3 │

1 - Description

PSWF Thermal Stores are intended for storing and subsequent distribution of thermal energy from solid-fuel fired boil-

ers, heat pumps, solar collectors, electric boilers etc. This thermal store shall be always connected to a sealed heat-

ing circuit. It is fitted with two flanges ready to receive suitably sized tube heat exchangers. Mating flanges for heat

exchangers with either G 1” or G ¾” connections are available as an option. When no heat exchanger is installed, a

blind flange shall be used (option).

These heat exchangers are made of finned copper tubes that feature larger surface area and better heat transfer.

The lower heat exchanger usually connects to a solar system and the upper one is used for DHW heating (continu-

ous) which limits significantly the risk of Legionella bacteria formation. The tanks are also fitted with nine G 6/4“ side

sleeves to connect heat sources, four G ½“ ones for sensor sheaths and one G ½“ sleeve for a safety valve. El. heat-

ing elements can be installed directly into the 6/4” sleeves.

1.1 - Models

Seven models of 285, 479, 661, 809, 932, 1509 and 2010 l capacity.

1.2 - Tank protection

The inner surface has no finish, no anticorrosion protection, the outer surface is lacquered in gray.

1.3 - Thermal insulation

Tank insulation is available as a separate item, installed on the tank on the spot for easier handling. The insulation is

made of 100 mm thick flexible polyurethane foam and fitted with a zippered PVC surface layer.

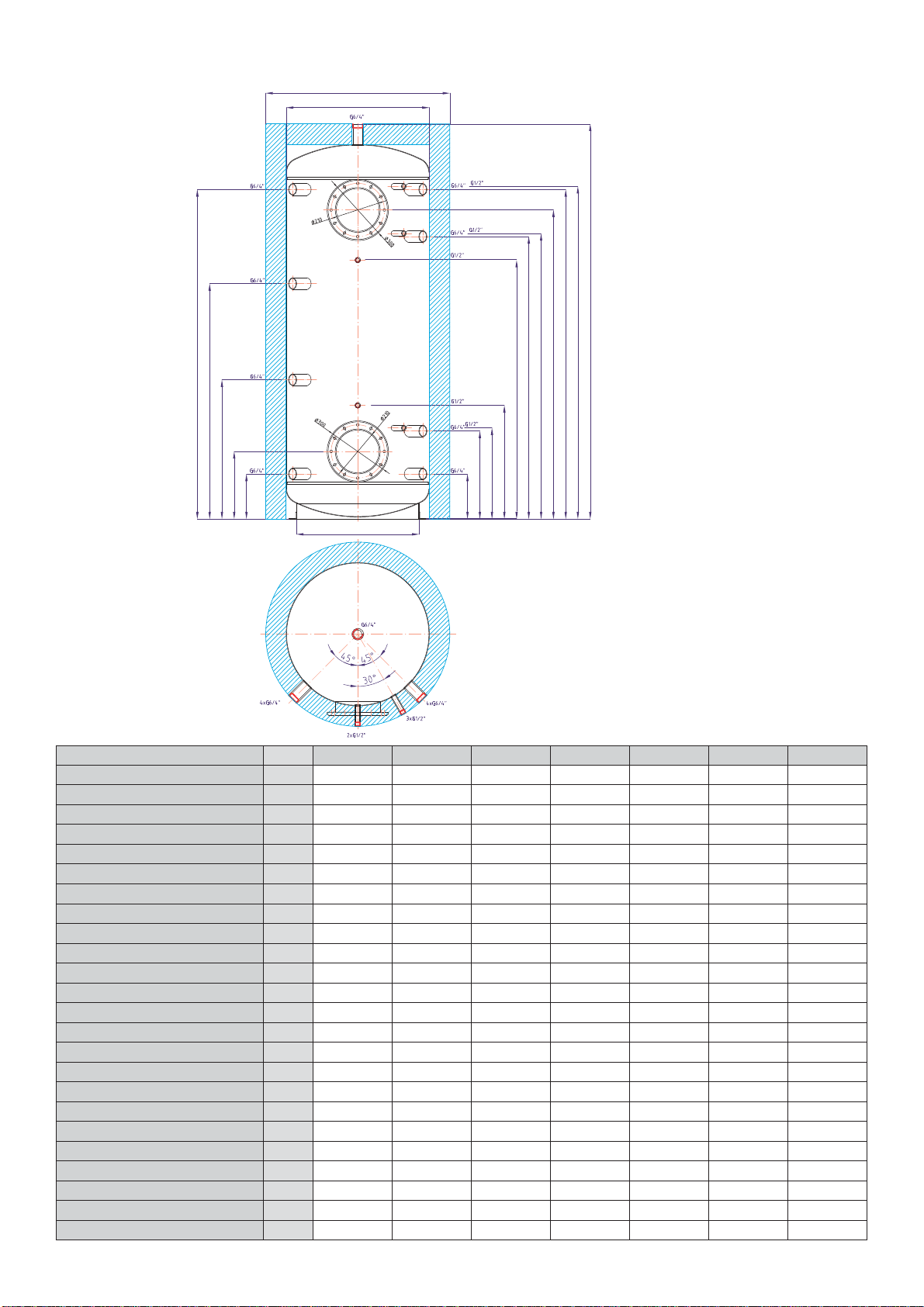

1.4 - Connection points on the tank

2 flanges with 210 mm inner diam.

8 side sleeves in a 90° sector, G 6/4” F thread

1 top sleeve, G 6/4” F thread

4 side sleeves for sensor sheaths, G ½” F thread

1 side sleeve for a 3 bar safety valve (included), G ½” F thread

1.5 - Packing

Tanks are delivered standing, each screwed to its pallet, packed in bubble wrap.

Included in the package are gaskets, bolts for the flange and a 3 bar safety valve with G ½” F thread.

2 - General Information

This Owners Manual is an integral and important part of the product and must be handed over to the User. Read care-

fully the instructions in this Manual as they contain important information concerning safety, installation, operation and

maintenance. Keep this Manual for later reference. The appliance shall be installed by a qualified person according to

valid rules and Manufacturer‘s Instructions.

This appliance is designed to accumulate heating water and distribute it subsequently. It shall be connected to a

heating system and heat sources. The equipment is suitable also for continuous water heating. In such a case, the

customer needs to buy a suitably sized heat exchanger (available as accessory) and have it installed into the upper

flange.

Using the thermal store for other purposes than above described (e.g. as a DHW tank) is forbidden and the

manufacturer accepts no responsibility for damage caused by improper or wrong use.

The thermal store shall not be used as a DHW tank!