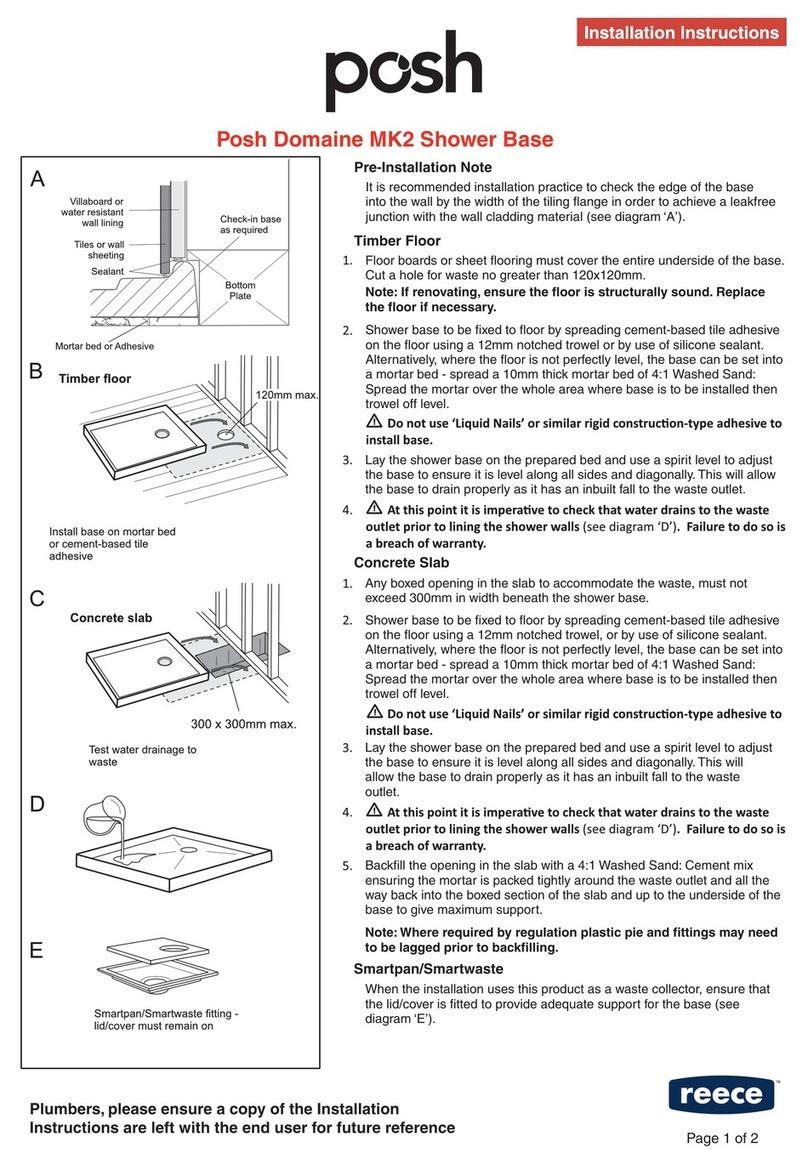

INSTALLATION INSTRUCTIONS

Vanity should be installed by a qualified, licensed trades person.

Vanity Fitting Instructions

•Prior to installation it is important to inspect the vanityto ensure no damagehas occurred in transit. If damage

has occurred, or a visible defect exists, do not proceed with installation and advise supplier immediately. No

warrantyclaim for damage will be accepted if the vanity is installed.

•It is recommended that the Solid Surface Top is protected duringinstallation.

Please Note: Manufacturer will not be liable for the cost of installation or removal of the vanity and the warranty

will be voided if damage occurred during or after installation.

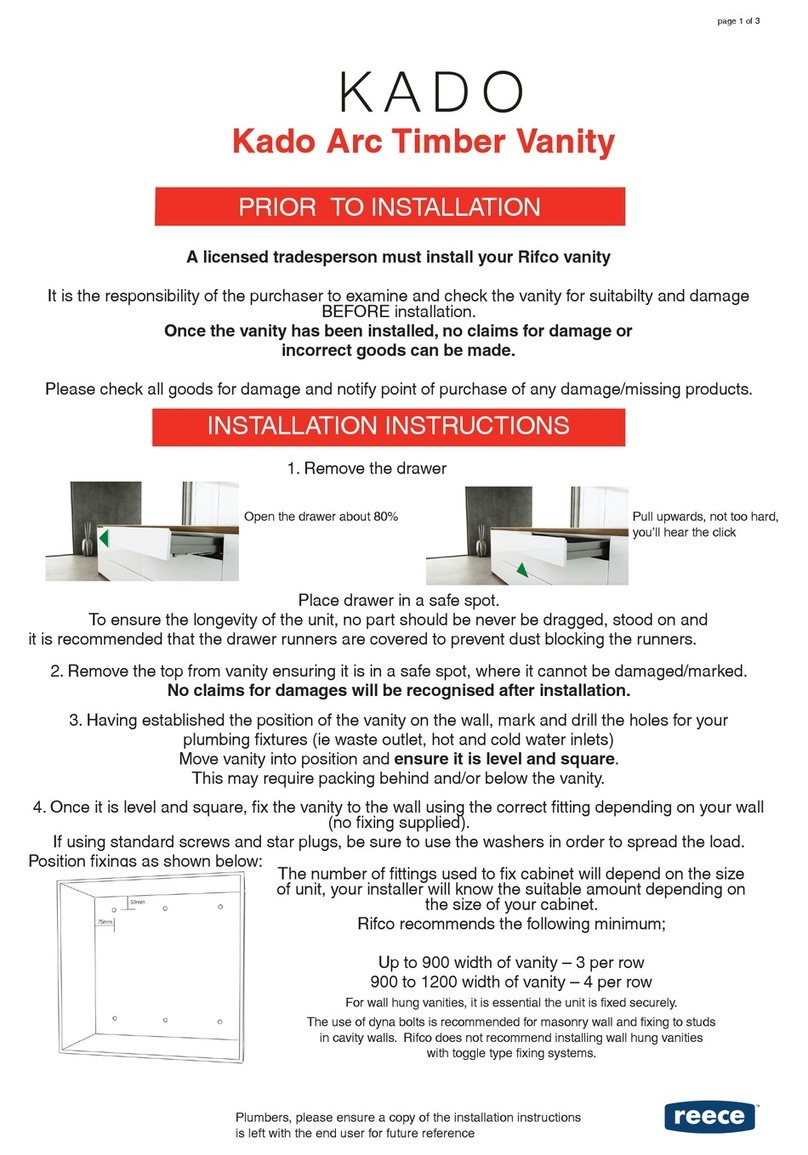

• Remove drawers (refer to Drawer Installation and Adjustment Instructions)

• Mark base and back of the vanity for drillingto allow for plumbing pipes.

•Drill holes for pipes with appropriate size hole saws.

• Position vanity over pipes in correct position.

•It is recommended that the vanitysit on a length of aluminium angle securely fastened to the wall

•Check with spirit level that the vanity is completelylevel.

• Screw vanity to the wallthrough back of thevanity, ENSURING SCREWS ARE FIXED TO STUDS. Allow

enough fixing points at thetop and bottom of the back panel to sufficiently secure the unit to the wall.

• All edges where vanity top and cabinet meet wall and floor are to be properly sealed with bathroom grade sili-

cone to prevent water penetration. Materials used in construction are water-resistant not waterproof. Care must

be taken to dry any spillage or leakage of water which may gain access to the cabinet when fitting.

• Replace drawers (refer to Drawer Installation and Adjustment Instructions).

Recommendation for Plumbing

Wasteshould not be over tightened to avoid stress on basin and top.

PLUMBING SETOUT INSTRUCTIONS

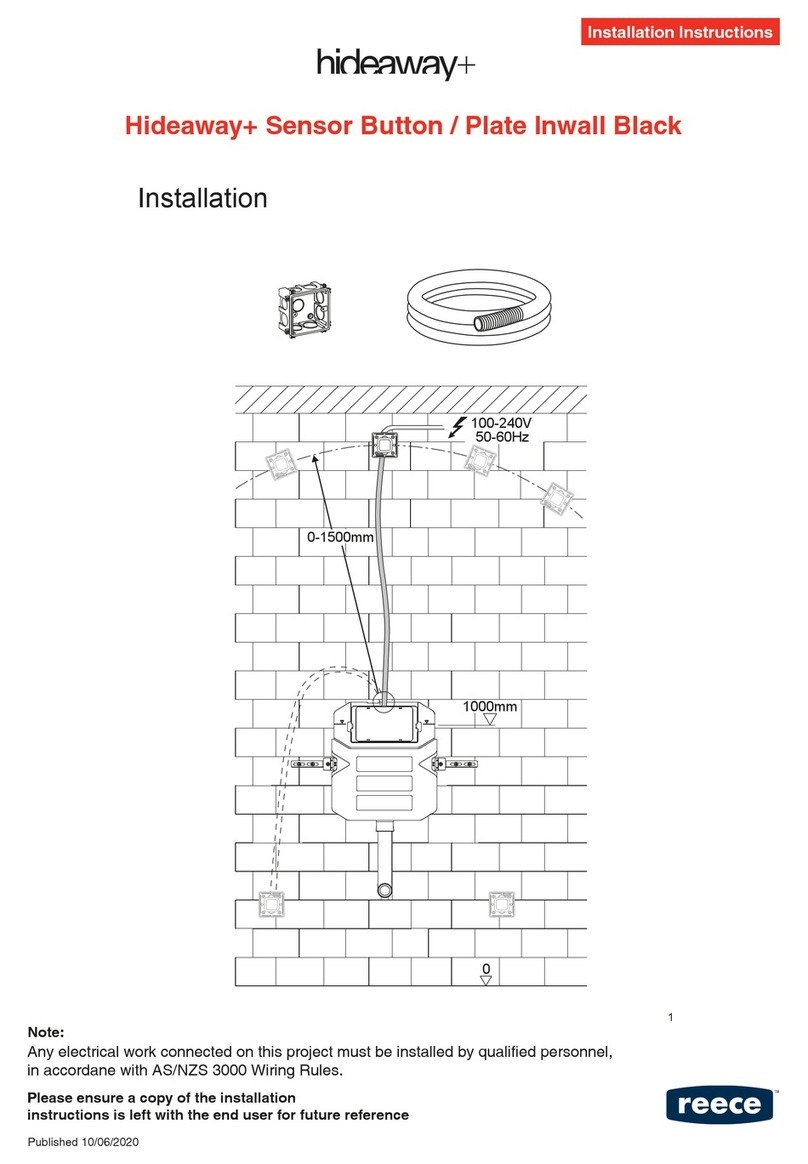

1. Diagrams below show wall positions of 40mm waste pipe , hot and cold outlets (if required).

Note diagrams show set outs for 750, 1200 and 1500 left hand basin.

For right hand basin use mirror opposite.

2. Use 40mm plug and waste,non overflow with 40mm Short Inlet P Trap (both not supplied)

3. Plumbing set outs for customised sizes:

751 - 850 same as for 750set out

1000 - 1300 sameas for 1200set out

1400 - 1499 sameas for 1500 set out

For plumbingset outs of customised 1751-2000mm double basin contact manufacturer .

If using a basin mixer, hot and cold hoses should be bracketed to the side or back of the vanity so as not to

impede operation of the drawer.

Plumbers, please ensure a copy of the installation

instructions is left with the end user for future reference

ISSY GLIDE TWIN VANITY UNIT

page 7 of 8

4.

5.

GLIDE RISE 1500

245255

260

1500 500

GLIDE RISE 1750 DOUBLE BASIN

245255

260 260

1750 500

85

85

85

85 85

85

450450

ISSY GLIDE TWIN VANITY UNIT

page 3 of 8