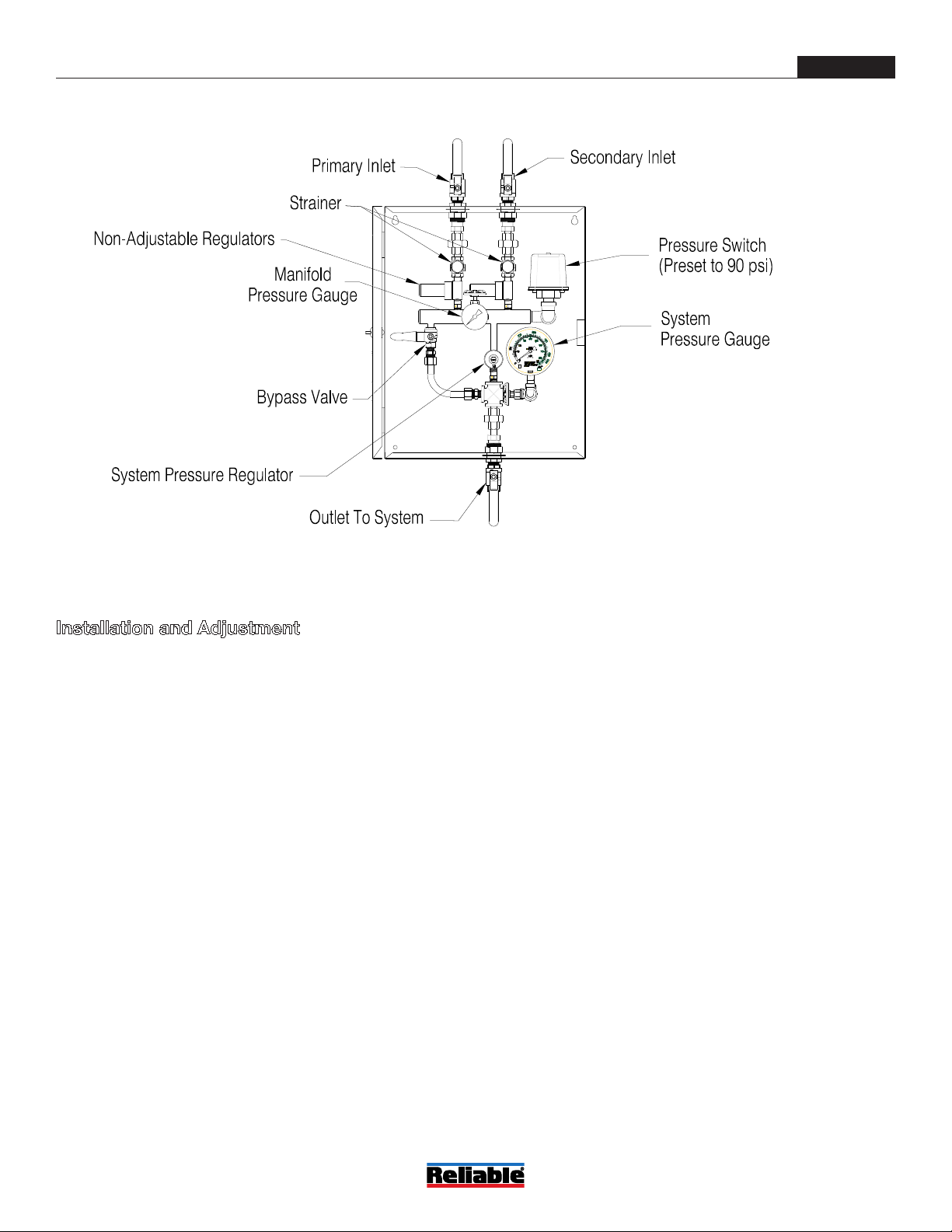

Installation and Adjustment

1. Securely mount the NS-ASAM enclosure to the wall using

the keyhole slots.

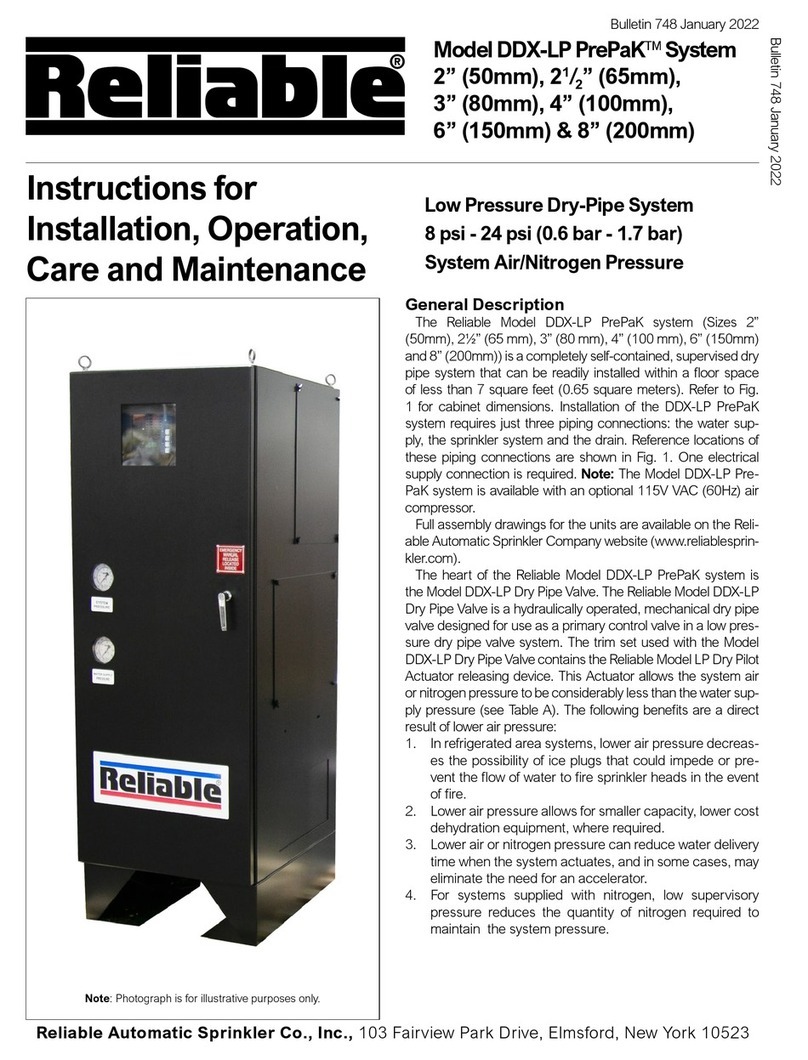

2. Confirm that all valves are closed.

3. Securely mount and properly pipe the primary and sec-

ondary sources of nitrogen or air in accordance with

appropriate local, state, or federal standards.

4. Connect the primary source of nitrogen or air to the prima-

ry inlet of the NS-ASAM and connect the secondary source

of nitrogen or air to the secondary inlet of the NS-ASAM.

5. Connect the NS-ASAM outlet to the port provided for pneu

matic supply to the sprinkler system (see note 1).

6. Before applying pressure to the sprinkler system, turn the

adjustment screw on the System Pressure Regulator within

the NS-ASAM fully counterclockwise.

7. Adjust the primary and secondary sources of nitrogen or

air to a recommended pressure of 120 psi (8.3 bar); the

minimum required inlet pressure is 100 psi (6.9 bar) and

the maximum rated inlet pressure is 250 psi (7.2 bar).

8. Open the Primary Inlet Valve and the Secondary Inlet

Valve.

9. Open the Bypass Valve and the NS-ASAM Outlet Valve to

allow nitrogen or air to flow into the system piping.

10. When the system pressure rises to within 2 psi (0.15 bar)

of the required system pressure, fully close the Bypass

Valve.

11. Slowly turn the adjustment screw of the System Pressure

Regulator clockwise to increase pressure to the level

required by the system. Tighten the lock-nut on the System

Pressure Regulator (see note 2).

12. If desired, supervise the contacts of the Pressure Switch in

accordance with NFPA 72 to provide notification that the

primary nitrogen or air source is depleted. The auxiliary

contacts of the pressure switch may also be supervised to

indicate depletion of the secondary source of nitrogen or

air. When supervising the auxiliary contacts, the primary

contacts of the pressure switch should remain at the

factory setting of 90 psi (6.2 bar) to indicate depletion of

the primary source and the auxiliary contacts should be

adjusted to a pressure setting of approximately 70 psi (4.8

bar).

13. If necessary, adjust the setting of the low-pressure switch

for each system.

14. Use a soap solution at all joints to verify leak-tight connec-

tions.

Notes:

1. When applying more that one system, each system must

have an individual Pressure Maintenance Device.

2. For multiple systems, the NS-ASAM system regulator must

be set a minimum of 5 psi above the highest system pres-

sure required. Use the regulator on the Pressure

Maintenance Device of each system to make final

adjustment.

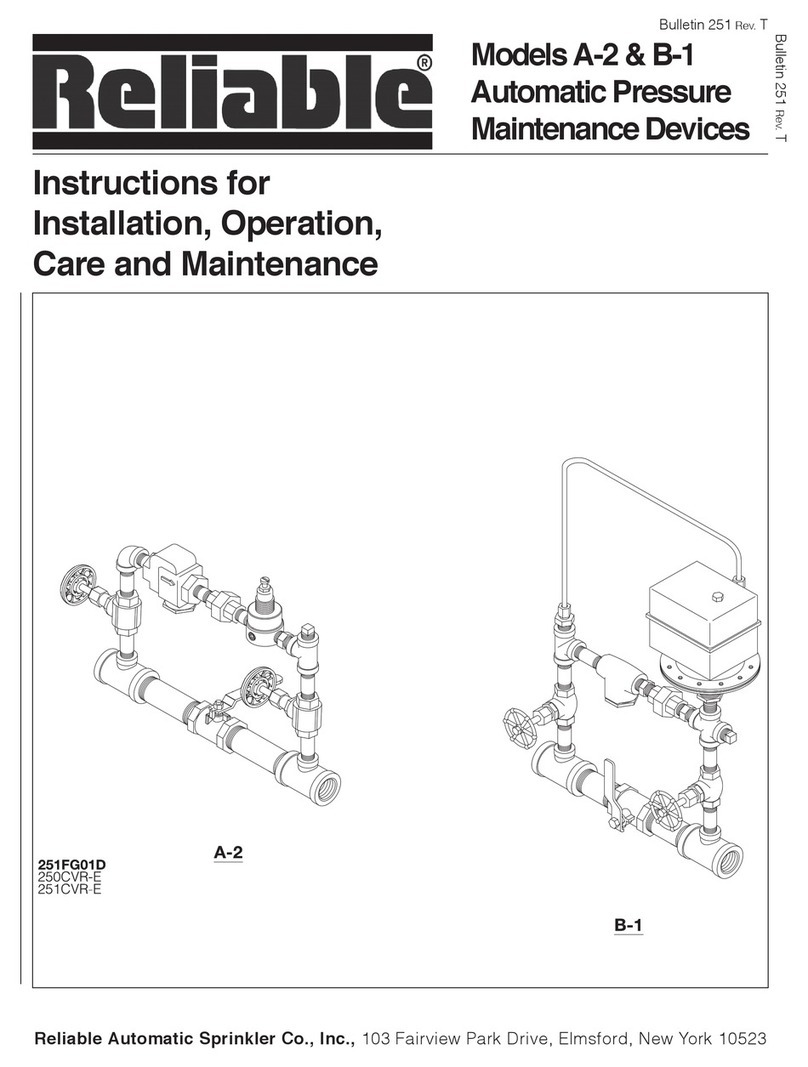

Model NS-ASAM Components Figure 2

Bulletin 254

May 2019

Page 3 of 7

www.reliablesprinkler.com