2

Drawing No. LP0907 Revised 11 2023

Shock to IEC 68-2-27: Operational 40 g (10 g, modules w/

relays)

Operating and Storage Humidity: 0 to 85% max. RH non-

condensing

Altitude: Up to 2000 meters

Installation Category II, Pollution Degree 2 as defined in IEC/EN

60664-1

CERTIFICATIONS AND COMPLIANCES:

CE Approved

EN 61326-1 Immunity to Industrial Locations

Emission CISPR 11 Class A

IEC/EN61010-1

RoHS Compliant

ATEX/UKEX Approved

II 3 G Ex ic nA IIC T4 Gc

II 3 D Ex tc IIIC T135°C Dc

DEMKO 14 ATEX 1387X

EN 60079-0, -11, -15, -31

UL23UKEX2879X

IECEx Approved

Ex ic nA IIC T4 Gc

Ex tc IIIC T135°C Dc

IECEx UL 15.0035X

IEC 60079-0, -11, -15, -31

India PESO Approved:

A/P/HQ/MH/104/7441 (P549599)

UL Listed: File #E302106

UL Hazardous: File #317425

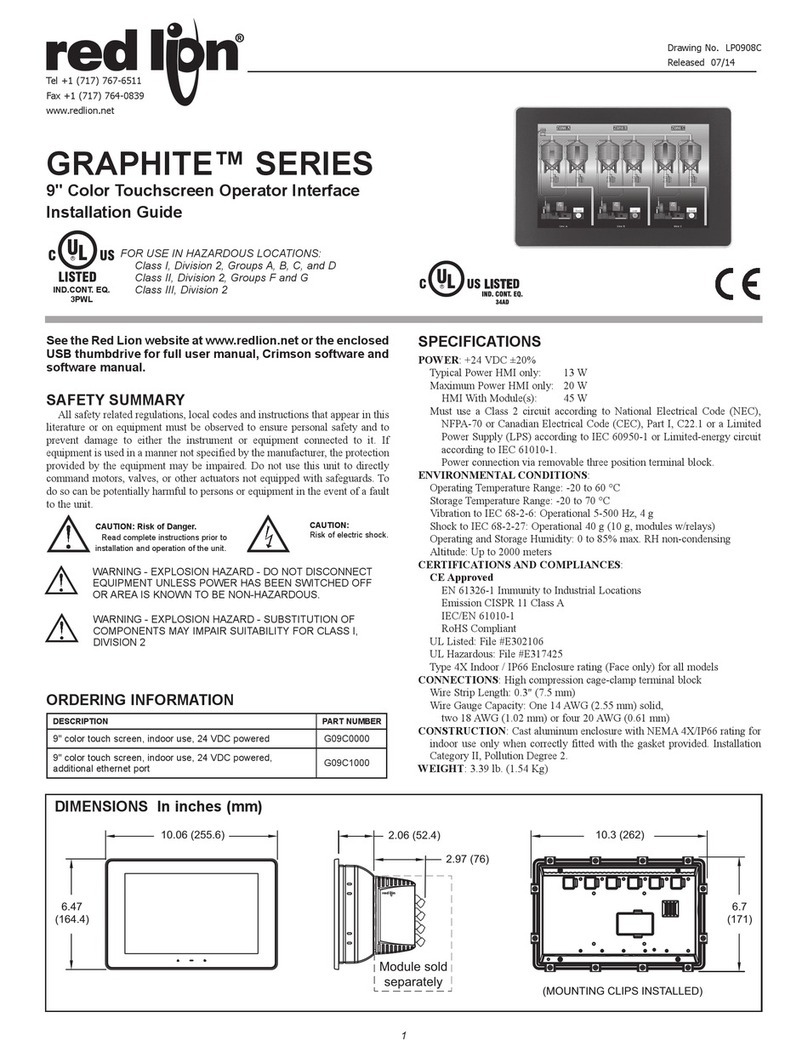

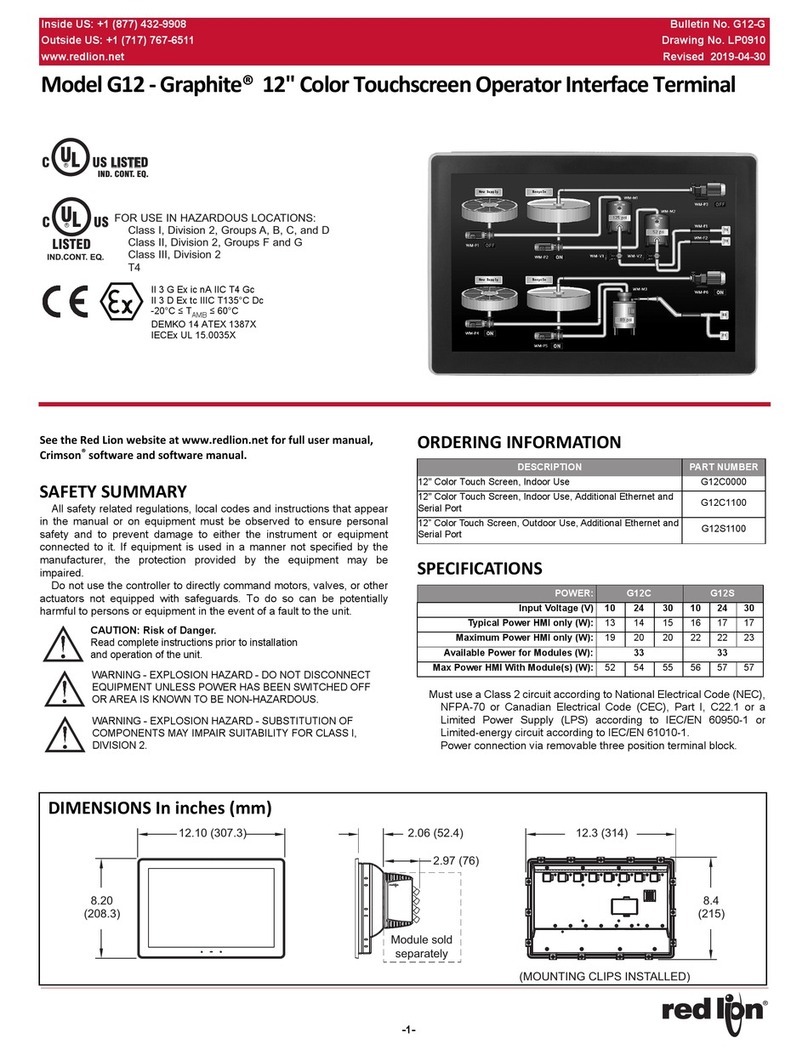

Type 4X Indoor / IP66 Enclosure rating (Face only) for all models

Type 4X Outdoor Enclosure rating (Rear of unit) for G07Sxxxx

models

IP20 Enclosure rating (Rear of unit)

ABS Type Approval for Shipboard Applications

CONNECTIONS: High compression cage-clamp terminal block

Wire Strip Length: 0.3" (7.5 mm)

Wire Gauge Capacity: One 14 AWG (1.63 mm) solid,

two 18 AWG (1.02 mm) or four 20 AWG (0.81 mm)

CONSTRUCTION: Cast aluminum enclosure with NEMA 4X/

IP66 rating when correctly fitted with the gasket provided.

These devices have only been evaluated for low risk of

mechanical impact.

WEIGHT: 2.26 lb. (1.03 Kg)

OPERATOR INTERFACE INSTALLATIONS

MOUNTING INSTRUCTIONS

For hazardous location installation, the following shall be taken

into consideration.

- When used in a Zone 22 environment, the device shall be

panel mounted in at least Zone 22 ATEX/IECEx/UKEX-

Certified tool accessible enclosure with a minimum ingress

protection rating of at least IP64 as defined in IEC/EN 60529.

- When used in a Zone 2 environment, the device shall be panel

mounted in at least Zone 2 ATEX/IECEx/UKEX-Certified tool

accessible enclosure with a minimum ingress protection rating

of at least IP54 as defined in IEC/EN 60529.

- This device is open-type and must be mounted in a suitable

dust-tight end-enclosure in accordance with articles 500

and 502 of the NEC and positioned so only the face of the

display is exposed.

- Must be wired using Division 2 wiring methods as specified

in article 501-4(b), 502-4(b), and 503-3(b) of the National

Electric Code, NFPA 70 for installation within the United

States, or as specified in section 19-152 of Canadian

Electrical Code for installation in Canada.

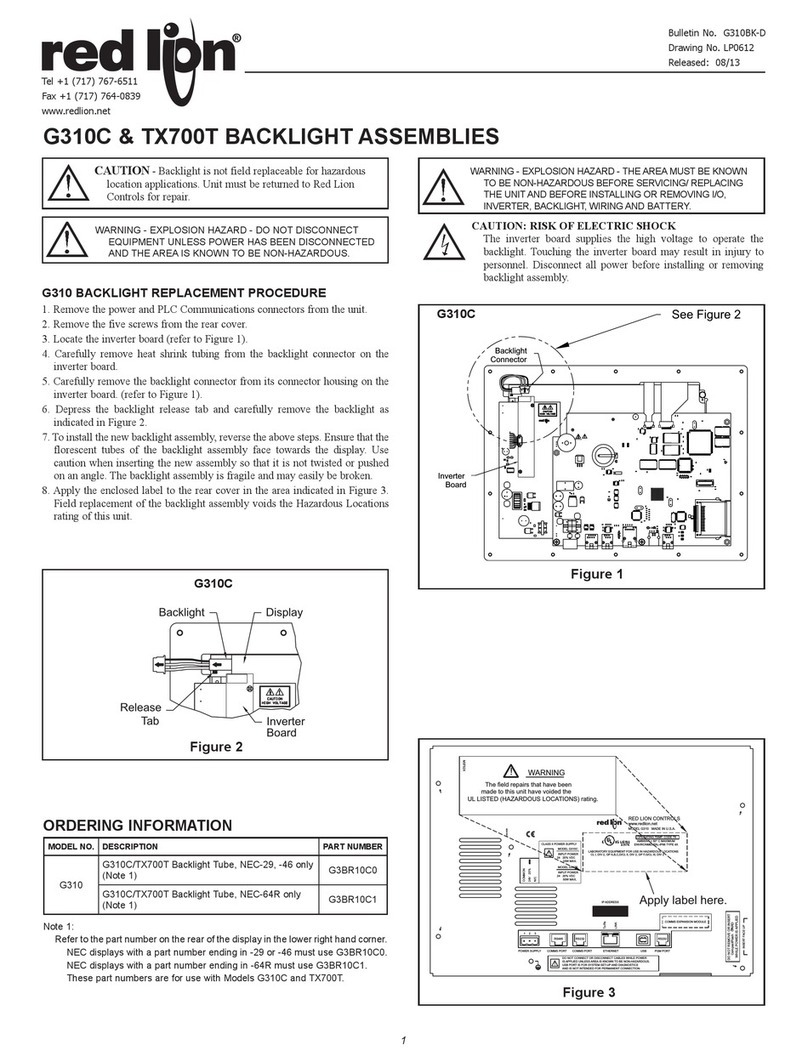

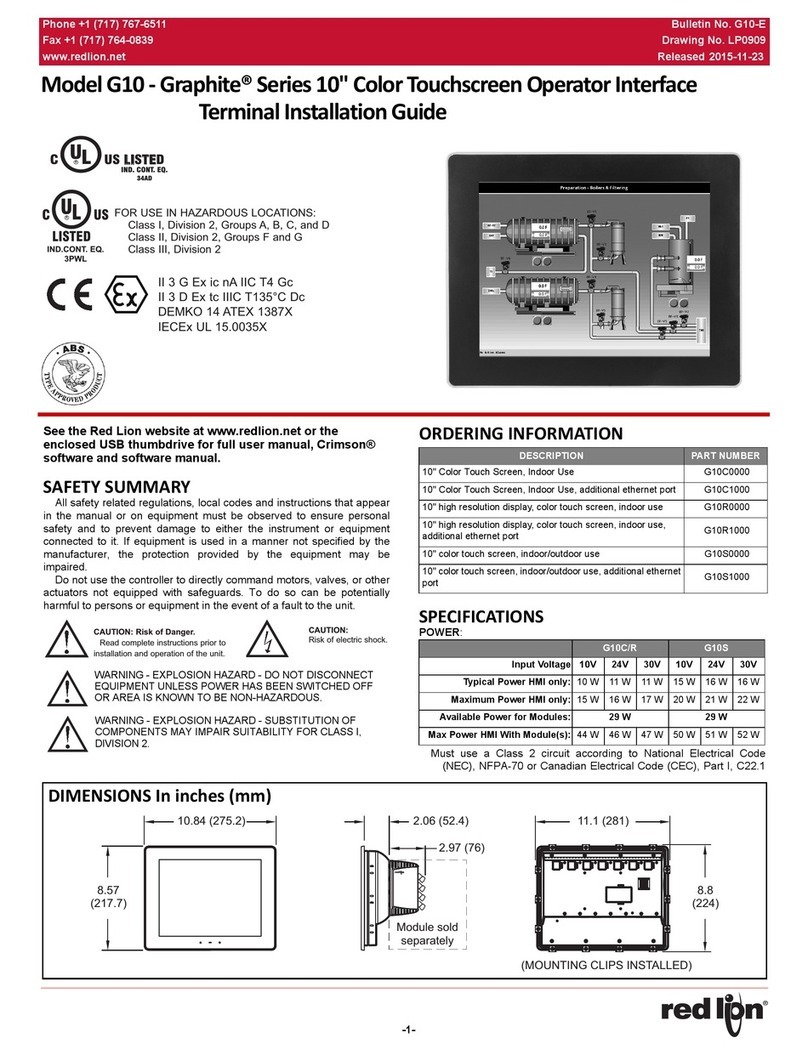

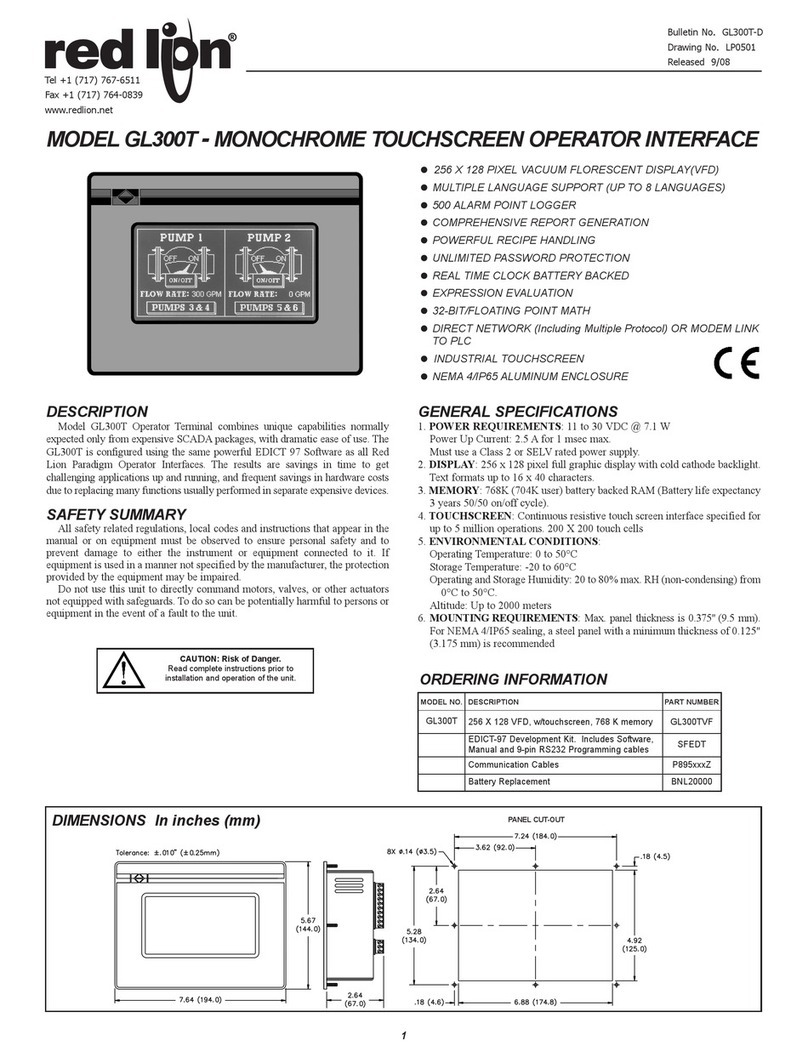

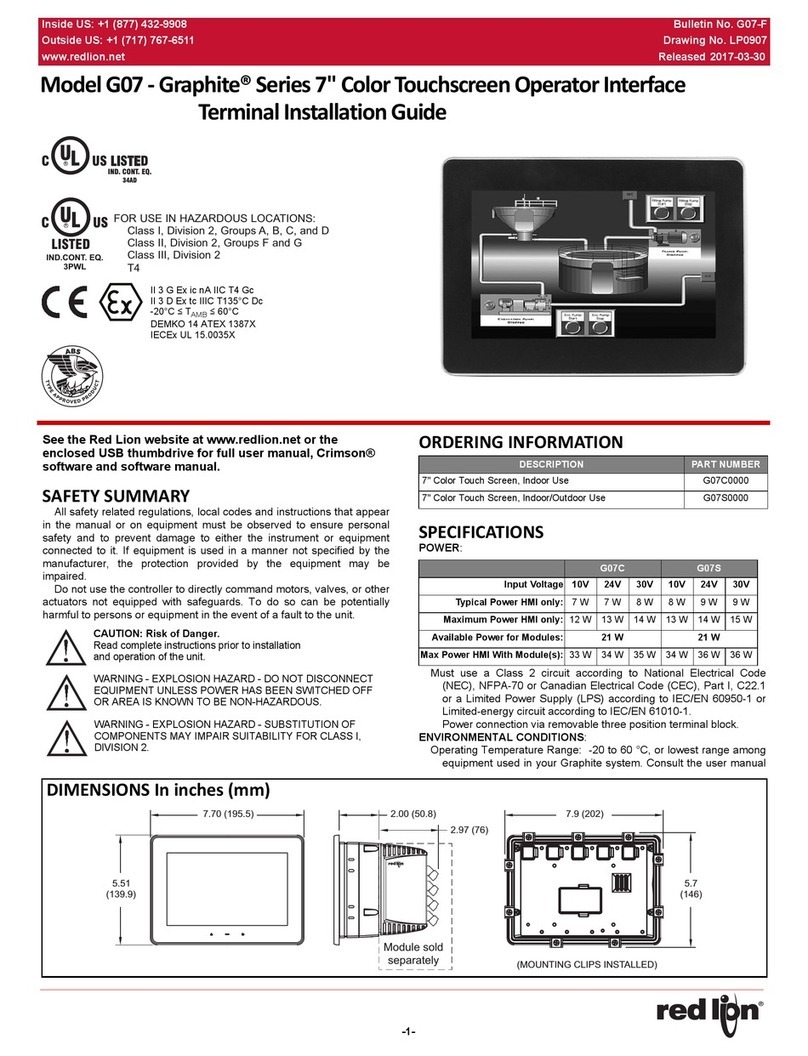

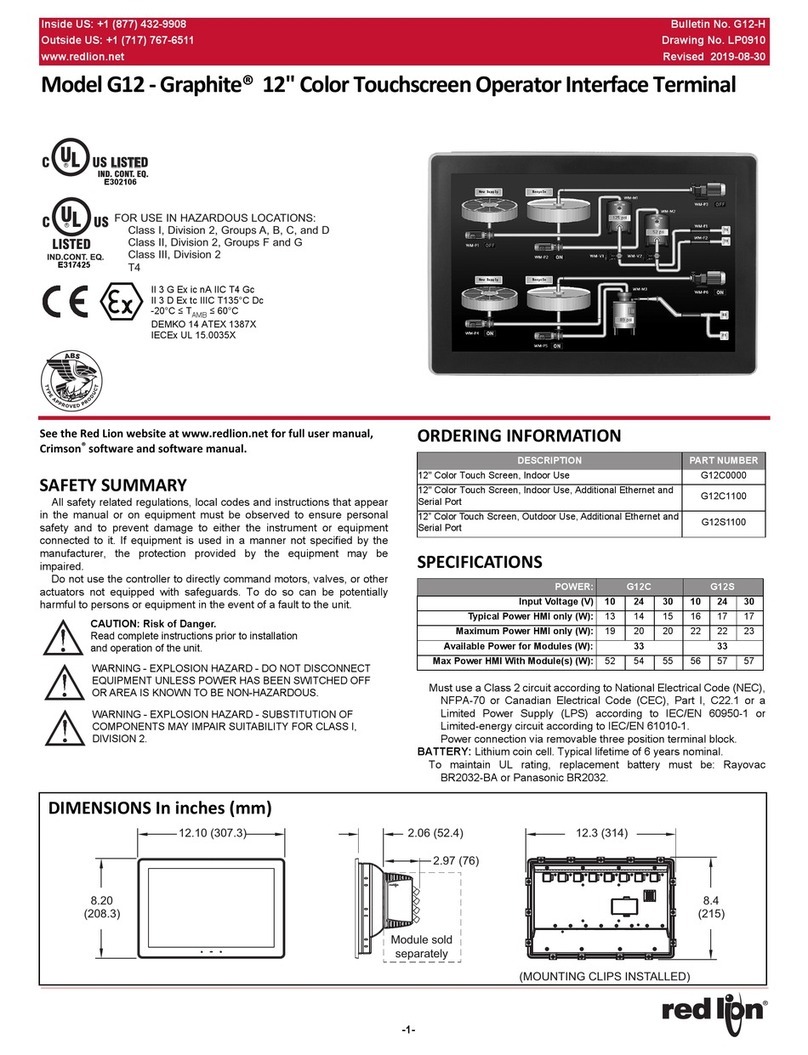

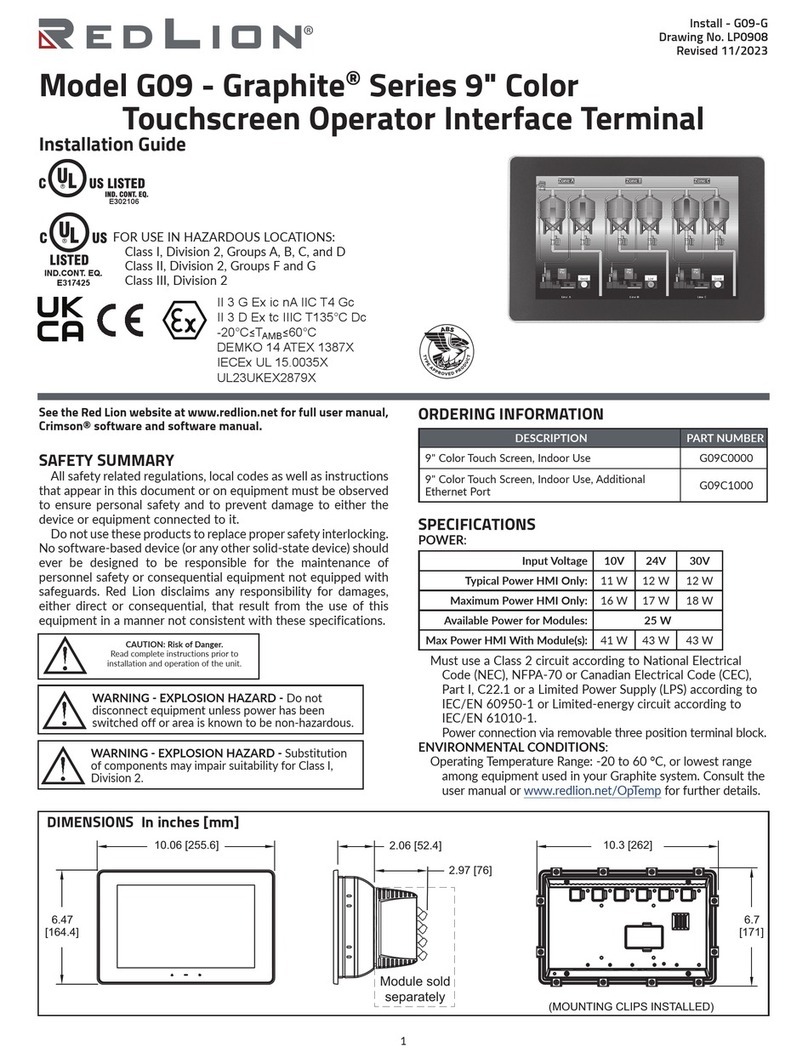

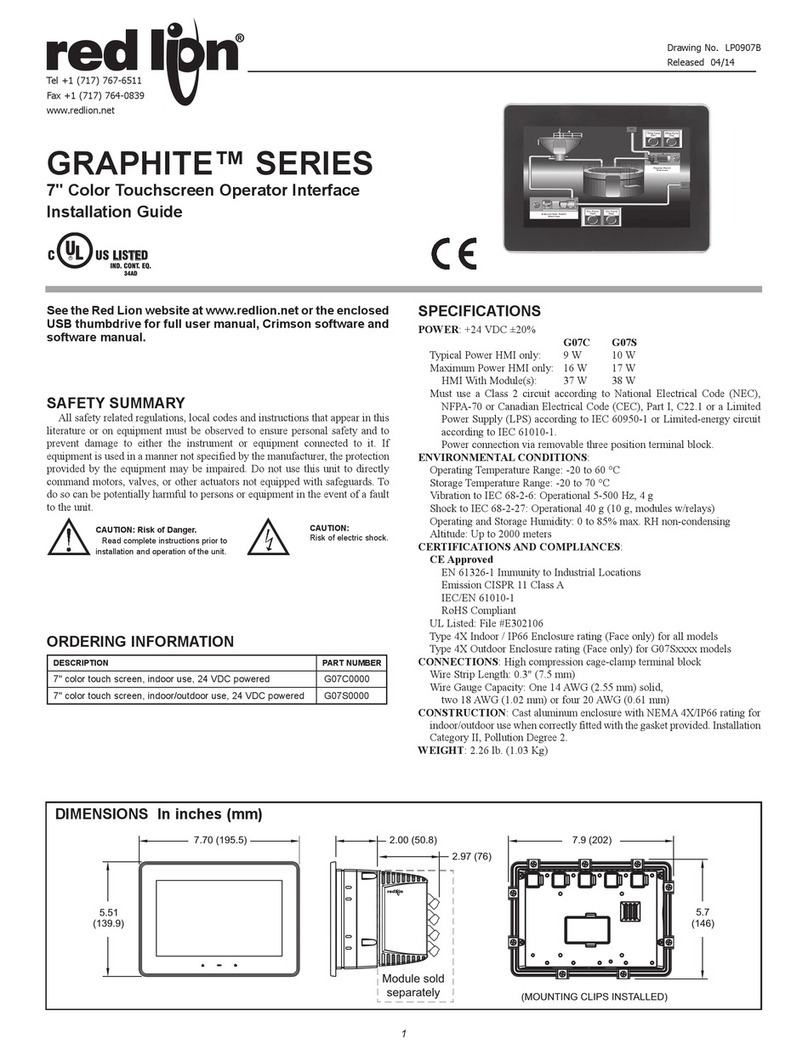

PANEL CUT-OUT

CONNECTING TO EARTH GROUND

The third pin of the power connector of the G07 is chassis

ground for the unit. Your unit should be connected to earth

ground. Steps should be taken beyond connecting to earth

ground to eliminate the buildup of electrostatic charges.

The chassis ground is not connected to signal common of the unit.

Maintaining isolation between earth ground and signal common is

not required to operate your unit. But, other equipment connected

to this unit may require isolation between signal common and earth

ground. To maintain isolation between signal common and earth ground,

care must be taken when connections are made to the unit. For

example, a power supply with isolation between its signal common

and earth ground must be used. Also, plugging in a USB cable may

connect signal common and earth ground.1

1USB’s shield may be connected to earth ground at the host.

USB’s shield in turn may also be connected to signal common.

This operator interface is primarily designed

for through-panel mounting. Four VESA mount

tapped screw-holes (M4 x 0.7, 5 mm deep) are

present on the rear of the panels to allow for stand

or wall mounting. Care should be taken to remove

any loose material from the mounting cut-out to

prevent that material from falling into the operator

interface during installation. A gasket is provided to

enable sealing to NEMA 4X/IP66 specification. To

maintain the IP66 rating of the panel, an equivalently

IP rated enclosure should be used. Install the

mounting clips provided and tighten to 6.0 pound-

force inch [96 ounce-force inch] (0.68 Nm) evenly

for uniform gasket compression.

Provisions should be made to prohibit the

product from being exposed to UV radiation while

in use. Care should be taken not to rub or buff the

touchscreen surface in a way that might cause the

accumulation of static charges.

FOR THICKER PANEL

INSTALLATIONS

2.95 (75)

2.95

(75)

1.73

(44)

VESA MOUNT (MIS-D 75) DIMENSIONS

4.869

(123.7)

7.060 (179.3)

4X R.10 (2.5)

MAX.

All tolerances ±.059" (±1.5 mm)