8.

Note: The dew point of the air must be maintained below the

lowest ambient temperature to which the double interlock

system piping will be exposed. Introduction of moisture into

the system piping that is exposed to freezing temperatures

can create ice blockage, which could prevent proper opera-

tion of the system. As minimum the supply of air should be

taken from refrigerated area at the lowest temperature. The air

supply system must be carefully designed to prevent plug-

ging by frost deposits. Special requirements such as those in

FME&R’S “Installation Guidelines for Refrigerated Storage”

may need to be incorporated.

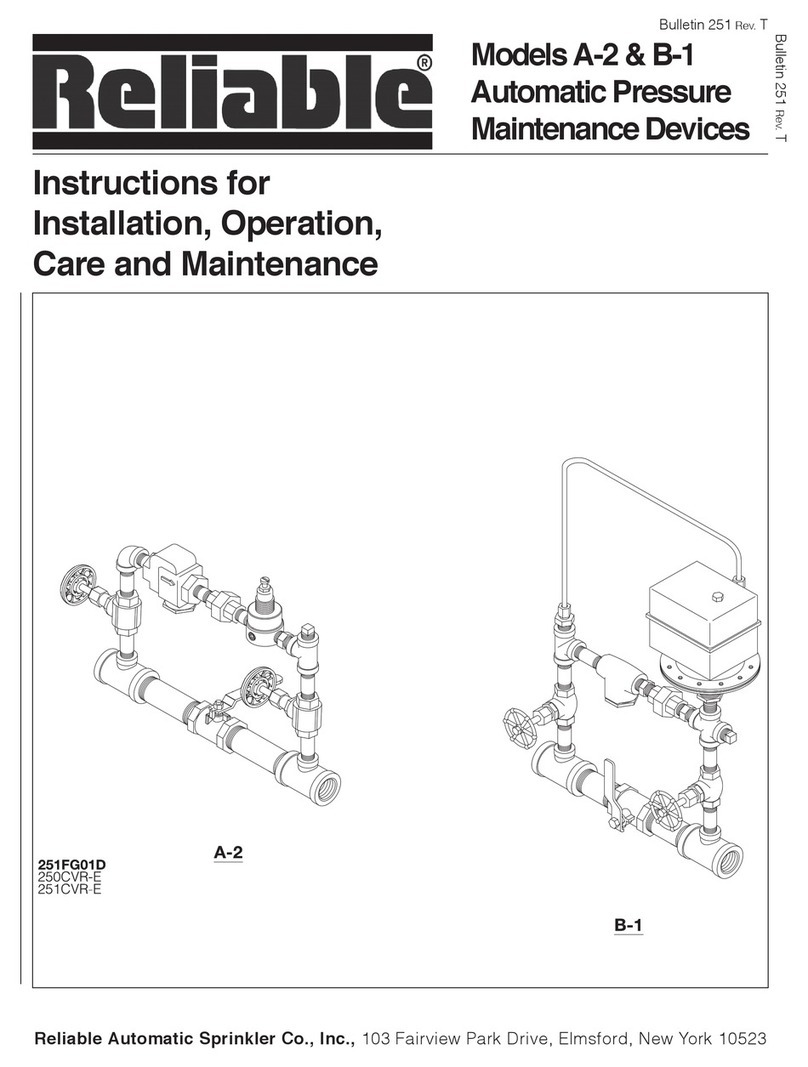

Whenever multiple Preaction Systems are installed at

the same location, it is strongly recomended that each

system have its own Model A-2 Pressure Maintenance

Device for individual maintenance of air pressure.

System Electrical Requirements

All releasing and detection devices in Type D Double

Interlock Preaction Systems are operated and supervised

by the Potter PFC-4410-RC Releasing/Control Panel in

accordance to the wiring diagram shown in fig. 4. The Re-

leasing/Control Panel should be set to use Program #11

(see Potter Instruction Manual #5403550).

The power supply, the standby emergency power

supply, battery charger, and the rectifier circuitry are

all contained within the Potter PFC-440-RC Releas-

ing/Control Panel. Batteries that provide ninety hours

of standby power are required for FM Approved sys-

tems.

The Model BNG-1 Manual Emergency Station can

be connected as a simple detector for fire annuncia-

tion, or the Model BNG-1F can be connected to both

zones for total system emergency manual operation.

The solenoid valve is operated and supervised by

the Potter PFC-4410-RC Releasing/Control Panel. The

Potter PFC-4410-RC Releasing/Control Panel requires

120 VAC.

Caution: Repairs or disassembly of the solenoid

valve should only be done by a trained technician. An

improperly repaired or partially assembled solenoid

valve could result in failure of the valve to operate.

Double Interlock Preaction System

Electric/Electric Actuation (Type D)

Engineering Specifications

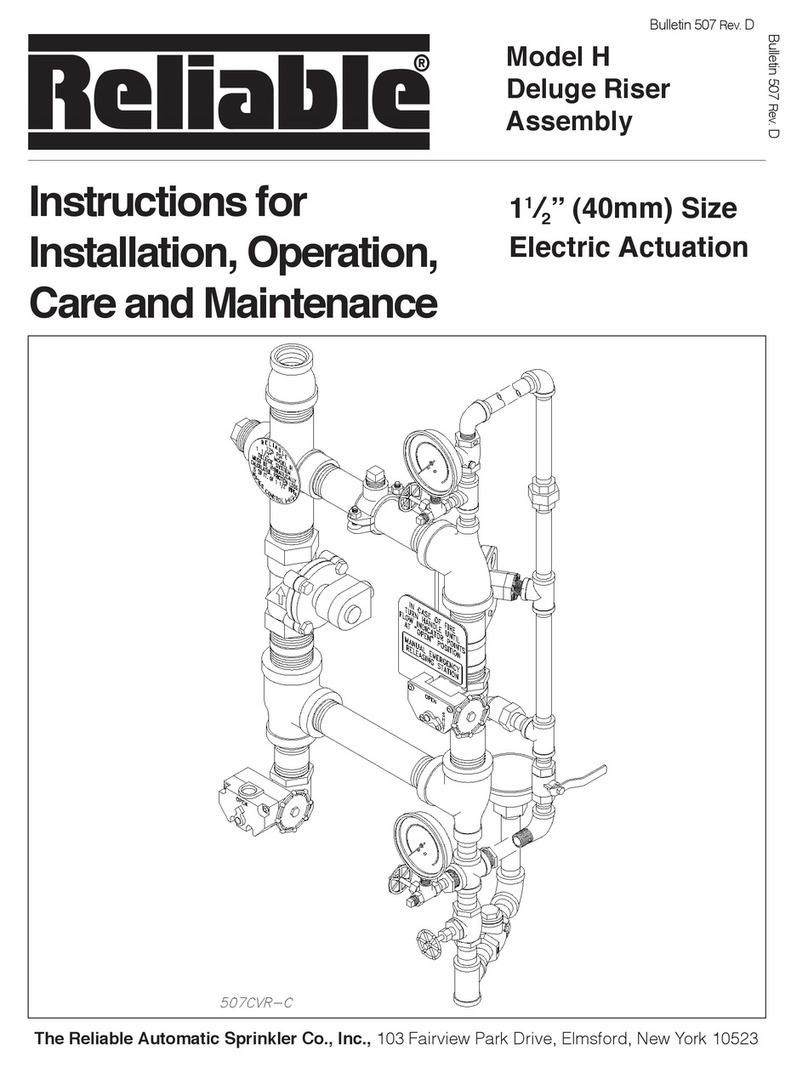

General Description

Preaction system shall be a double interlock preaction

system utilizing a 2” (50mm), 212” (65mm), 3" (80mm) and

76mm Reliable Model DDX Deluge Valve. Deluge Valve

shall be a [2” (50mm)] [212” (65mm)] [3” (80mm)] [76mm]

[cULus Listed] [Factory Mutual Approved] hydraulically

operated, differential latching clapper-type valve. Deluge

valve construction shall be of lightweight, ductile-iron con-

struction with “screw in” stainless steel seat and clapper

assembly. Stainless steel seat shall have O-ring seals to

resist leakage and corrosion. Clapper facing shall be

pressure actuated, providing a limited compression seat

for the sealing force between the clapper rubber facing

and the valve seat. Deluge valve shall have an external re-

set knob for resetting the clapper without requiring the re-

moval of the valve face plate. Push-rod chamber design

shall consist of a stainless steel piston/ push-rod and

spring assembly with diaphragm seal secured to the

casting through a push-rod guide constructed of a syn-

thetic engineering plastic to resist corrosion. Casting shall

have a bleeder hole located on the pushrod chamber for

air/water leakage indication. Trip ratio shall be approxi-

mately a 3:1 force differential. Deluge valve shall be of the

straight through design to minimize friction loss. Deluge

valve shall be activated by [hydraulic wet-pilot][low pres-

sure, pneumatic dry-pilot][electric] actuation trim. Inlet re-

striction orifice shall be factory installed into the inlet port of

the deluge valve push-rod cover plate and not be a sepa-

rate part of the deluge valve trim. End connection style to

be [2” (50mm), 2½” (65mm), 3” (80mm) or 76mm]

grooved inlet and grooved outlet, per ANSI/AWWA C606.

Deluge valve shall have a rated working pressure of 250

psi (17,2 bar) and shall be factory hydrostatic tested at

500 psi (34,5 bar). Deluge valve to be [2” (50mm)][2½”

(65mm)][3” (80mm)][76mm] Reliable Model DDX Deluge

Valve (Bulletin 513).

Valve trim shall be Type D electric/electric release trim

consisting of the following components:

•Hydraulic trim shall be galvanized and brass com-

ponents specifically Listed/Approved with the de-

luge valve, including associated pressure gauges,

1¼” drain connection, alarm device, alarm test, and

push-rod chamber connections.

•Electrical two-way, normally-closed, pilot-operated

solenoid valve [cULus Listed] [FM Approved] for its

intended use. The solenoid valve shall be con-

structed of a brass body with stainless steel sleeve

tube, springs, stop and plunger, and with ½” female

NPT end connections. Solenoid valve shall have a

maximum working pressure of [175 psi (12,1 bar)]

[250 psi (17,2 bar)] and maximum ambient temper-

ature rating of 150°F (66°C). Power consumption of

integrated coil shall be limited to [10watts (175 psi

(12,1 bar) Rated] [22 watts (250 psi (17,2 bar)

Rated] and require 24 VDC from a releasing/control

panel listed for such service. Solenoid valve shall be

a Skinner ½” normally-closed solenoid valve,

[Model 73218BN4UNLVNOC111C2 (175 psi (12,1

bar) Rated] [Model 73212BN4TNLVNOC322C2

(250 psi (17,2 bar) Rated].

•Low air pressure switch to indicate loss of air pres-

sure in system piping. Pressure switch shall be

[cULus Listed] [FM Approved] and of the bel-

lows-activated type enclosed in a weatherproof, 4x,

NEMA 4-rated enclosure incorporating tamper-re-

sistant screws. There shall be two sets of SPDT

(Form C) contacts rated at 10.0 A @ 125/250 VAC

and 2.5 A @ 6/12/24 VDC. The pressure switch shall

have a maximum service pressure rating of 250 psi

(17,2 bar) and shall be factory adjusted to operate at

apressureof4to8psi(0,27to0,55bar)withadjust

-

ment up to 20 psi (1,3 bar). Switch shall be provided

with a ½” NPT male pressure connection. Low air

alarm pressure switch shall be System Sensor

EPS10-2.

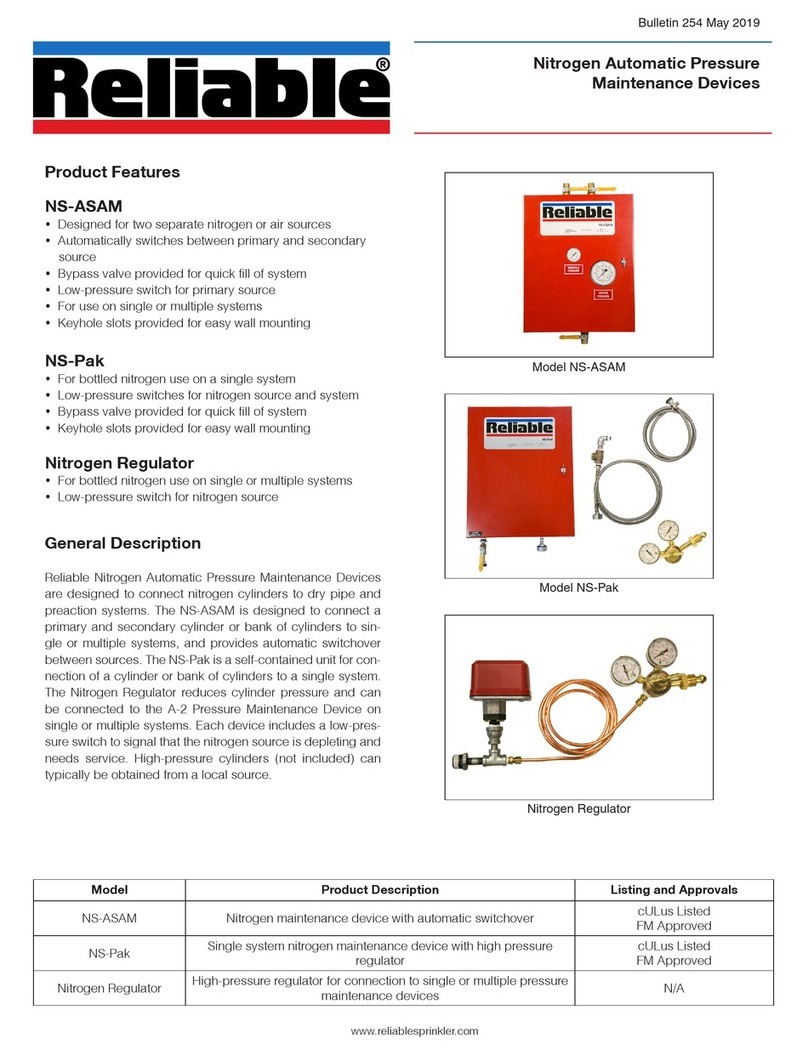

•Pressure maintenance device for maintaining a

constant system pneumatic pressure regardless of

pressure fluctuations in the compressed air (or nitro-

gen) source. The pressure maintenance device

shall consist of galvanized trim and brass parts, in-

cluding a strainer, a field adjustable air pressure

regulator, and associated pressure gauge. The

pressure regulator shall have an adjustable outlet