The Reliable Automatic Sprinkler Co., Inc.

(800) 431-1588 Sales Offices

(800) 848-6051 Sales Fax

(914) 829-2042 Corporate Offices

www.reliablesprinkler.com Internet Address

Manufactured by

Recycled

Paper

Revision lines indicate updated or new data.

EG. Printed in U.S.A. 10/13 P/N 9999970164

The equipment presented in this bulletin is to be installed in accordance with the latest published Standards of the National Fire Protection Association, Factory

Mutual Research Corporation, or other similar organizations and also with the provisions of governmental codes or ordinances whenever applicable.

Products manufactured and distributed by Reliable have been protecting life and property for over 90 years, and are installed and serviced by the most highly

qualified and reputable sprinkler contractors located throughout the United States, Canada and foreign countries.

Installation

Quick response sprinklers are intended for installation as

specified in NFPA 13. Quick response sprinklers and stan-

dard response sprinklers should not be intermixed.

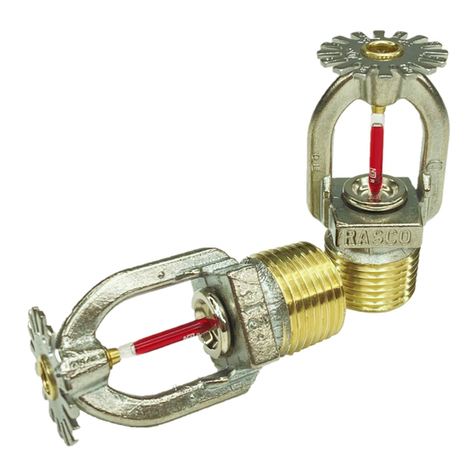

The Model F1FR-300 QREC and QREC-9 Recessed Sprin-

klers are to be installed as illustrated. The Model F1 or F2

escutcheons illustrated are the only recessed escutcheons

to be used with the these sprinklers. The use of any other

recessed escutcheon will void all approvals and negate all

warranties.

When installing Model F1FR-300 QREC Pendent and

QREC-9 Horizontal Sidewall Sprinklers, use the Model D

Sprinkler Wrench. When installing F1FR-300 QREC Re-

cessed Pendent and F1FR-300 QREC-9 Recessed Horizon-

tal Sidewall Sprinkler, use the Model GFR1 Sprinkler Wrench.

Any other type of wrench may damage these sprinklers.

Glass bulb sprinklers have orange bulb protectors to

minimize bulb damage during shipping, handling and in-

stallation. REMOVE THIS PROTECTION AT THE TIME THE

SPRINKLER SYSTEM IS PLACED IN SERVICE FOR FIRE

PROTECTION. Removal of the protectors before this time

may leave the bulb vulnerable to damage. RASCO wrench-

es are designed to install sprinklers when covers are in

place. REMOVE PROTECTORS BY UNDOING THE CLASP

BY HAND. DO NOT USE TOOLS TO REMOVE THE PRO-

TECTORS.

Maintenance

Model F1FR-300 Extended Coverage Sprinklers should

be inspected and the sprinkler system maintained in accor-

dance with NFPA 25. Do not clean sprinklers with soap and

water, ammonia or any other cleaning fluids. Remove dust

by using a soft brush or gentle vacuuming. Remove any

sprinkler that has been painted (other than factory applied)

or damaged in any way. A stock of spare sprinklers should

be maintained to allow quick replacement of damage or op-

erated sprinklers. Prior to installation, sprinklers should be

maintained in the original cartons and packaging until used

to minimize the potential for damage to sprinklers that would

cause improper operation or non-operation.

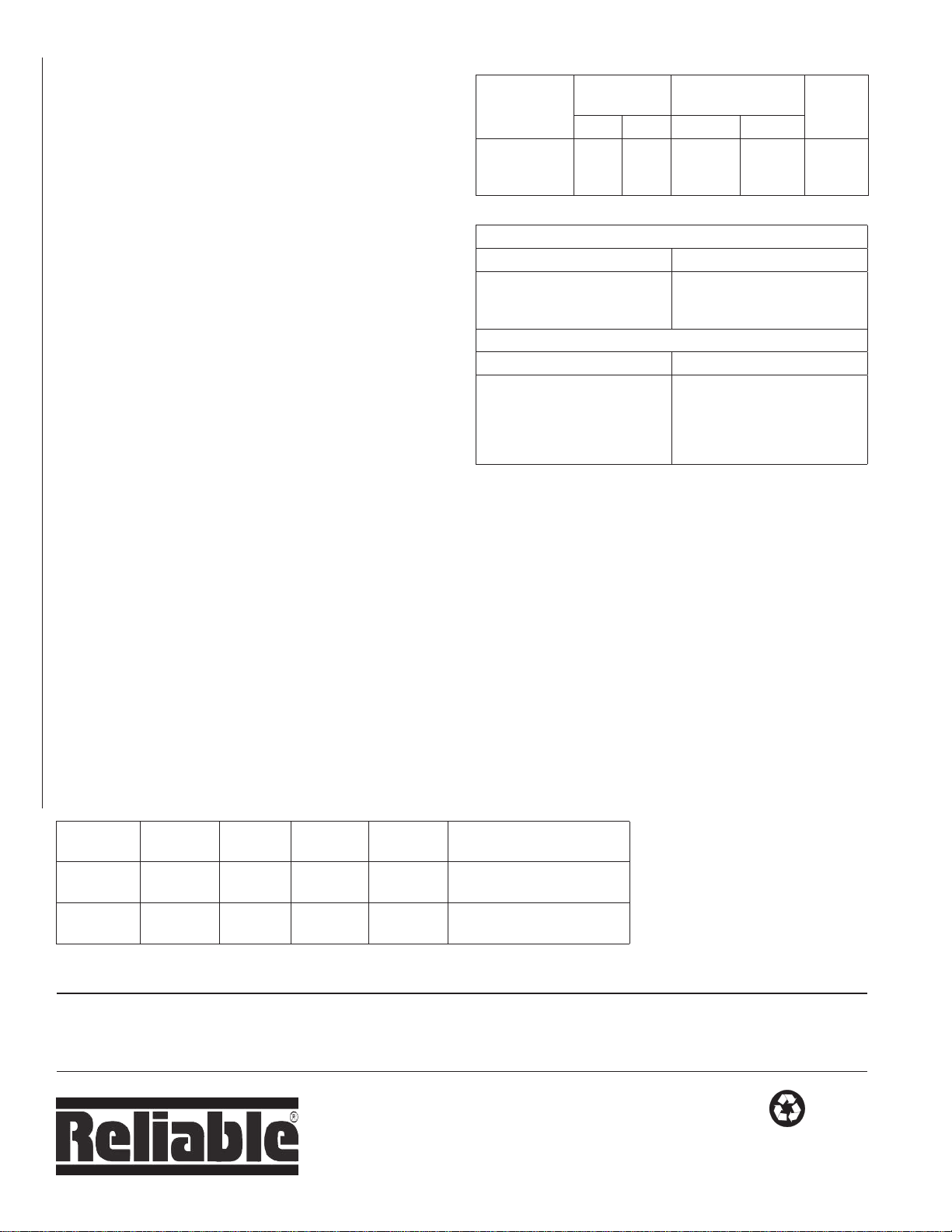

Temperature Ratings

Classification Sprinkler

Temperature Maximum Ambient

Temp. Bulb

Color

°F °C °F °C

Ordinary

Ordinary

Intermediate

135

155

175

57

68

79

100

100

150

38

38

66

Orange

Red

Yellow

Finishes(1)

Standard Finishes

Sprinkler Escutcheon

Bronze

Chrome

White Polyester Coated

Brass

Chrome

White Painted

Special Application Finishes

Sprinkler Escutcheon

Bright Brass

Black Plated

Black Paint

Off White

Satin Chrome

Bright Brass

Black Plated

Black Paint

Off White

Satin Chrome

(1) Other colors and finishes are available on special order.

Consult factory for details

Escutcheon Data

Sprinkler

Type Escutcheon

Model Approvals Adjustment “A”

Dimension FaceofFittingtoCeilingor

WallDimensions

F1FR-300

QREC Pend F1 1, 2 ¾” (19mm) ¾” (19mm)

3/16 to 15/16

(5mm to 24mm)

F1FR-300

QREC-9 HSW F2 1, 2 ¾” (19mm) 1” (35mm)

3/16” to 11/16”

(5mm to 18mm)

Ordering Information

Specify:

1. Sprinkler Model

2. Sprinkler Type

3. Orifice Size

4. Deflector Type

5. Temperature Rating

6. Sprinkler Finish

7. Escutcheon Type

8. Escutcheon Finish (where applicable)

Note: When Recessed sprinklers are ordered, the sprin-

klers and escutcheons are packaged separately.