Resetting Procedure For Model LDX,

DDX,EX Dry Systems & Model DDX Type F

Preaction Systems

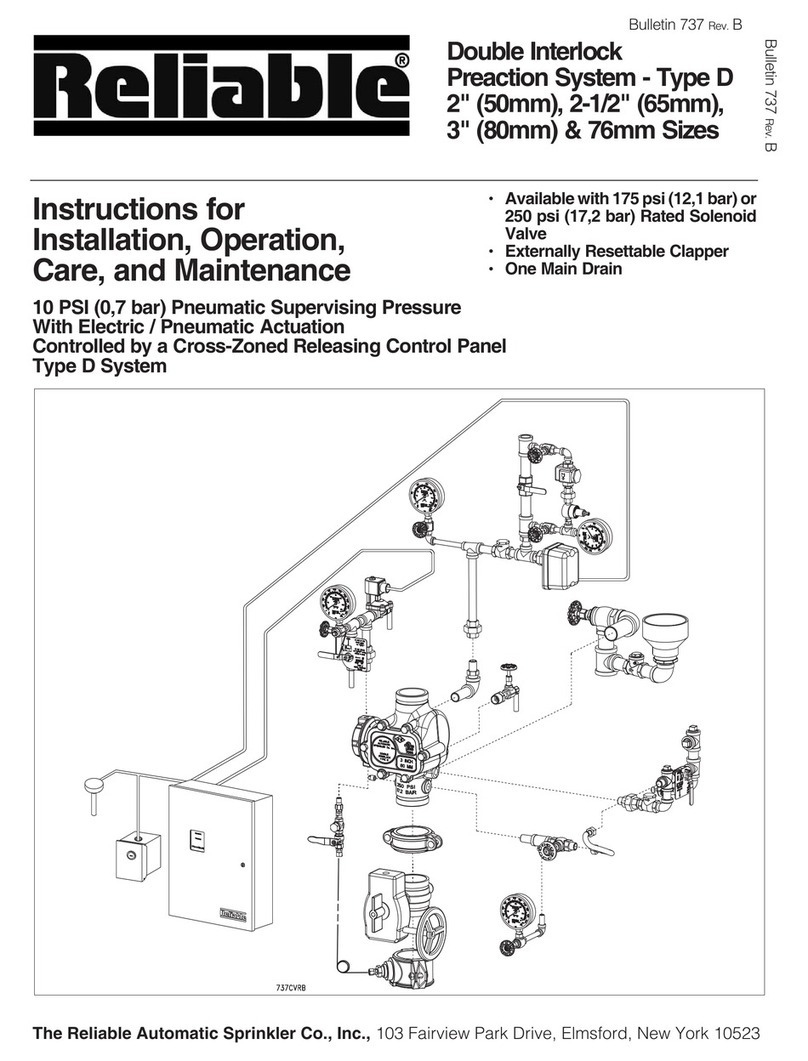

(Refer to Figs. 1, 3, 4, 5 & 6)

1. Isolate the Accelerator by closing valve B, Figs. 3,

4, 5 or 6.

2. Close the air and water supply valves to the deluge

valve. Drain and fully reset the deluge valve in accor-

dance with its technical bulletin.

3. Re-close the main water supply control valve to pre-

vent accidental operation of the system while reset-

ting the Accelerator.

4. Remove the body drain plug from the lower section

of the Accelerator, Item #3, Fig 1.

5. Remove the top chamber drain plug, Item #3, Fig.

1, from the side of the Accelerator. If water is pres-

ent in the top chamber, disassemble the Accelerator,

and clean and dry the top and middle chambers and

diaphragm assembly using a clean lint free cloth. Re-

assemble the Accelerator. Replace the top chamber

drain plug using new thread sealant.

6. Remove the Accelo–Check Body, Item #19, Fig. 1,

and gently lift the Accelo–Check Diaphragm Assem-

bly, Item #22, Fig. 1, to verify venting of the middle

chamber. Carefully reinstall these parts.

7. Partially open valve B, Figs. 3, 4, 5 or 6, gently purg-

ing any water which may be in the trim lines. Close

this valve and replace the. body drain plug from the

lower section of the Accelerator, Item #3, Fig 1.

8. Pressurize the Accelerator by opening valve B, Figs.

3, 4, 5 or 6. The top chamber pressure of the Accel-

erator should equal the system pressure.

9. Slightly open the main water supply control valve.

Close the main drain valve when water flows, then-

fully open the main supply valve. The system is now

ready for service.

Caution

The presence of water in the Accelerator may cause pre-

mature operation. Therefore, it is imperative that after sys-

tem operation, the Accelerator be inspected for any signs

of water in the top chamber and that the Accelerator trim

lines are purged prior to completing the Accelerator reset

procedure. In addition, after system set–up, the prime wa-

ter level must not exceed the dry pipe valve’s prime level

(if applicable). If water is found in the Accelerator, due to

excessive prime level or back drainage, the Accelerator’s

inlet system connection must be relocated to the riser at

least 2 ft. above the dry pipe valve.

10.

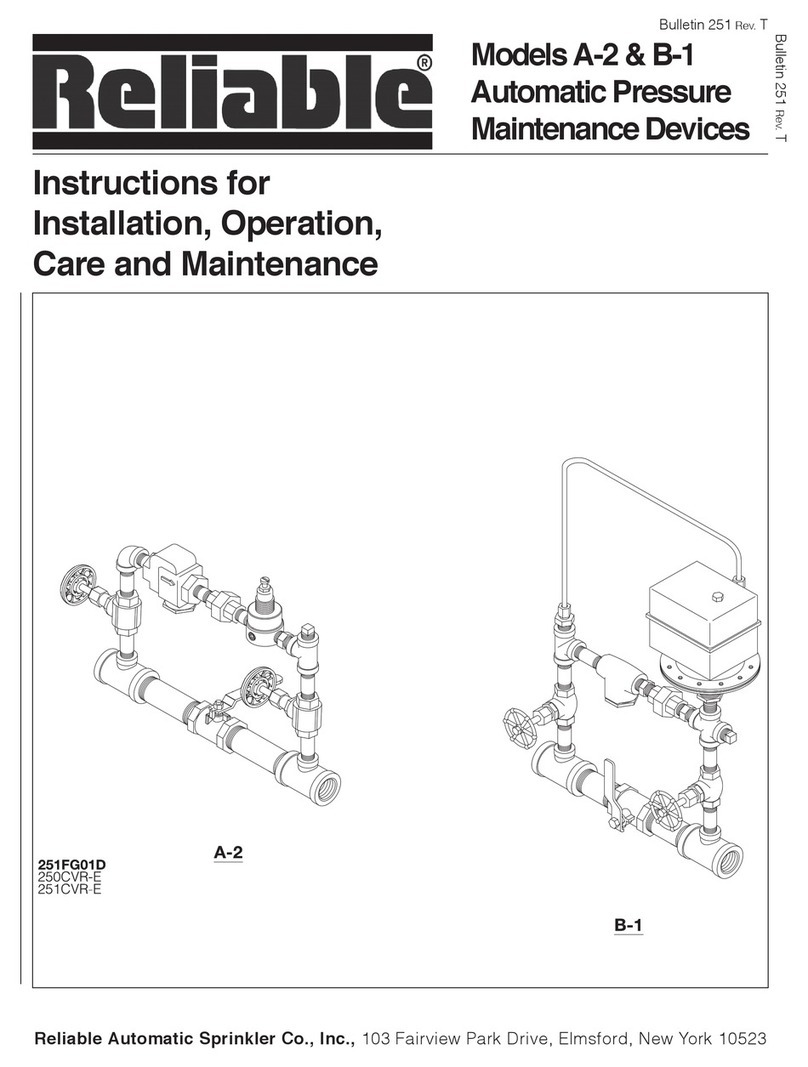

Recommended Periodic Inspections

The following inspections should be performed on the

Model B1 Accelerator on a weekly basis.

1. Check that the correct system air pressure has been

set.

2. Verify that Accelerator’s top chamber pressure and

system air pressure are equal.

3. Verify that the valves located on both the Accelera-

tor’s inlet and outlet lines are in the open position. A

valve located on the Accelerator’s outlet port should

only be present if the Accelerator is connected to

vent into a dry pipe valve’s intermediate chamber.

Otherwise, the Accelerator’s outlet port should vent

to the atmosphere.

4. Check that the prime water level is correct (if appli-

cable).

5. Check for leakage at the ball drip valve, located

above the drain cup. Leakage may indicate the

sealing surfaces in the dry pipe valve require main-

tenance.

Test

The following Accelerator tests should be performed

semi–annually or whenever the Accelerator has been dis-

assembled.

A. Accelerator test without operating the dry pipe valve.

1. Isolate the Accelerator by closing the valves lo-

cated on its inlet and outlet ports.

Model D Dry Pipe Valve, Fig. 2 - Valves A and C.

Model LDX, DDX-LP, EX, DDX Valves, Figs. 3, 4,

5 or 6 – Valve B

2. Loosen the body drain plug, Item #3, Fig. 1 in or-

der to decay the pressure at the inlet of the Accel-

erator. This will simulate a system decay as when

one or more sprinklers open. The Accelerator

should operate.

3. Reset the Accelerator following the instructions

de- scribed in the “Resetting Procedure” sections

of this bulletin.

B. Sensitivity Test (Model D Dry Pipe Valves only)

1. Close the main water supply control valve.

2. Bleed the system air pressure at a rate of 1 psi

per minute by opening the prime level valve lo-

cated on the dry pipe valve.

3. After ten minutes (the air pressure should have

decayed 10 psi) the Accelerator should not have

tripped.

4. Restore the system air pressure and reopen the

main water supply control valve.