CONTENTS

A Word or Two About Service ………

Introduction …………..........................

Service Data Chart................................

PART I—SERVICE DATA

PART II—MAKING REPLACEMENTS

ILLUSTRATIONS

Page

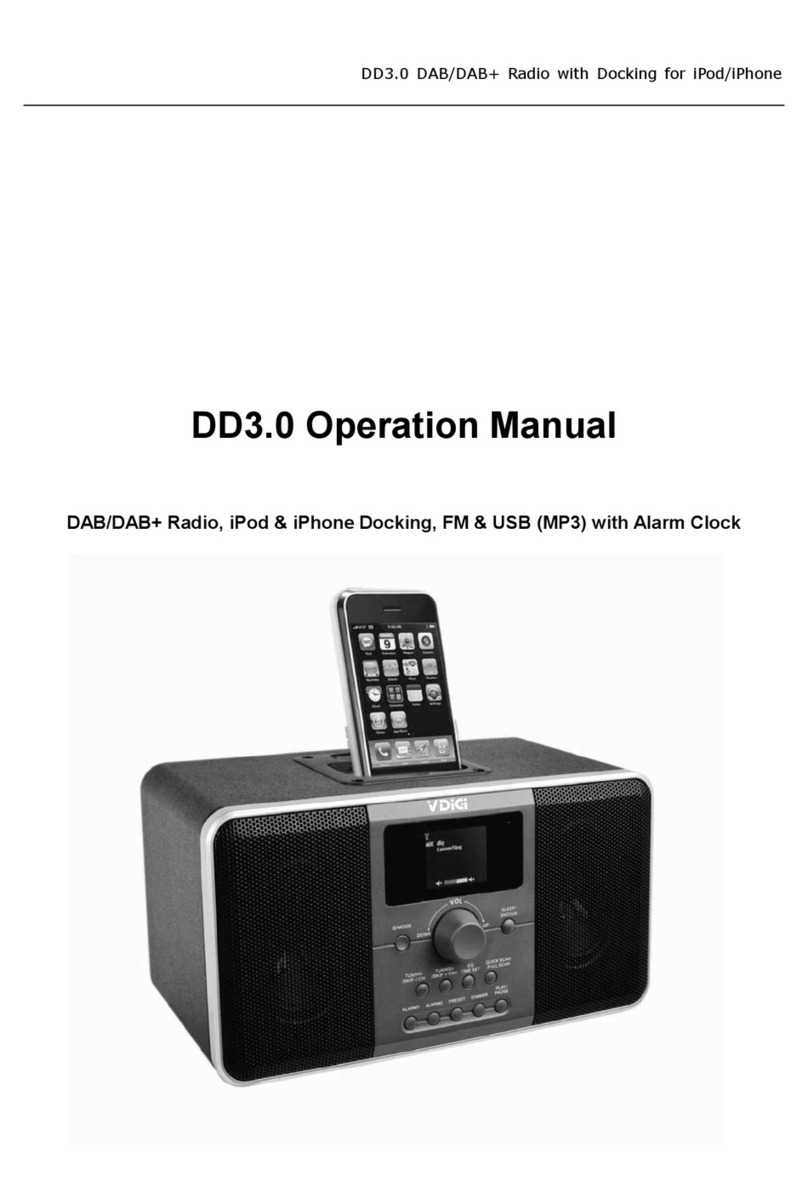

RCA Radiola 17 ...............„.............................:........ 1

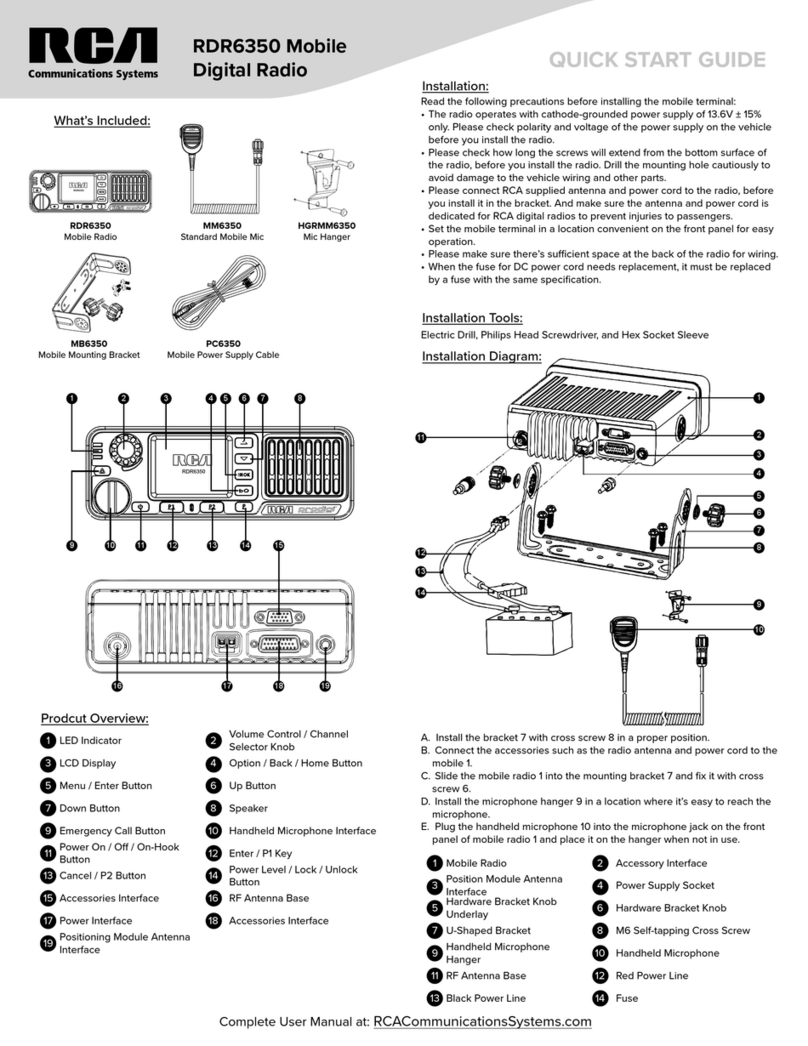

Top View of Chassis Assembly................................. 4

Socket Power Unit Showing Parts.................................. 5

Radiotron Sequence ................................................... 5

Schematic Circuit Diagram of Receiver………………. 6

Schematic Circuit Diagram of S.P.U.............................. 7

Radiotron Socket Contacts ........................................ 8

Method of Cleaning Radiotron Prongs.......................... 9

Releasing Volume Control ......................................... 10

Adjusting Contact Arm of Volume Control ................ 11

Turning Cable Adjusting Screw...... …………… .. 12

Condenser Cable and Drum Mechanism……………. 13

Schematic Circuit for Resistance Measurement.......... 14

Adjusting Potentiometer tor Minimum Hum ............. 16

Page

View of Pilot Light Socket and Canopy. …….….... 17

Wiring Diagram of Sub-Chassis Assembly ……....... 18

Continuity Wiring Diagram of S.P.U.......................... 19

Internal Connections of Filter Condensers ............... 20

Schematic Circuit for Securing Grid Voltages.......... 21

Removing Receiver Assembly from Cabinet…… ….22

emoving Receiver Assembly from Cab-22

Page

Radiotron Sequence .................................................... 6

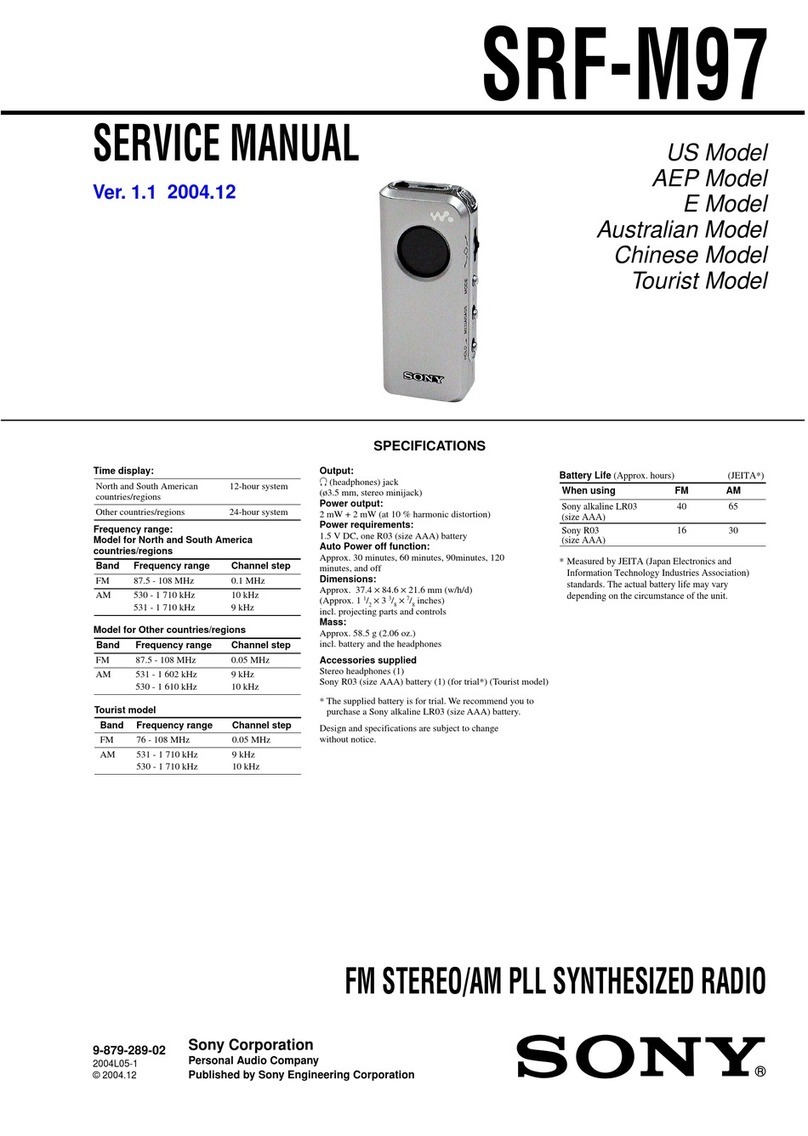

Circuit Characteristics ................................................ 6

Radiotrons.....;..................................................... 7

Antenna Installation (Outdoor)........................ 8

Antenna Installation (Indoor)........................... 9

Ground ........................................;.............................. 9

Antenna System Failures ....................................... 10

Radiotron Sockets...............:.............................. 10

Radiotron Prongs........................................................ 10

Loose Volume Control Contact Arm.......... 11

Adjustment for Slack Drum Control........ 11

Mechanical Hum......................................................... 12

Broken Condenser Drive Cable........................ 13

Loudspeaker Polarity .

Uncontrolled Oscillation

Distorted Reproduction

Audio Howl ......................

Acoustic Howl ........

Hum ............................

Line Control Switch ............

Wiring Cable .............................

Pilot Lamp and Canopy

Filter Condensers ..................

Voltage Readings ..................

Grid and Plate Voltages

Heating of Cabinet ...............

Continuity Tests .....................

Page

13

. 14

.... 15

.. I5

.... 16

... .16

......18

..... 19

..... 19

..... 20

..... 20

..... 21

..... 22

..... 23

Page

Replacing Volume Control ........................................... 24

Replacing Radio Frequency Coils................................... 25

Replacing Radiotron Gang Sockets................................. 26

Replacing Main Tuning Condensers and Drive …...... . 26

Replacing Large By-Pass Condensers............................. 27

Replacing Audio Transformers ....................................... 28

Replacing Output Transformer........................................ 28

Page

28

29

30

30

31

31

31

Replacing Condenser Drive Cable.........

Replacing Dial Scales............................................

Replacing Power Cable................................

Replacing Filter Condenser Assembly....

Replacing Either Power Transformer or Filter Reactor

Replacing Terminal Strip

Replacing Miscellaneous Parts in S.P.U....

R F. Transformer Connections...................................24

By-Pass Condenser Connections................................25

A. P. Transformer Connections..................................26

Output Transformer Connections...............................26

Replacing Dial Scales ...............................................27

Color Scheme of Power Cable Connections………. 29