Series SW/TW4000 Welding Hose Reels

Page 2 www.reelcraft.com

INSTALLATION INSTRUCTIONS

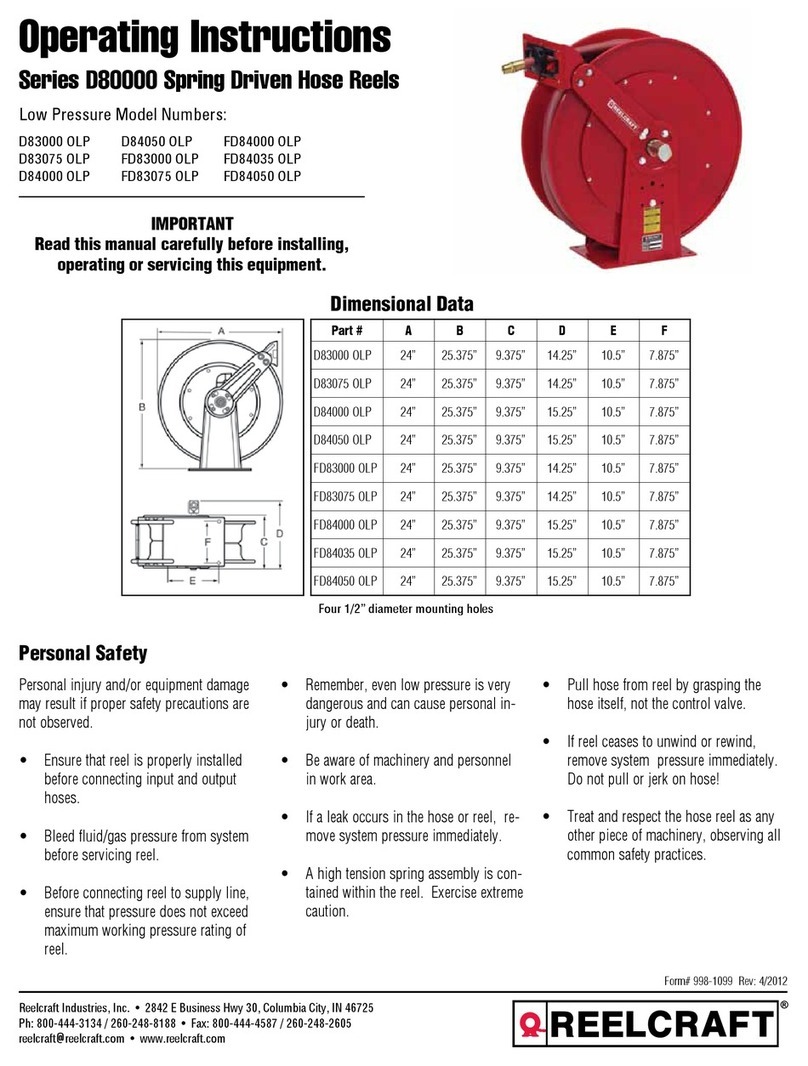

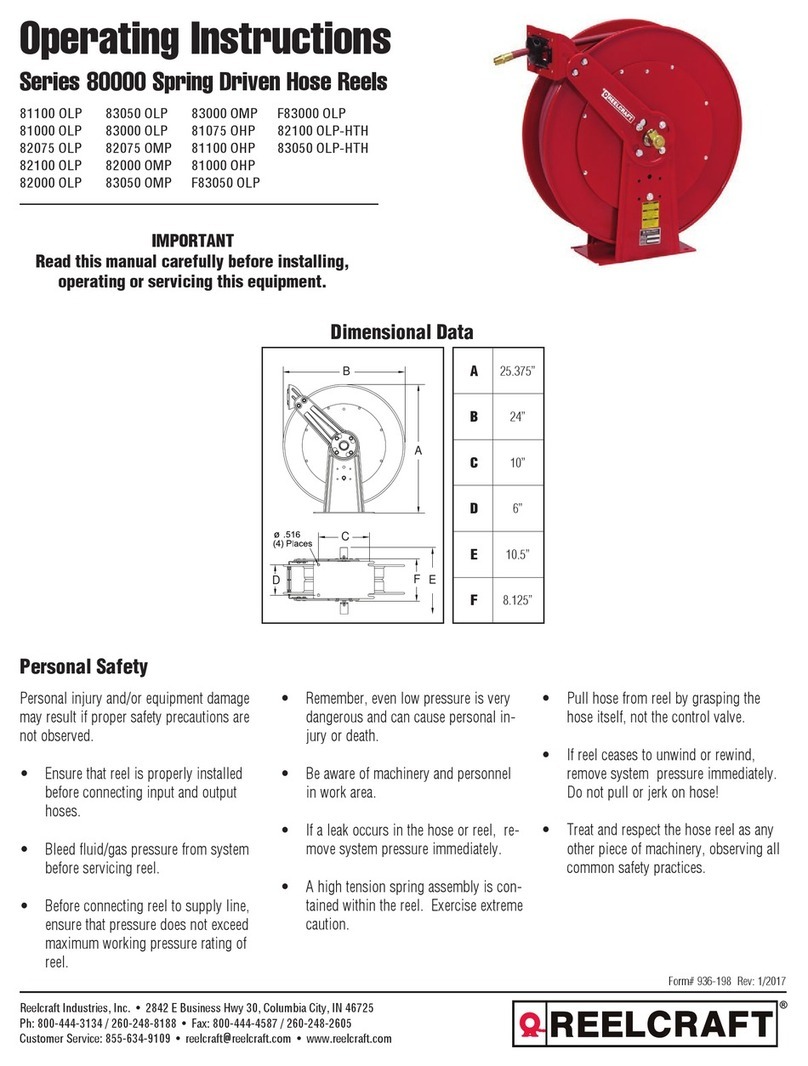

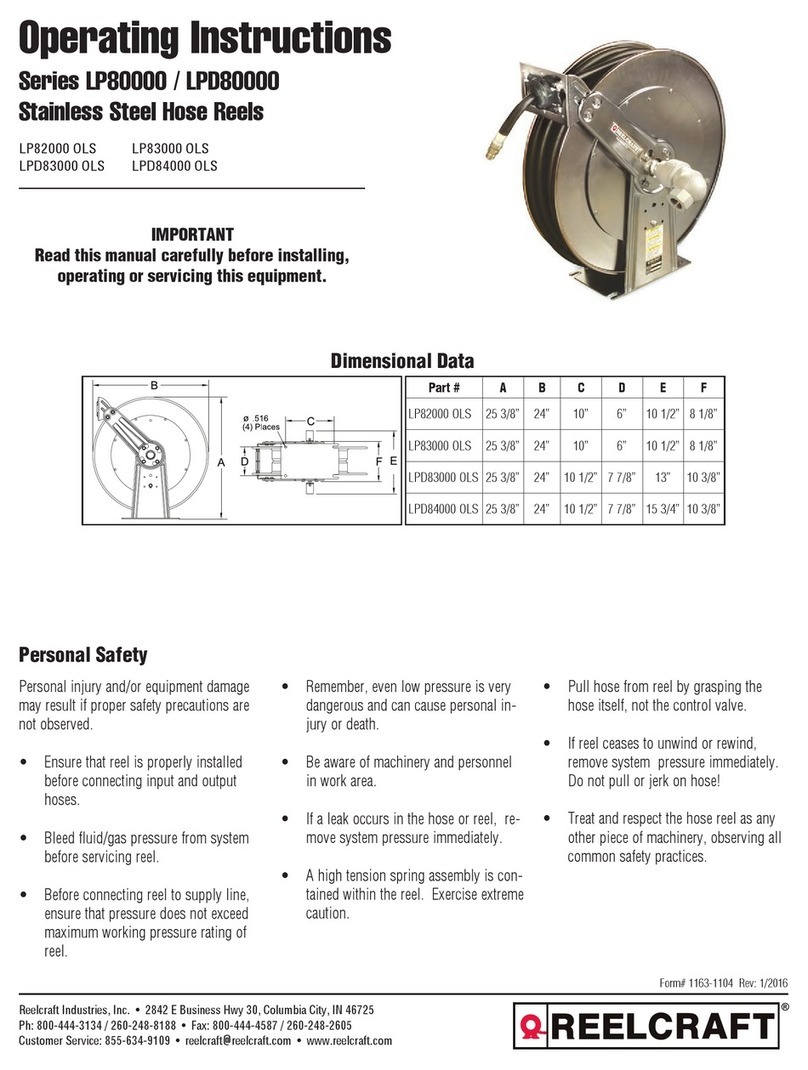

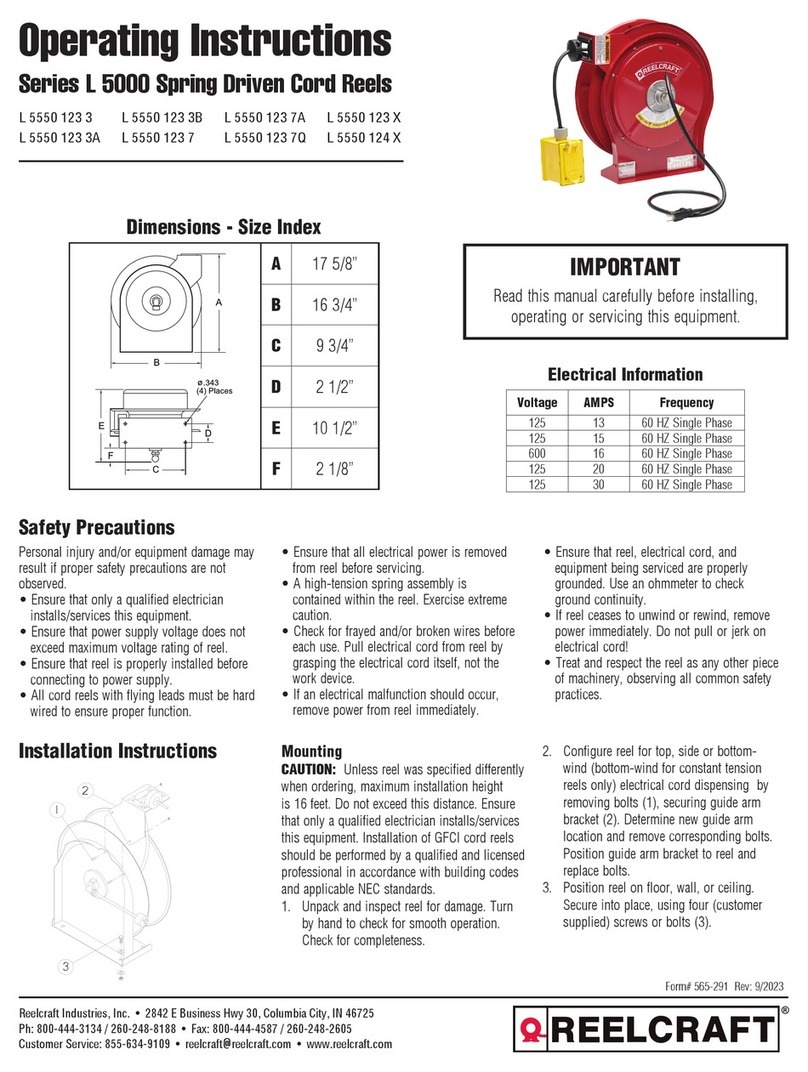

MOUNTING

Caution: Unless reel was specified differently when ordering,

maximum installation height is 10 feet. Do not exceed this dis-

tance. Observe all applicable NEC, OSHA & local codes when

installing this equipment.

1. Unpack and inspect reel for damage. Turn by hand to

check for smooth operation. Check for completeness.

2. Configure reel for top, side, or bottom-wind hose dispens-

ing by removing bolts (or nuts) (1) securing guide arm

bracket (2).

3. Determine new guide arm bracket location and remove

corresponding bolts, (or nuts). Position guide arm bracket

to reel and replace bolts (or nuts).

4. Position reel on floor, wall or ceiling. Secure into place

using four (customer supplied) screws or bolts (3).

INSTALLING THE INPUT HOSES

Caution: Apply teflon tape to all input connections to insure

a proper seal.

INSTALLING THE OUTPUT HOSES

Caution: Use extreme caution; reel under tension, avoid

releasing latch mechanism.

1. Manually turn spool assembly until spring is tight, back

off three turns, then latch.

2. Route output hoses through guide bracket.

3. Using a wrench, firmly hold on to output fittings on swivel

while tightening the hose connector.

SERVICE INSTRUCTIONS

User servicing of the reel is limited to replacing the input/

output hoses or swivel only. Refer all other repairs to an autho-

rized service person or directly to Reelcraft Industries, Inc.

Failure to do so can result in personal injury and/or equipment

damage and may void the warranty.

Caution: Rewind hose on reel, then bleed pressure from sys-

tem before performing the following procedures.

1. Replace hoses in accordance with procedures given in

“Installation Instructions” section of this manual.

REPLACING THE SWIVEL

Caution: Remove supply line pressure before performing the

following procedure.

1. Remove supply line from swivel.

2. Remove swivel assembly from inlet shaft.

3. Apply thread sealant to threaded connection and re-install

swivel assembly to inlet shaft by reversing steps 1 & 2.

ADJUSTMENTS

Caution: Use extreme caution; reel under tension. Avoid

releasing latch mechanism. If necessary, adjust spring tension

of reel by adding or removing wraps of hose from spool, one

wrap at a time, until desired tension is obtained. Add wraps

to increase tension. Remove wraps to decrease tension. When

adding wraps of hose, be careful not to exceed the winding

mechanisms spring capacity. Add just enough wraps of hose to

achieve the desired tension. Damage to the winding mechanism

will result if spring is over-tensioned.

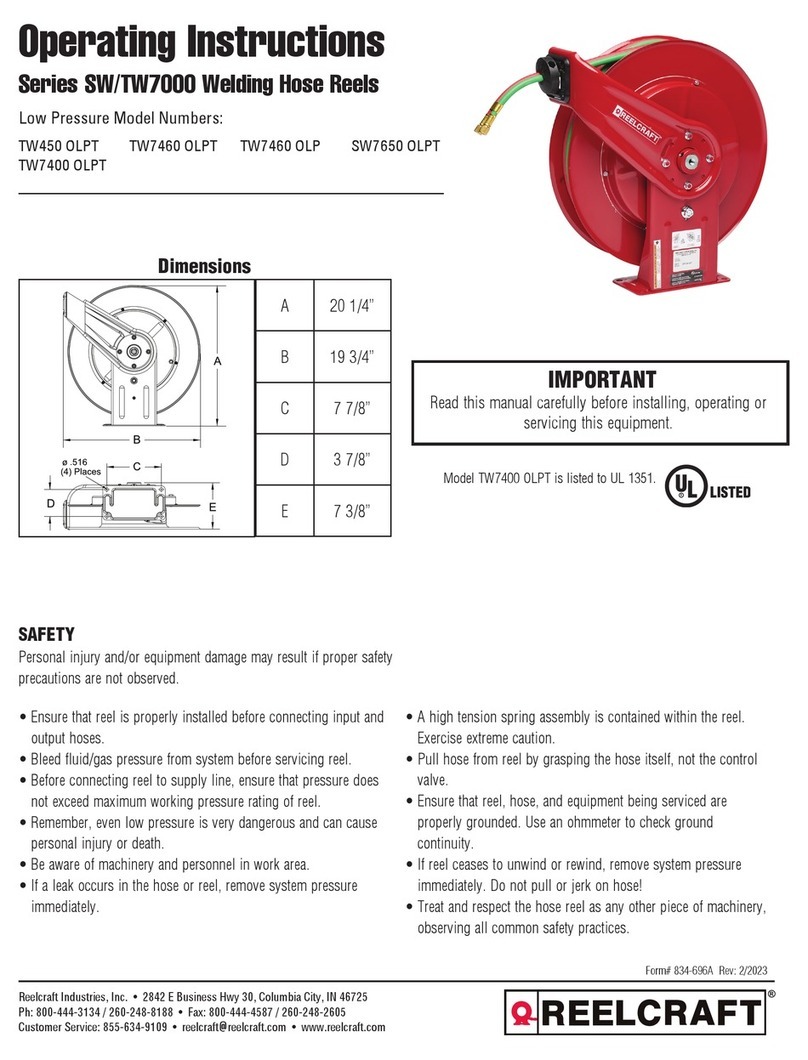

Acetylene/fuel gas

inlet 1/4” FPT

(Red)

Oxygen

inlet 1/4” FPT

(Green)

2

1

3

Acetylene/fuel gas

inlet 1/4” FPT

Series TW

Series SW