpieces.

On to the wall edge of the fixed glass walls, mount the wall brackets, angled side on the inner side, flat side on the outer side and lightly tighten. The final

tighteningforce after all adjustments are made should be 4-5Nmtorque.

According to the diagram 6-7-8,measure and mark points for drilling from the top of the shower tray (or tiling) up for the centre of the bracket holes. The front

face of the fixed glass wall should sit 19 mm from the outer edge of the shower tray and the centres of the mounting brackets should be 745/845/945 mm from the

face of the back wall depending on the nominal size of the shower tray, 800/900/1000 mm. Insert the temporary white moulded plastic parts under the glass wall

so that it will have a 2-3 mm space underneath for later filling. Ensure correct measurements are maintained and that measurement points are vertical by a spirit

level.

Drill 2 holes 8 mm dia. to depth of 60 mm. Fit the special 'Mungo' plastic wall plugs. Onto the adjacent wall, again mark for two holes as before, in accordance

with the diagram, 745/845/945 mm from the face of the side wall as before. Drill two holes 8 mm dia. to a depth of 60 mm and insert the other two 'Mungo' wall

plugs.Fit the other two wall brackets and again set the second fixedglass wall with the white moulded plastic parts underneath.

Washers and screws are included for fitting components to traditional walls of brick and plaster or cement. If other wall materials are used, other full strength

fittingcomponents must be utilised in accordance with manufacturers advice.

Setfixed glass walls vertical, fit and tighten the two sets of 5x 60 mm screws. For setting level to the base, adjust thewhite moulded plastic parts, as necessary.

Fit the magnetic seal profiles to the doors with the angle faces pointing inward. Fit the doors onto the hinges. Fit the door handles with the correct plastic

sleevesin the hole of the door and plastic washers between the handlesand the glass. Never fit metal directly to glass.

Adjust the doors so that they are level. Check the contact of the magnet seals against each other ensuring they meet together correctly for the whole vertical

length.

The gap between the door glass and the fixed glass walls must be even and approximately 4 mm when the door is in the closed position. The soft seals will fill

thisspace.

If necessary, loosen the screws in the brackets of the fixed glass walls. The doors can then be moved by ± 6 mm. Never adjust the plastic with magnetic strip

profiles,which are attached to the doors.

When the product is correctly adjusted, it should have the top edges of the glass panels level with each other and horizontal. The edges of the doors and fixed

wall panels must be level with the shower tray edge and the magnetic strips must make proper contact over the whole length of the strip. In the case of uneven

walls or tiling, it is possible to make compensation by using the flexible mounting washer part underneath the relevant wall brackets. (Diagram 14). The brackets

must be in one vertical line and the gap between the upper and lower part of the hinge must be the same for both hinges. The final gap under the fixed walls should

stillbe 2-3mmandundertheglassdoorsshouldbe32-33mm.

DOUBLECHECKtightness of all connections.Tighteningtorqueofglassagainstbrackets or hinges should be 4-5Nm.

Ensurethe sealing profiles between the fixed glass walls and tiled walls arepushed hard in.

Onto the lower edge of the doors, use silicon putty to fitthe small draining seal.

Usesilicon putty to fit the threshold strip parallel with the door.Thecorrectpositionis9mmfromthe outer edge of the glass. (See picture 17).

Using the Ravak transparent silicon putty, fill all seals from the external side of the vertical connections between the fixed glass wall and the tiling. Discard the

temporary plastic pieces and fill the horizontal gap underneath the fixed glass wall. Fill along the edges of the threshold strip. Fill along the edges of the small

draining seal. Place a knob of silicon on top of the bracket screws and press into place the stainless steel bracket covers with the flat face outermost. When set,

removethe protective foil.

Where this component is part of the product contents, attach the strut to the upper edge of the fixed glass wall(s). Find the position where the opposite end

touches the wall and make a mark for the centre of the wall bracket. Drill a hole 8 diameter x 60 deep. Fit a wall plug and screw bracket to wall with a 5 x 60 screw.

Fastenthe opposite end to the glass with bolt M8 x 8 mm.Repeat as necessary.

1.

2.

3.

4.

5.

6.

7.

Warning:Becarefultoavoidelectric,waterandgaspipeshidden beneath plasterwork or tiling.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.Alternativemountingstrut:

ASSEMBLYSEQUENCE: