1

List of Figures

2

3

5

7

9

10

11

13

15

17

18

19

21

24

25

26

27

28

31

32

33

34

43

46

Standard Cabinet Dimensions

Nitrogen Generator Cabinet Dimensions

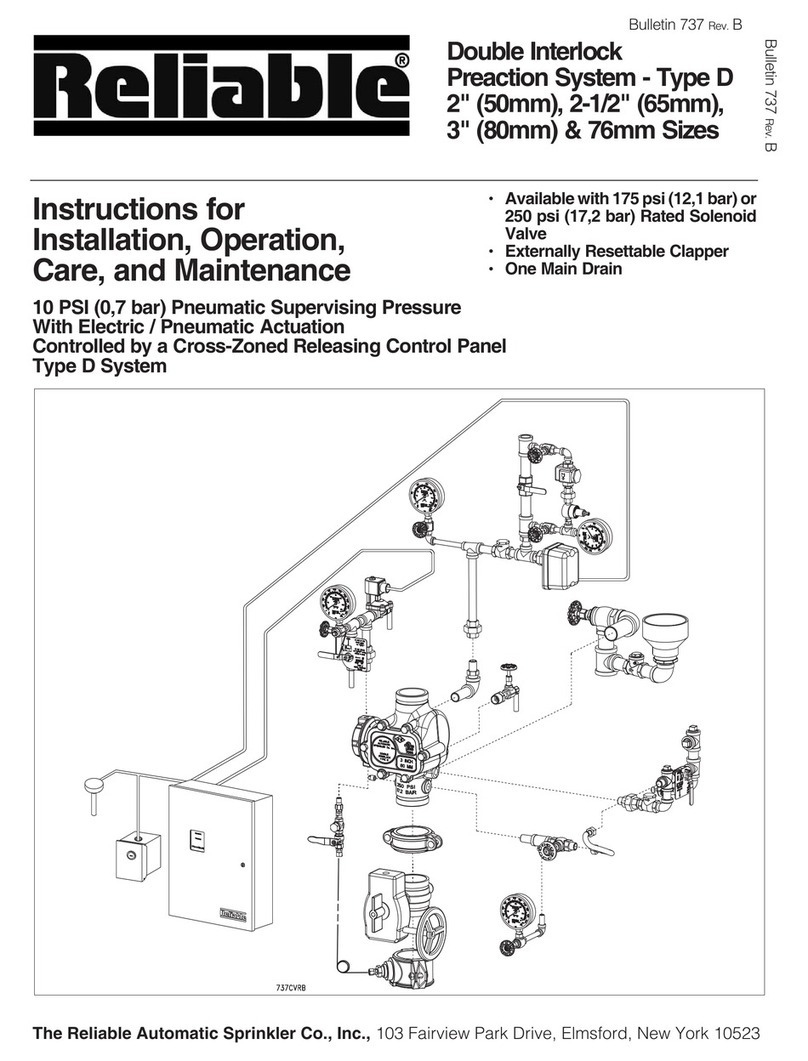

Type D Single, Double, Interlock Preaction Components

Type F Double Interlock Preaction Components

DDX-LP Dry System Components

Wet Pilot Line Limitations

Deluge Wet Pilot Line System Components

Deluge Dry Pilot Line System Components

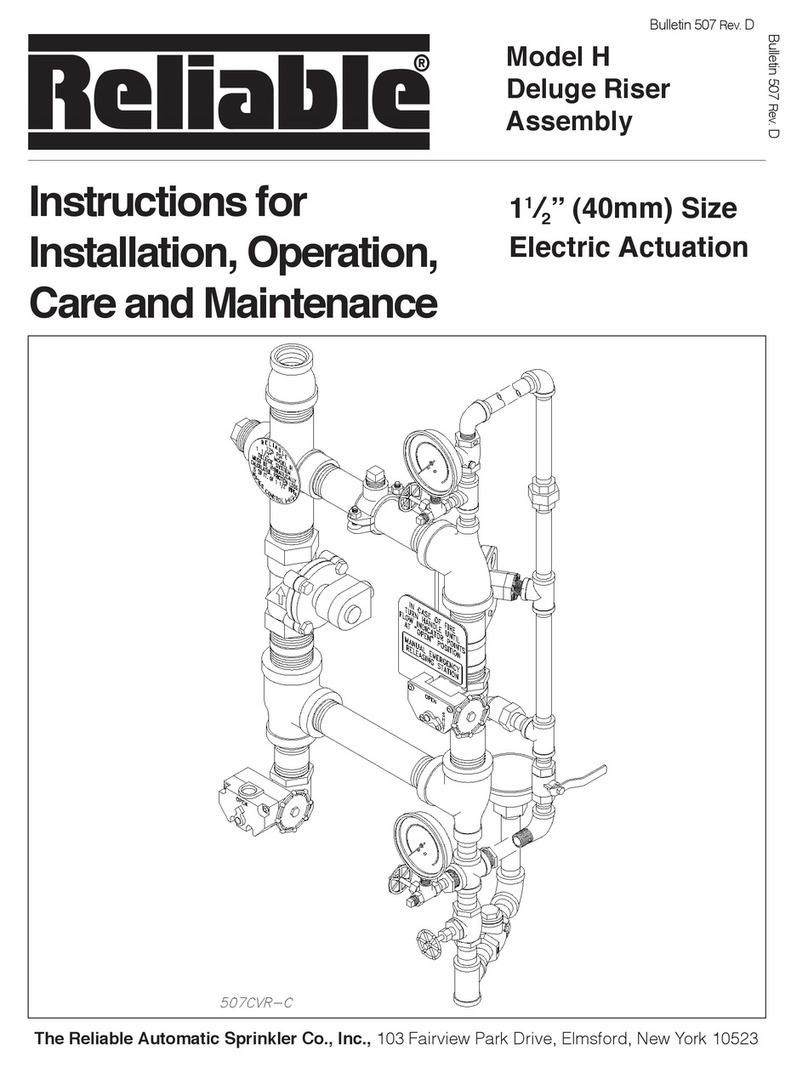

Deluge Electric Release System Components

Single Interlock Preaction Dry Pilot Line System Components

Wet Pilot Line Limitations

Single Interlock Preaction Wet Pilot Line System Components

Type PL Double Interlock Preaciton System Components

Factory Installed Electrical Devics

Potter PFC4410-RC Releasing Control Panel

Pressure & Tamper Switch Wiring

Solenoid and Air Compressor Wiring

Optional CoilKeeper™Wiring

24 VDC Terminal Block (Units with Integral Panel)

Class A Detector Circuit Wiring Example

Class B Detector Circuit Wiring Example

Output Device (Notication) Wiring Example

24VDC Terminal Block (Units without Integral Panel)

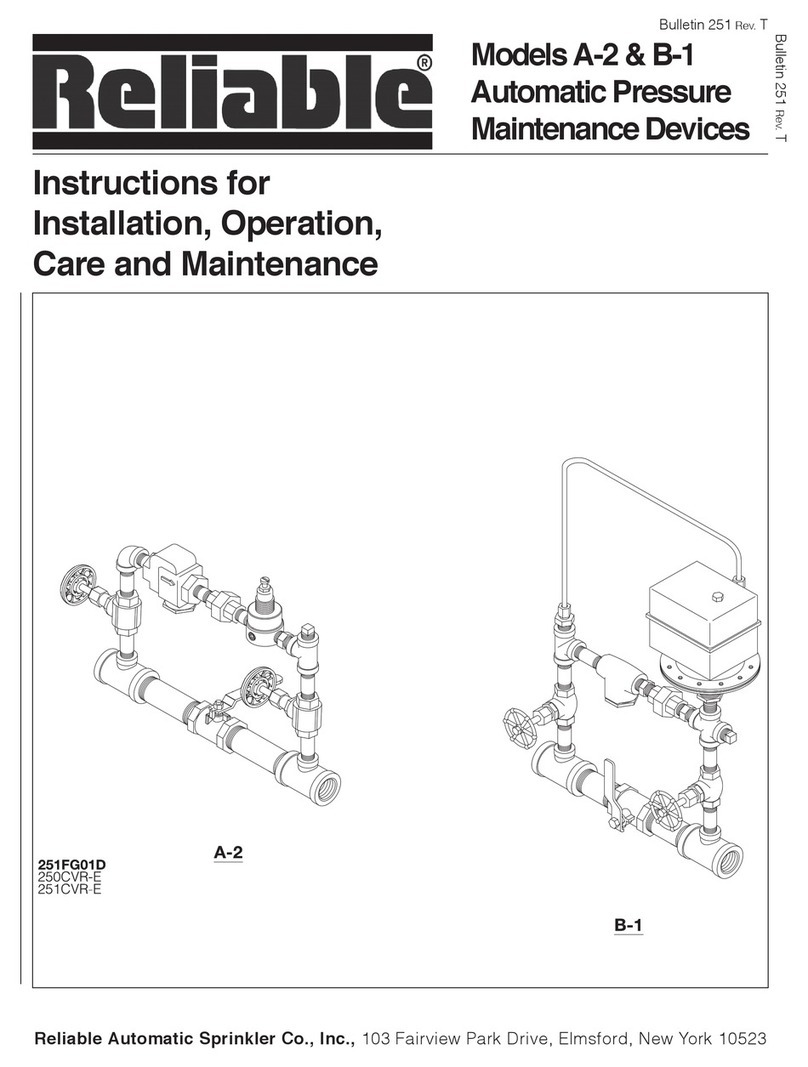

Supervisory Air/Nitrogen Pressure Requirements

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

Figure 13

Figure 14

Figure 15

Figure 16

Figure 17

Figure 18

Figure 19

Figure 20

Figure 21

Figure 22

Figure 23

Figure 24

Description Page

1. Introduction

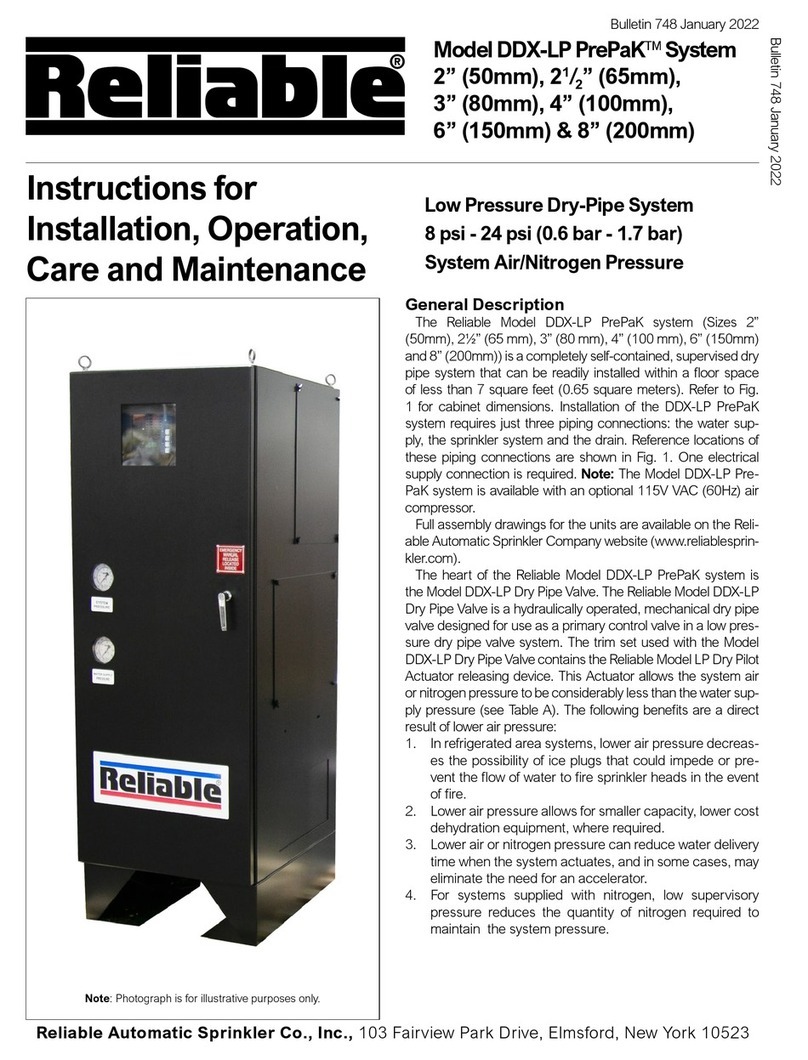

The Reliable Model DDX PrePaK™is a completely self-contained, supervised system that can be readily installed within a floor

space (not including door swing) of 4.7 ft2(0.43 m2) for 2” through 4” systems, and 6.5 ft2(0.60 m2) for 6” and 8” systems and

those systems incorporating a nitrogen generator.

Installation of the PrePaK™requires three piping connections: the water supply, the sprinkler system, and the drain. Reference

locations of these piping connections, along with general PrePaK™ dimensions are shown on gures 1 and 2 of this document.

Individual power circuits are required for the releasing control panel, air compressor, and nitrogen generator, where so

equipped. Depending on the type of system and requirements of the project, eld wiring of detection devices and noticaiton

devices may be required. When equipped with an integral releasing conrol panel, connection of the panel to the main building

re alarm system may also be required.

2. Scope

This document is intended to provide detailed information on the installation, operation, and maintenance of Reliable Model

DDX PrePaK™cabinet mounted systems. Basic information for the selection and ordering of units is provided on technical

bulletin 760 that is available on the Reliable website (www.reliablesprinkler.com).

This document does not contain information on the design, applicability, or installation of the automatic re detection system

that may be necessary for complete operation of the system. Design and installation of re detection and alarm systems must

be performed by qualied design professionals and approved by all authorities having jurisdiction.

This document is not intended to replace or revise any requirements of the National Fire Protection Association (NFPA), FM

Global, and/or any authorities having jurisdiction (AHJ) that may govern an installation. Design and installation requirements

for re protection systems must be independently evaluated by qualied design professionals and approved by all authorities

having jurisdiction.

3. Product Descriptions & References

Pages 4 through 21 provide descriptions of each available system, additional (related) product references, and diagrams of

major system components. Full assembly drawings are available on the Reliable website (www.reliablesprinkler.com).

ii.